1.01.02 Evaporation - K-Patents

1.01.02 Evaporation - K-Patents

1.01.02 Evaporation - K-Patents

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

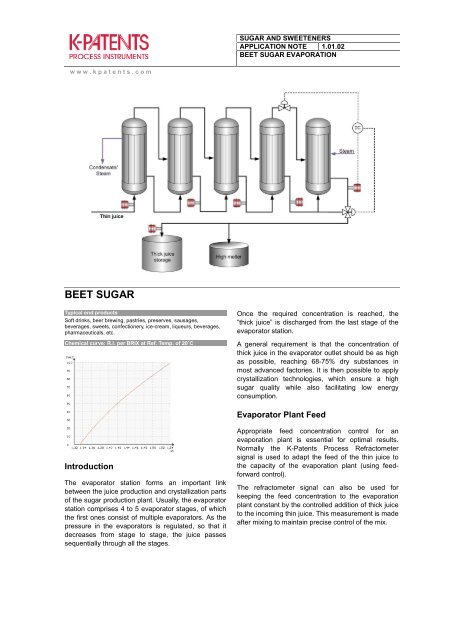

SUGAR AND SWEETENERSAPPLICATION NOTE <strong>1.01.02</strong>BEET SUGAR EVAPORATIONw w w . k p a t e n t s . c o mBEET SUGARTypical end productsSoft drinks, beer brewing, pastries, preserves, sausages,beverages, sweets, confectionery, ice-cream, liqueurs, beverages,pharmaceuticals, etc.Chemical curve: R.I. per BRIX at Ref. Temp. of 20˚COnce the required concentration is reached, the“thick juice” is discharged from the last stage of theevaporator station.A general requirement is that the concentration ofthick juice in the evaporator outlet should be as highas possible, reaching 68-75% dry substances inmost advanced factories. It is then possible to applycrystallization technologies, which ensure a highsugar quality while also facilitating low energyconsumption.Evaporator Plant FeedIntroductionThe evaporator station forms an important linkbetween the juice production and crystallization partsof the sugar production plant. Usually, the evaporatorstation comprises 4 to 5 evaporator stages, of whichthe first ones consist of multiple evaporators. As thepressure in the evaporators is regulated, so that itdecreases from stage to stage, the juice passessequentially through all the stages.Appropriate feed concentration control for anevaporation plant is essential for optimal results.Normally the K-<strong>Patents</strong> Process Refractometersignal is used to adapt the feed of the thin juice tothe capacity of the evaporation plant (using feedforwardcontrol).The refractometer signal can also be used forkeeping the feed concentration to the evaporationplant constant by the controlled addition of thick juiceto the incoming thin juice. This measurement is madeafter mixing to maintain precise control of the mix.

SUGAR AND SWEETENERSAPPLICATION NOTE <strong>1.01.02</strong>BEET SUGAR EVAPORATIONw w w . k p a t e n t s . c o mEvaporator Plant Outlet andIntermediate Effects Control<strong>Evaporation</strong> in the multiple effect evaporation plant ismore cost effective than in the crystallizer, whicheconomically justifies an evaporation control system.The K-<strong>Patents</strong> Process Refractometer is not onlyused after the final evaporation stage, but also afterthe intermediate stages. The refractometer is alsoused in a control loop, which keeps the thick juiceconcentration constant by regulating the steam flowor the quantity of thick juice re-circulated to theevaporators. As a result, the specific energyconsumption can be minimized.Thick Juice to Storage TankIn this application, the Process Refractometer helpsto maximize the storage capacity by keeping thethick juice at as high a concentration level aspossible.Instrumentation and InstallationThe K-<strong>Patents</strong> Process Refractometer PR-23-GP isan ideal instrument for measuring Brix in thedemanding beet sugar evaporation process. ThePR-23-GP sensor is installed via a flange or a clampconnection.Lime residuals and other additives may coat theprism and an automatic steam wash isrecommended in the thin juice applications with atypical range of 0 - 25 Brix.In some plants, the thick juice also containssupersaturated impurities (e.g. oxalic acid), whichmay crystallize on the prism. Therefore an automaticsteam wash may be necessary. In extreme cases,the K-<strong>Patents</strong> refractometer has been installed in anarrower by-pass line flowing from a cooling heatexchanger,where the impurities crystallize.Because of its digital sensing technology, theK-<strong>Patents</strong> refractometer can measure dissolvedsugar and be uninfluenced by the presence ofundissolved particles or crystals.InstrumentationDescriptionK-<strong>Patents</strong> Process Refractometer PR-23-GP is an industrial refractometer forlarge pipe sizes and tanks, cookers, crystallizers and kettles. Installation througha flange or clamp connection.Automatic prism wash:Prism wash with steam: The components of a steam wash system are asensor with integral steam nozzle mounted at the sensor head, a shut-off valvefor steam line and an indicating transmitter equipped with relays to drive thewash valves.Prism wash with high pressure water: The components of a high pressure watersystem are a sensor with integral water nozzle mounted at the sensor head, ahigh pressure pump together with a power relay unit and an indicating transmitterequipped with relays. The power relay unit drives the high-pressure pump andwater valve. In high pressure wash systems, pressure increase can occur in aclosed pipe section when the high pressure pump is operated. Thereforemounting a pressure relief valve in the pipe section is recommended. Reliefpressure should be set according to the pipe pressure rating.Measurement range:The inbuilt relays of the indicating transmitter can be configured to control theprism wash cycles.Refractive Index (nD) 1.3200 – 1.5300, corresponding to 0-100 Brix.