Electro filter.pdf - Siemens

Electro filter.pdf - Siemens

Electro filter.pdf - Siemens

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

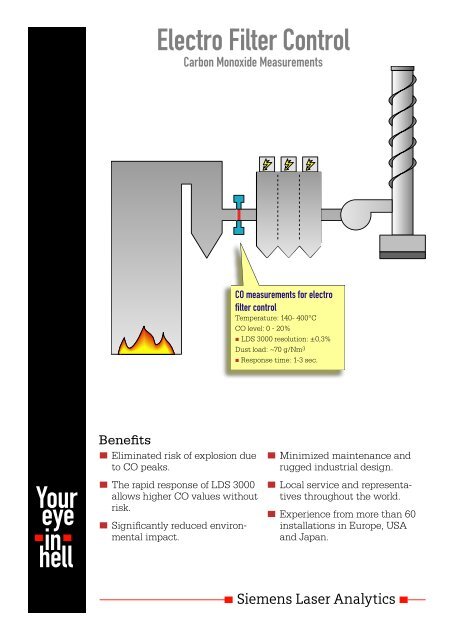

<strong>Electro</strong> Filter Control<br />

Carbon Monoxide Measurements<br />

CO measurements for electro<br />

<strong>filter</strong> control<br />

Temperature: 140- 400°C<br />

CO level: 0 - 20%<br />

• LDS 3000 resolution: ±0,3%<br />

Dust load: ~70 g/Nm 3<br />

• Response time: 1-3 sec.<br />

Your<br />

eye<br />

in<br />

hell<br />

Benefits<br />

• Eliminated risk of explosion due<br />

to CO peaks.<br />

• The rapid response of LDS 3000<br />

allows higher CO values without<br />

risk.<br />

• Significantly reduced environmental<br />

impact.<br />

• Minimized maintenance and<br />

rugged industrial design.<br />

• Local service and representatives<br />

throughout the world.<br />

• Experience from more than 60<br />

installations in Europe, USA<br />

and Japan.<br />

<strong>Siemens</strong> Laser Analytics

Measuring CO for <strong>Electro</strong> Filter Control<br />

Introduction<br />

<strong>Siemens</strong> Laser Analytics provides analysers for process<br />

control applications based on tunable diode laser. Our focus<br />

on ammonia analysers started in the late eighties due to<br />

the very early Swedish deNO x legislation. One very critical<br />

parameter for the total efficiency of a deNO x installation is<br />

the control of the ammonia slip.<br />

We made our first high performance installation 1992 to<br />

measure ammonia in the range 0-10 ppm with an accuracy<br />

of ±0,5 ppm. Since then we have improved the technology<br />

and made approximately 60 permanent installations.<br />

Central unit<br />

LDS 3000<br />

Laser Diode Spectrometer<br />

Transmitter<br />

System set-up<br />

Receiver<br />

Installation and Operation<br />

Our LDS 3000 is very easy to install and operate. The<br />

analyser is designed to handle the very rough industrial<br />

environment consisting of high temperature, electromagnetic<br />

fields, high dust loads, etc. The system is composed<br />

of three parts.<br />

• The central unit<br />

• Hybrid cable<br />

• The sensor<br />

The transmitter and the receiver in the sensor are interconnected<br />

with a loop cable and the sensor is connected to the<br />

central unit with a hybrid cable containing fibre optics. The<br />

length of this cable can exceed 1 km.<br />

Features<br />

The system has a lot of unique points which makes it very<br />

suitable for long term process operation.<br />

• Built in calibration<br />

• Dynamic dust load compensation<br />

• Selectable range<br />

• No gas sampling - in-situ measurements<br />

• Three measuring points simultaneously<br />

• High temperature range up to 600°C<br />

Hybrid cable<br />

Loop cable<br />

CO and electro <strong>filter</strong><br />

Cement manufacturing plants and hazardous waste incinerators<br />

are using electro <strong>filter</strong>s to eliminate/trap particles.<br />

Within the processes, CO can sometimes occur at critical<br />

levels.<br />

If the presence of CO in the electro <strong>filter</strong>s exceeds a certain<br />

level (normally around 10%), electric sparks can provoke<br />

dangerous explosions. Beside the risk for personal damages,<br />

an explosion means a considerable financial loss,<br />

since the electro <strong>filter</strong> has to be replaced.<br />

Manufacturers of cement are today normally measuring CO<br />

on stack. If the CO level exceeds 1-3%, the electro <strong>filter</strong> is<br />

shut down because of the threat of explosions. This leads to<br />

un<strong>filter</strong>ed emissions and contaminated plant surroundings.<br />

Often shutdowns at these levels are unnecessary since the<br />

CO rarely will reach the critical 10%.<br />

The installation of LDS 3000, measuring CO just before<br />

or in the electro <strong>filter</strong> with high accuracy and a response<br />

time of 1-3 seconds, will considerably improve the control<br />

of the electro <strong>filter</strong>. The electro <strong>filter</strong> can immediately be<br />

shut down automatically when the CO levels reaches for<br />

example 6-8%.<br />

Calibration<br />

Due to the stability of the detection method used in LDS<br />

3000 maintenance calibration of the system is not necessary.<br />

Verifying calibrations made by <strong>Siemens</strong> Laser Analytics<br />

on old installations have shown that calibration state of<br />

LDS 3000 is very stable and not subject to long term drifts.<br />

Zero point calibrations are never done.<br />

References (complete on the web)<br />

BASF Germany 1998<br />

Chemical plant • Particle <strong>filter</strong> • 0-20% • ±0,3%<br />

Alsen AG Germany 1999<br />

Cement industry • Particle <strong>filter</strong> • 0-20% • ±0,3%<br />

Contact<br />

<strong>Siemens</strong> Laser Analytics (headquarters)<br />

Marketing Director<br />

Jan Grimbrandt • jan.grimbrandt@siemens.com<br />

Marketing Assistant<br />

Michaela Hermansson • michaela.hermansson@siemens.com<br />

Phone: +46 (0)31 776 86 00<br />

<strong>Siemens</strong> Laser Analytics objective is not only to supply gas analysers measuring different gases in complicated<br />

and hostile environments – we also want to participate in managing difficult processes containing<br />

gas compounds by adding know-how, experience and professionallity in every aspect of the measurement.<br />

<strong>Siemens</strong> Laser Analytics<br />

<strong>Siemens</strong> Laser Analytics AB • Box 5065 • SE-402 22 Göteborg • Sweden • www.siemens.se/sla