A Brief Bit of EDM History

The electrical discharge machining (EDM) process as we know it today started with the observations of Joseph Preistly in 1770. He noticed that electrical discharges had removed material from the electrodes in his experiments. This is also known as electro-discharge erosion.

In the 1940s two Soviet researchers, the Lazarenkos, developed a machining process that formed the foundation for modern wire EDM and small hole EDM. Practical electrical discharge machines were eventually developed, using more powerful pulse generators, automatic repeated discharge and steady dielectric fluid flow to control the process.

EDM is also known as: spark machining, spark eroding, and die sinking.

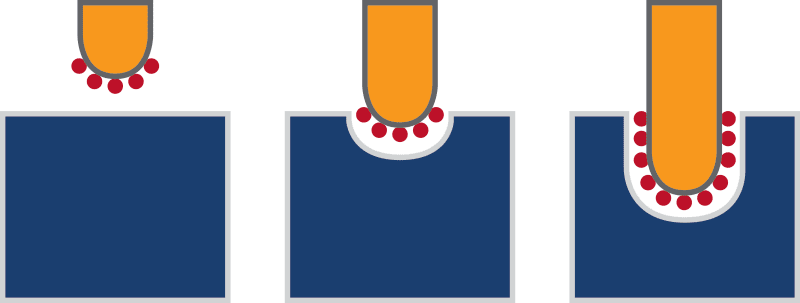

The tool electrode (upper) and workpiece electrode (lower) are connected to a power supply which generates electrical potential between them.

How Electrical Discharge Machining Works

The basic electrical discharge machining process is really quite simple. An electrical discharge (spark) is created between two electrodes (solid electric conductors). The tool electrode is typically referred to as the electrode, and the workpiece electrode as the workpiece. The spark is visible evidence of the flow of electricity. This electric spark produces intense heat with temperatures reaching 8000 to 12000 degrees Celsius, melting/vaporizing almost any conductive material. These rapid, repeated electrical current discharges take place in a very small gap between the two electrodes, which never come in contact with each other. The spark gap (aka discharge gap, electrode gap) is maintained by adaptive machine controls to ensure a constant, stable distance as the electric discharge occurs up to millions of times per second.

Illustration of electric discharge machining. The electrode (yellow) moves closer to the workpiece (blue) as the electric discharge (red) erodes the workpiece material. Machine automation maintains the spark gap so the process is continuous.

The spark is very precisely controlled and localized so it only affects the surface of the material. The EDM process usually does not affect the heat treat below the surface. Both the tool and workpiece are submerged in dielectric (not conductive) fluid, typically deionized water.

The spark always takes place in the dielectric fluid. The conductivity of the deionized water is carefully controlled, creating an ideal environment for the EDM process. The deionized water also provides cooling during the machining process, and flushes away the tiny eroded metal particles.

Electrical discharge machining is considered a non-traditional machining method because it uses electric discharge to remove material from the workpiece. This is in contrast to traditional machining methods such as drilling or grinding which use mechanical force to remove material.

What is Wire Electrical Discharge Machining?

Wire EDM is also known as: wire-cut EDM, wire cutting, EDN cutting, EDM wire cutting, wire burning, wire erosion, wire eroding, wire cut electric discharge machining, and ‘cheese-cutter’ EDM.

Wire electrical discharge machining (WEDM) uses a metallic wire to cut or shape a workpiece, often a conductive material, with a thin electrode wire that follows a precisely programmed path. Typically the electrode diameters range from .004″ – .012″ (.10mm – .30mm), although smaller and larger diameters are available.

During the wire cutting process there is no direct contact between the wire and the workpiece which allows for machining without causing any distortion in the path of the wire, or the shape of the material. To accomplish this, the wire is very rapidly charged to a desired voltage. The wire is also surrounded by deionized water. When the voltage reaches the correct level, a spark jumps the gap and melts a small portion of the work piece. The deionized water cools and flushes away the small particles from the gap.

The hardness of the work piece material has no detrimental effect on the cutting speed. Extrusion dies and blanking punches are very often machined by wire cutting.

How Wire EDM Works – A basic introduction to the wire EDM process.

Wire Cutting

Illustration of wire EDM cutting. The electrode wire is held between upper and lower guides which control axis movements.

How Wire-Cut EDM Works

EDM cutting is always through the entire workpiece. To start wire machining it is first necessary to drill a hole in the workpiece or start from the edge. On the machining area, each discharge creates a crater in the workpiece and an impact on the tool. The wire can be inclined, thus making it possible to make parts with taper or with different profiles at the top and bottom. There is never any mechanical contact between the electrode and workpiece (see above). The wire is usually made of brass or stratified copper, and is between 0.1 and 0.3 mm diameter.

Depending on the accuracy and surface finish needed, a part will either be one cut or it will be roughed and skimmed. On a one cut the wire ideally passes through a solid part and drops a slug or scrap piece when it is done. This will give adequate accuracy for some jobs, but most of the time, skimming is necessary.

Roughing & Skim Cuts

A skim cut is where the wire is passed back over the roughed surface again with a lower power setting and low pressure flush. There can be from one to nine skim passes depending on the accuracy and surface finish required. Usually there are just two skim passes. A skim pass can remove as much as 0.002″ of material or a as little as 0.0001″. During roughing ( i.e. the first cut) the water is forced into the cut at high pressure in order to provide plenty of cooling and eliminate eroded particles as fast as possible. During skimming (accuracy / finish cuts) the water is gently flowed over the burn so as not to deflect the wire.

Capabilities of EDM – An advanced look at wire and high-speed small hole EDM.

What types of shapes can a wire EDM machine produce?

A wire EDM machine is a type of CNC machine that can move along four independent axes to generate taper cuts. For example, a stamping die can be machined with 1/4 degree taper or a mold with one degree taper in some areas and two degrees in another with precision. Extrusion dies or nozzles and horns can be cut with constantly changing tapers. For example, a detailed shape on the top of the work piece can transition to a simple circle on the bottom.

Uses for EDM Cutting

Our wire cut EDM services are ideal for delicate or small work pieces that may be damaged during conventional machining or other traditional techniques:

- Thick parts requiring good finishes and/or accuracies.

- Complex shapes or narrow slots

- Larger parts that need to hold accurate tolerances

- Delicate, hard, exotic/expensive or weak materials

How Does Small Hole EDM Work?

High-speed small hole electrical discharge machining is a specialized field of electrical discharge machining. A small .010″ – .118″ dia. (.25mm – 3.0mm), usually hollow electrode, spins about a spindle much like a drill and drill bit (EDM drill). The electrode is electrically charged by a servo-controlled generator producing the spark. Water based dielectric flushes through and around the electrode providing a controlled environment for the extremely small sparks to jump to the workpiece.

The sparks erode the surface of the workpiece creating very small pockets. Eventually millions and millions of these microscopic pockets create the small hole. The size of the hole is controlled by the diameter of the electrode and the power settings. The location and depth of the holes are driven by CNC ISO codes eliminating operator error. The machines available at XACT have automatic electrode changers for efficient unattended machining.