When you need to remove a few pieces of metal quickly, the cold chisel is king. It easily chops through metal screws, bolts, rivets, brackets, and nails. On a recent plumbing job, I removed the remains of an old mounting flange, lead, and oakum using a sharp cold chisel. It took only seconds and I didn’t have to waste time setting up a reciprocating saw or angle grinder.

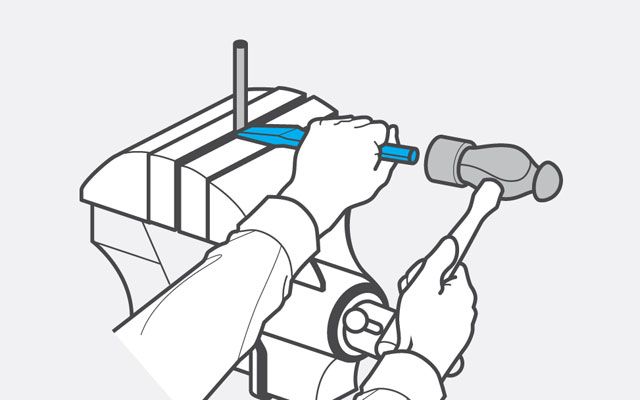

Always use a cold chisel that’s slightly wider than what you’re cutting. Wet the chisel’s edge with a drop of machine oil. That lubrication helps it slip through hardened metal grains. Hold the chisel with your thumb and index finger (as shown), place the edge on the metal, and strike it with a ball-peen hammer. Don’t use a claw hammer—the heads aren’t tempered for striking hard metal and can chip. Once the metal is notched, you can usually snap it off. Total time invested should be 30 seconds or less.

I’ve owned two American-made Craftsman cold chisels for at least 20 years—Enderes and Dasco also make fine chisels. One is 1/4 inch wide and the other is 3/4 inch. I sharpen them with a second-cut file (medium-coarse). And when one gets chewed up, I grind a fresh edge with a 60-grit white aluminum oxide wheel and hone it on a coarse water stone. I expect they’ll last another 20.

Cold Chisel Cheat Sheet

1. Wear safety glasses, and use a chisel that's 25 percent wider than what you're cutting.

2. Sharpen the chisel to a 60- to 70-degree bevel. It takes just a few seconds on a grinder to refresh the cutting edges.

3. Apply a little 30-weight oil to the cutting edges before use. This reduces friction, which increases the tool's cutting ability.

4. Position the workpiece in the middle of the jaws and tighten the vise firmly. This is not a task for a dainty vise; use a heavy-duty bench model.

5. To maximize the power of each strike, align the chisel with the vise's screw and cut perpendicular to the jaws.

6. Don't use a chisel with a damaged end. Grind off any curled metal before it splinters off.

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.