In the March 1968 issue, Popular Mechanics wrote about a major evolution in aviation—the Concorde. But the commercial supersonic jet's fuel-guzzling design, limited routes, and pricey airfare eventually doomed the era of supersonic travel. Fifty years later, the dream is still alive with companies like Boom set to reveal their quiet supersonic prototype in October 2020. Is supersonic travel finally here or will history repeat itself?

You sit in London Airport at one o'clock and eat a leisurely lunch of roast English beef and Yorkshire pudding; soon, your flight is called. You enter a long, pencil-slim fuselage. You buckle your seat belt. After 15 minutes-and 140 miles-of flight, you pass through the sound barrier, although you hear nothing. And, since the engine noise never catches up with you, you cruise silently 12 miles above the Atlantic; each second, you travel nearly half a mile.

The globe is barely visible; the whole sky is a deep but delicate purple, a Concorde sky. Before long, you are landing in New York; and, as you adjust your watch after the 3 1/4-hour flight, you land at Kennedy International Airport at noon—in time for lunch again.

In three years, such a travelers' dream will become real. Soon, Concorde prototype 001 should take to the air; by 1971 the planes will be in commercial service. Every man, woman, and child will be able to fly supersonic, and airlines will issue distinctive badges to passengers proving that they've been through the sound barrier. Until now, it has been the privilege of military and test pilots only.

More than 12 years ago, the British and French governments met to discuss the joint development of such an aircraft, once the passage through the sound barrier was proved to hold no terrors. The cost of development was colossal. Originally estimated at $450 million, the project is now put at $1.5 billion—about $15 a head for the population of the two countries. (The American supersonic airliner will probably cost three times as much.)

The cost per plane has been estimated at from 18 to $20 million. Even so, there is some doubt that the development costs will ever be recovered. France and Britain regard it as a way to earn prestige, new knowledge in the fields of computers and electronics, and billions in foreign currency. You, the Concorde traveler, may thus revel in a highly subsidized bargain.

The Concorde is unique as an international venture. It's the sort of brave partnership normally attempted only in the emergency of wartime.

Nominally, France and England each builds an equal number of the planes. In practice, all the wings, center sections of fuselages and the undercarriages are made in France, while the noses, tails and engines are built in Britain. Special low-loading trailers carry the parts to and fro across the channel. Six times a week a private jet speeds between Bristol and Toulouse, carrying engineers and executives to a day's work abroad. To help with the language problem, there's even a special Anglo-French aeronautical dictionary, in which "sonic boom" comes out, surprisingly, as "bang sonique."

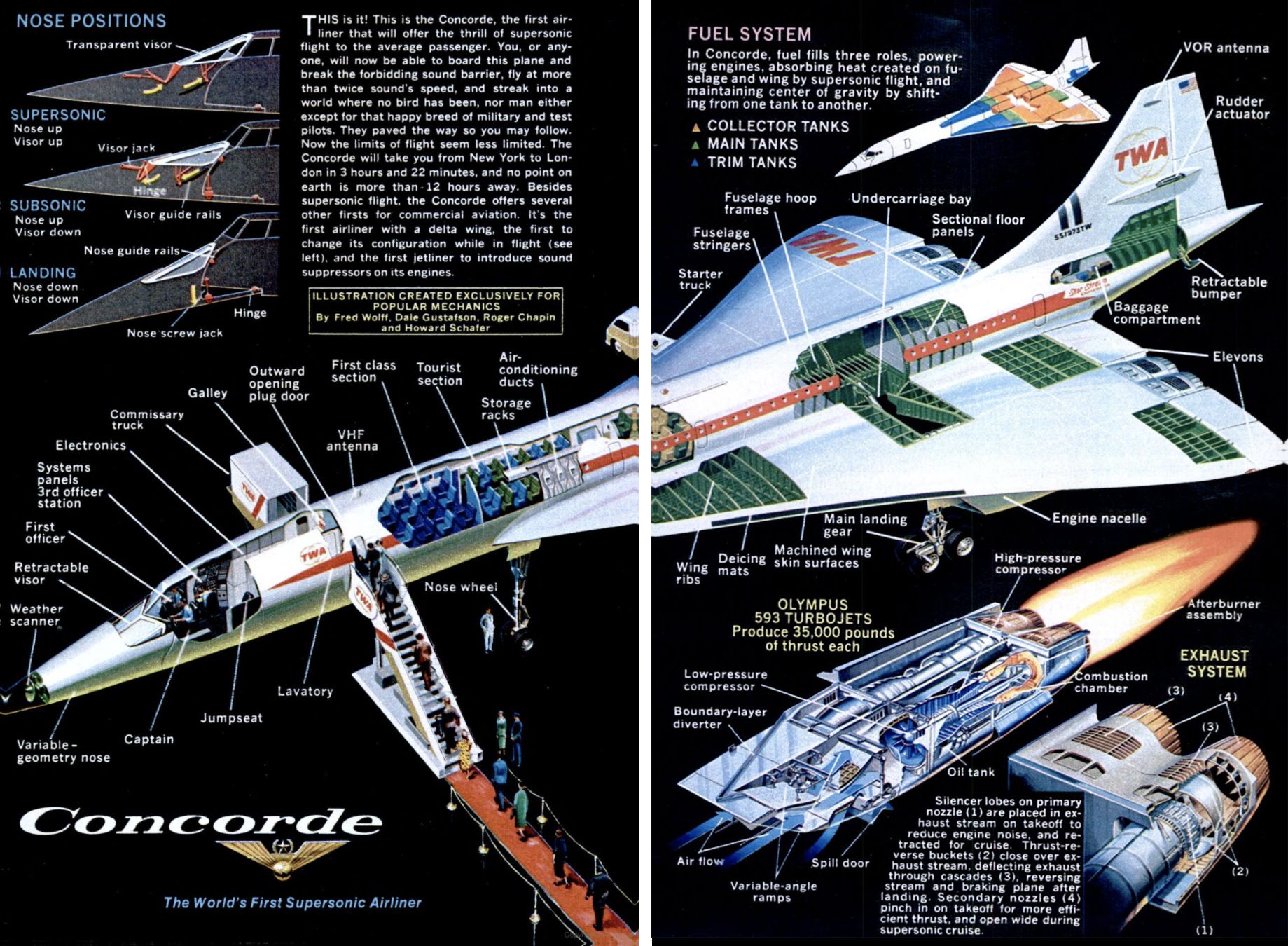

One hundred ninety-three feet long and only four seats and a corridor wide, the Concorde at rest is distinguished by a most unusual nose. Long and sharp like a cartoonist's mosquito, it appears to droop wildly toward the ground. For power, the Concorde will be whooshed upward and forward by four massive Olympus 593 turbojets, developed by Bristol Siddeley and the French firm, SNECMA. They pack, in all, some 140,000 pounds of thrust, or almost enough power for the huge ocean liner United States.

So much of this power is in reserve that the plane will take off from regular-length jet runways. The engines will get the aircraft to 40,000 feet in just 11 minutes, compared with half an hour for a subsonic jet. The normal cruising altitude of 60,000 feet will be reached in 500 miles and only 30 minutes.

The Concorde has none of the complications of"variable-geometry"wings; endless trials, calculations and wind tunnel tests showed designers how to build a slim, wineglass-shaped delta wing that would be efficient both below and above the speed of sound. So thin that they hardly look able to support the aircraft's 188-ton loaded weight, the 83-foot-span wings derive their lift from a highly intricate and sophisticated cambering and curvature.

The whole plane resembles that most elegant and basic aircraft, a schoolboy's paper dart.

Fuel Is Ballast and Heat Sink

Stowed within the wings—and under the fuselage-are the plane's 18 fuel tanks. The Concorde holds a maximum of 95 tons of kerosene, about 15 tons of which is in reserve, enough to meet 45 minutes of airborne "holding” and a 260-mile diversion. The fuel performs two other functions: Pumped to and from the front and rear tanks, it can adjust the plane's trim to cope with the different center of lift as speed changes, eliminating drag-producing trimming of control surfaces; it is also used as a "heat sink” to absorb surplus heat extracted from the rest of the plane.

Although it must be pressurized to keep it from boiling at high altitudes, the increased temperature of the fuel actually makes it more efficient.

The Concorde will gladden the hearts of record buffs. It's the first civil plane designed to fly faster than sound, or to have a droop nose or delta wing; the most completely automated; the fastest; the most expensive to date; and, say British Aircraft Corp. and Sud-Aviation who built it, the safest.

Automation and the computer have played a bigger part in the Concorde than in any other plane. The whole construction program was worked out by an American management aid called PERT (Program Evaluation and Review Technique). Much of the mechanical work is controlled by magnetically taped instructions to the multitude of power tools. During engine testing, the French and English test stations and the associated government research institutions were all wired to one computer link. Urgent results could thus be swapped-with complete accuracy-20 times faster than by telephone.

The Concorde is a riot of new and ingenious inventions, many of which, as spin-offs, may bring benefit soon to the man in the street. Take automatic chart display (ACD), for instance. In the center of the dashboard, an illuminated map shows the plane's course and position, and the surrounding countryside. As the plane moves or turns, the computer-controlled map shifts with it, always leaving the plane's position dead in the center. At the flick of a switch, the map—it's really a mini-TV screen—blows up to double scale. One tiny cassette holds 8,000 2,000-mile routes, any of which can be exposed at will. It is not hard to imagine the ACD—and its associated computerette—becoming a splendid "optional extra" in the vacationer's family car.

The Concorde may be the most "computerized” plane ever built. It reaches over 200 mph on the runway alone, and in the air the three-man crew would have little time to work out the hundred-and-one things that affect course, altitude, and speed. One computer collates current information about weather, fuel consumption, payload, noise regulations and course, and then recommends the correct setting. If, for example, one of the engines lost some power, the computer would adjust instantly to the new conditions. The pilot doesn't have to do anything.

"He could sit and do a crossword puzzle,” said a British Aircraft Corp. spokesman, “but he won't, of course.”

30 Minicomputers at the Controls

In all, the Concorde carries about 30 microcircuited computing devices, as small as a telephone or as big as a typewriter. (Their combined weight is only 70 pounds.) Computers take over the autopilot, including the autothrottle, the autostabilization (which makes the plane fly straight and level regardless of any roll or yaw), and the electric trim, which keeps the plane well balanced as conditions change, when fuel is used, at acceleration or deceleration, or even when three or four passengers walk down the aisle!

The computer systems are completely duplicated for safety, and are built to such exacting standards that not even the minutest fault is expected more often than every 600 hours.

"It's a belt-and-braces job,” explained the BAC spokesman, unconsciously hitching up his tweed trousers. Computer duplication is only one way that the Concorde is planned as the world's safest aircraft. The hydraulics system is triplicated—and even if all four engines should fail, their "windmilling" action would still be enough to keep the hydraulics going.

There are two parallel electrical circuits. The strict certificate-of-airworthiness conditions even lay down that the aircraft shall be flyable manually, if all electric and electronic signaling aids break down together. In the same way, new CA regulations dictate that cabin pressure shall be maintainable even with one of the four air systems out and with one cabin window smashed. To allow for the remote chance of solar flares producing an unacceptable amount of radiation, a special device gives enough warning for the pilot to glide down to a safe 50,000 feet.

All sorts of new problems arose in design. A cruising speed of Mach 2.2 (about 1,450 mph) would raise temperatures to 266° F. at the leading edge of the wings, a sizzling 307° Fahrenheit at the nose. It meant the use of a special heat-resistant aluminum alloy called Hiduminium RR 58 in Britain (AU 2 GN in France). They forsook heavier stainless steel and titanium planned for the American SST.

At subsonic speed, these surfaces could ice up, so they have to carry heaters, too. In the same way, the air conditioning system has to heat the interior at subsonic speeds and then cool it after Mach 1 is passed.

For engines, designers took the Olympus 320 meant for the now-defunct TSR 2, and worked from there. The basic principles, and the metallurgy, were proved to be fine. But this meant increasing the thrust from 30,000 lbs. (with afterburner) to 35,000 (without). For testing, they bolted it underneath a Vulcan bomber, flew it aloft, and then ran it under the surveillance of hundreds of gauges and four closed-circuit TV cameras.

On the ground, they catapulted four-pound chickens, fusillades of hailstones, and gallons of oil into the air intake. Olympus 593 digested them all without so much as a cough. To guard against "buzz"— a violent shockwave vibration caused by air entering the engine intake too fast—the 593 intake carries a complex system of ramps and spill doors to control the flow-all, of course, computer-controlled and linked to the autothrottle.

Hinged Noes Swings Down

In the first sketches, it became clear that the Concorde must have an unusually long nose—so long (20 feet in front of the pilot's controls) that visibility would be very poor for landing and takeoff. To let the pilot see where he was heading, designers hinged the whole of the nose (which also doubles as a radome) to drop 17.5° out of the way.

In flight, the nose is lifted level with the rest of the fuselage, and for supersonic flight, a long visor rises from the nose to meet the top of the windshield, making the whole plane impeccably sleek and aerodynamically trim. As a contrast to the futuristic origins of the rest of the Concorde, the nose cones are made of about 30 layers of huge, conical, fiberglass stocking knitted by the elderly craftswomen of an old-established Scottish hosiery firm.

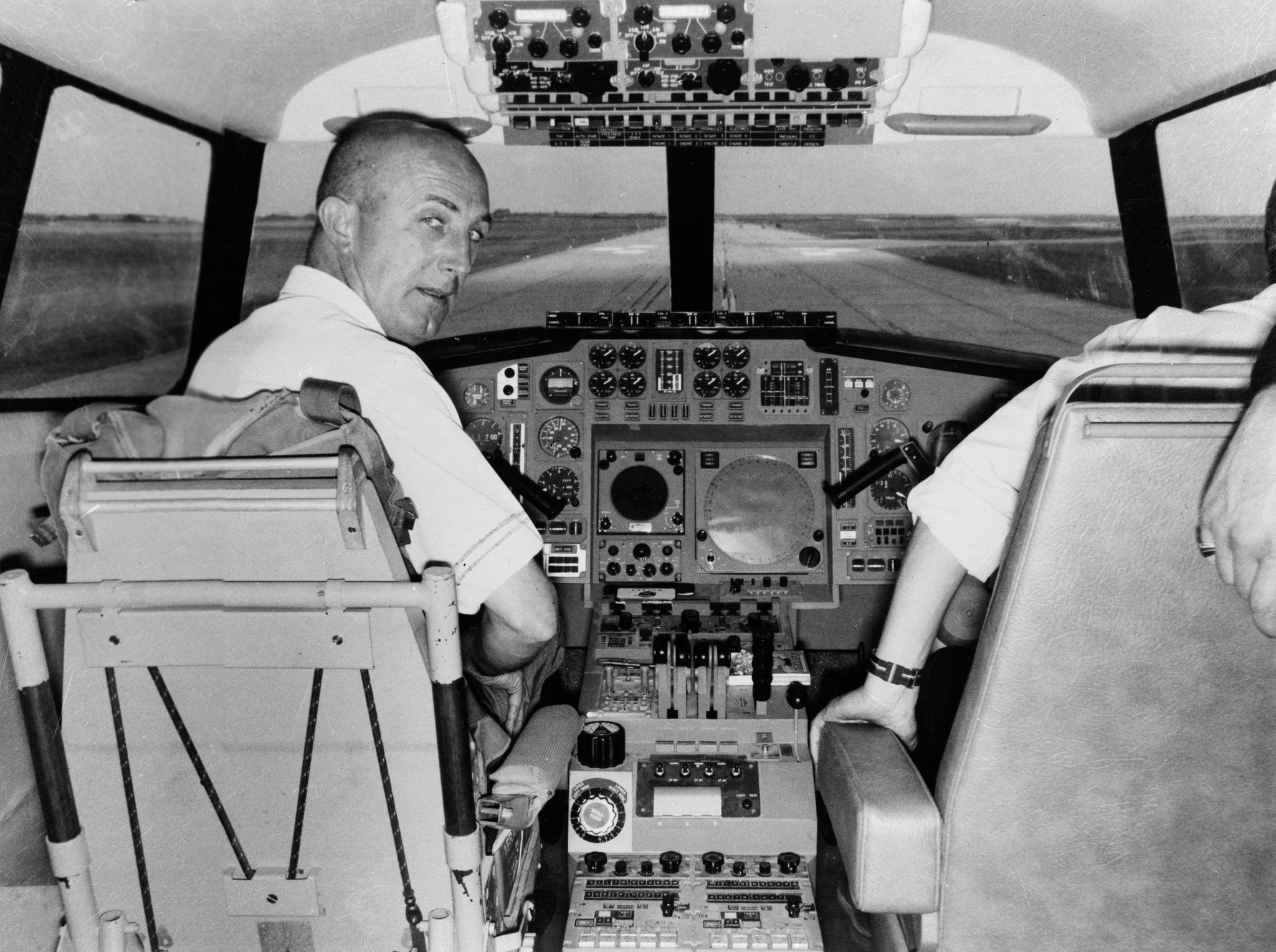

André Turcat, the prospective test pilot for prototype 001, has spent many hours at Toulouse, learning his new job in the $4 million flight simulator. Engineers out of sight test him to his extreme limits: They fix the dial readings to show that he is surrounded by fog, short of fuel, and bereft of electricity; sometimes, in playful mood, they pretend to set his undercarriage on fire.

Turcat can handle it all. This month, he will be handling it in earnest, in the air.

5000 Hours Just for Tests

Prototype 002 is scheduled to take off in late summer. Already work has started on 01 and 02, the preproduction models. They are already different from the prototypes: 12 feet longer, with engines 7 1/2 percent more powerful. These first four planes will never fly in service, but their job is vitally important. Before Concorde No. 1 is judged satisfactory for public service, 001, 002, 01, and 02, and 1 and 2 of the production aircraft must put in nearly 5000 flying hours.

Loaded with 12 tons of recording equipment, they will carry out rigorous testing and retesting for power and fuel consumption, range and speed, maneuvering and stability, efficient pressurization and resistance to metal fatigue, comfortable and quiet takeoff and smooth landing. They will be tried at high altitudes and low, in the freezing Arctic and at the scorching Equator, in gales and snow-every extreme condition that can be found.

In the meantime, confident representatives from 16 airlines have examined the full-scale wooden mock-up (which itself cost $350,000) and have deposited about $300,000 per plane for options on 74 Concordes. In the United States, Pan Am wants eight; American, Eastern, TWA and United, six each; Braniff and Continental, three each. To meet these and other anticipated demands, the two manufacturing companies plan to turn out Concordes at the fantastic rate of one a week once they get going.

The Supersonic Age is just round the corner. It will mean that the New Yorker can contemplate a day trip to London or Caracas; from Anyplace, U.S.A., to Anywhere, the World, will take at most 12 hours' flying.

Concorde's world has, by comparison with 19th-century travel, shrunk to the size of a county; the Atlantic to no more than a pond.