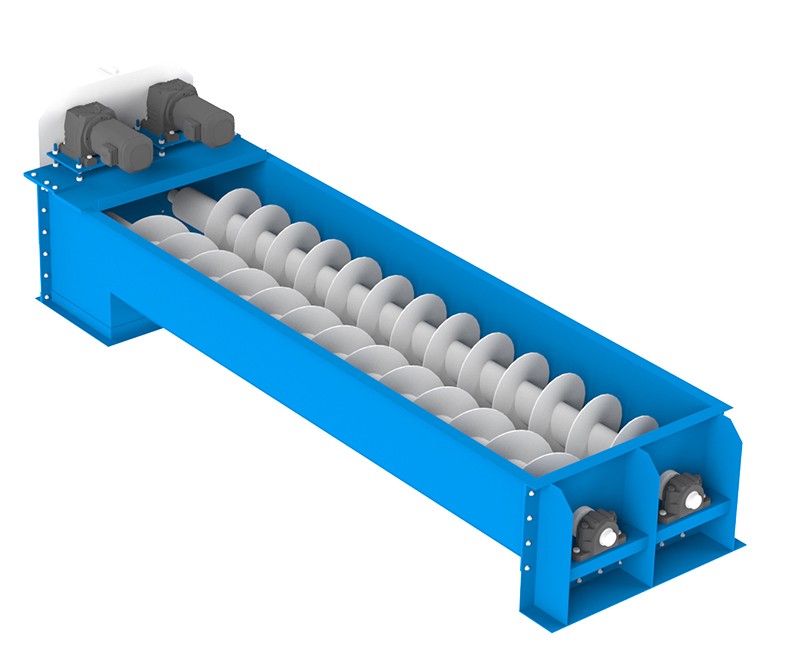

What is a Twin Screw Conveyor?

Twin screw conveyor is equipped with a solid spiral in two seamless steel pipes. It has mixing and stirring functions. It does not jam or block materials.

Twin screw conveyor is a combination of two blades, the rotation of the two screw shafts is opposite, and it has mixing and stirring operations, that is, while conveying materials, it can also carry out continuous stirring. This type of double-shaft screw conveyor It is used for conveying materials that have poor fluidity, large volume or size, and need to be stirred. They are generally used in industries such as food processing and construction processing.

What are the different types of Twin Screw Conveyor?

Twin-axis screw conveyor is a commonly used conveying equipment, which can be used in industrial fields such as cement, chemical industry, and metallurgy, as well as agricultural fields such as grain and oil. According to different functions and requirements, the twin-shaft screw conveyor has the following different types:

1. Ordinary double-shaft screw conveyor:mainly suitable for cement, chemical and other industrial fields, for conveying powdery or granular materials.

2. Crushing double-shaft screw conveyor: mainly used for crushing granular materials, which has a pair of special spiral blades, which can crush and mix materials.

3. Heating type double-shaft screw conveyor: mainly used in occasions where materials need to be heated. The spiral blades have built-in heating tubes to heat materials.

4. Cooling type double-shaft screw conveyor: It is mainly used in occasions where materials need to be cooled. The spiral blades have built-in cooling pipes to cool materials.

5. Lifting double-shaft screw conveyor: It is mainly used in occasions where materials need to be lifted up and down. It can perform automatic lifting operation to realize the integration of conveying and lifting.

Twin-axis screw conveyor is a commonly used conveying equipment, which can be used in industrial fields such as cement, chemical industry, and metallurgy, as well as agricultural fields such as grain and oil. According to different functions and requirements, the twin-shaft screw conveyor has the following different types:

1. Ordinary double-shaft screw conveyor: mainly suitable for cement, chemical and other industrial fields, for conveying powdery or granular materials.

2. Crushing double-shaft screw conveyor: mainly used for crushing granular materials, which has a pair of special spiral blades, which can crush and mix materials.

3. Heating type double-shaft screw conveyor: mainly used in occasions where materials need to be heated. The spiral blades have built-in heating tubes to heat materials.

4. Cooling type double-shaft screw conveyor: It is mainly used in occasions where materials need to be cooled. The spiral blades have built-in cooling pipes to cool materials.

5. Lifting double-shaft screw conveyor: It is mainly used in occasions where materials need to be lifted up and down. It can perform automatic lifting operation to realize the integration of conveying and lifting.

Benefits of Twin Screw Conveyor

1. The screw shaft and the hanging bearing, the head and the tail shaft are connected with the embedded tongue, and the installation and disassembly do not require axial movement, and the maintenance is convenient. Long mandrel, less hanging and fewer failure points.

2. Adopt variable diameter structure to increase the volume of the hoisting bearing, avoid the contact of the hoisting bearing with the material, and the life of the hoisting bearing can reach more than two years.

3. Each transmission part adopts the floating connection mode, and the hanging bearing is a universal struct.

https://www.dahanmachine.com/product-center/Tiwn-Screw-Conveyor.html

Screening conveying machinery Co., Ltd - designer

11mohttps://www.dahanmachine.com/product-center/Tiwn-Screw-Conveyor.html