Excessive Compressor Discharge Gas Temperature and Protection Measures

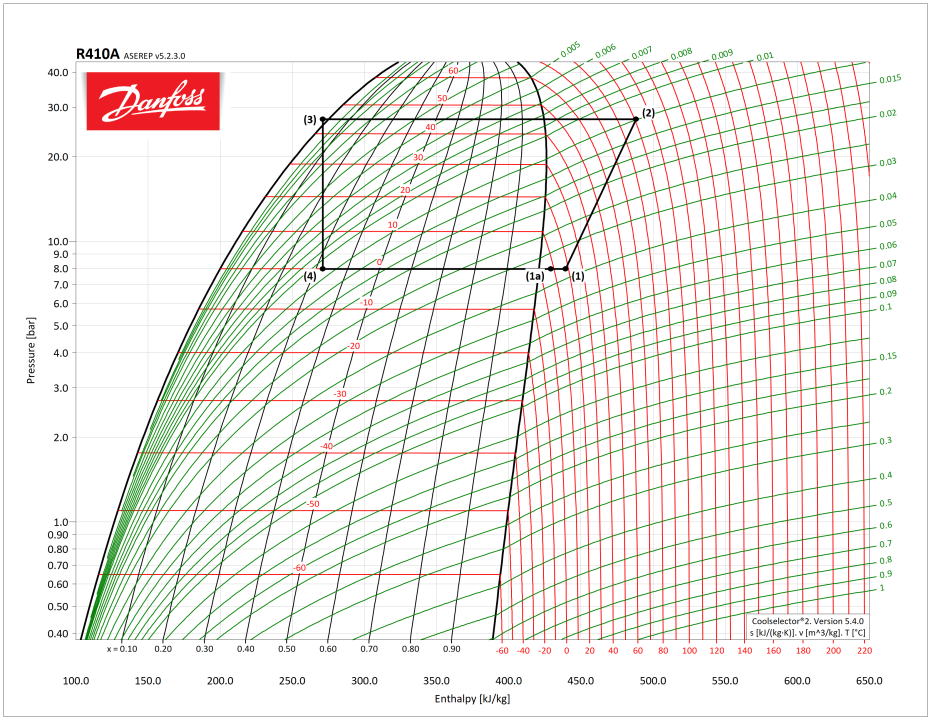

Excessive compressor discharge gas temperatures in refrigeration systems can have significant consequences. When the discharge gas temperature rises above 140°C due to factors such as inefficient superheat control, dirty heat exchangers or dryers, or an inefficient compressor electromotor, several issues can arise.

One of the main consequences is the "cooking" effect. When the discharge gas temperature becomes too high, the oil circulating with the refrigerant is subjected to elevated temperatures. This can result in the formation of carbon deposits on valves, oil channels, oil filters, and other components. The lubricating properties of the oil are reduced, leading to progressive wear and potential damage to the compressor.

Another concern is the stability of the refrigerant. Excessive discharge gas temperatures can affect the stability of the refrigerant, especially if there are contaminants present. This can lead to chemical reactions between the oil and the refrigerant, as well as compounds extracted from sealants and insulation materials. The outcome of these reactions can be the formation of contaminants, including acids, within the system.

To mitigate these consequences, it is crucial to implement discharge gas temperature protection. There are several benefits to having such protection in place.

Firstly, it helps protect the compressor from operating under conditions that could lead to damage or failure. By monitoring and limiting the discharge gas temperature, the protection system ensures that the compressor operates within safe working envelope, extending its lifespan and reducing the risk of costly repairs or replacements.

Secondly, discharge gas temperature protection improves the overall reliability of the system. The protection system detects and responds to abnormal operating conditions that could potentially cause damage to the compressor or other components. This helps maintain the system's performance and prevents unexpected breakdowns.

Safety is another significant aspect. High discharge gas temperatures can pose safety risks, such as oil breakdown or refrigerant instability or disjointing of brazing part in high pressure side. Discharge gas temperature protection helps mitigate these risks by preventing temperatures from reaching critical levels, ensuring the safe operation of the system.

Lastly, discharge gas temperature protection contributes to cost savings. By protecting the compressor and the system from damage, it helps avoid costly repairs, replacements, and system downtime. Additionally, it maintains optimal system performance and efficiency, leading to energy savings.

There are several ways to implement discharge gas temperature protection:

1. External temperature sensor: One common method is to install an external temperature sensor, such as an NTC (Negative Temperature Coefficient) or PT100 sensor, in the discharge line of the compressor. This sensor is connected to the system controller or drive, which monitors the temperature and triggers protective actions if the temperature exceeds the set limits.

2. Internal thermistor: Some compressors have an internal thermistor located in the discharge port of the fixed scroll. Excessive discharge gas temperature causes the electronic protector module to trip, providing internal protection for the compressor.

3. Thermostat: If a chiller or heat pump controller lacks enough analog inputs to monitor discharge temperature using sensor, it is possible to use thermostat or Temperature Switch as digital input or independent protection. . When the temperature exceeds the set point (125-130°C for R410A), the thermostat triggers a protective action, such as shutting down the compressor directly or send digital signal to main controller.

It's important to note that the specific method of discharge gas temperature protection may vary depending on the compressor model and manufacturer. It is recommended to refer to the manufacturer's guidelines and documentation for the appropriate protection methods for a particular compressor.

HVAC Consultant Engineer P.E. | Researcher

5mogood point. When temperatures surpass 140 °C the oil starts to disintegrate and is expected to mechanical damage in the refrigeration system.