Breaking & Making Capacity of a Circuit Breaker...Part 1

Okay this is going to be interesting a bit. I was once asked a question during a job interview the difference between Breaking capacity and Making capacity of a circuit breaker. The interviewer went on to ask which of the two is bigger. Unfortunately for me I could only define what the breaking capacity was but couldn’t tell the difference between the two. I replied that the breaking capacity was bigger. Huh?

Fortunately I did well enough in the other questions and I got the job. Yayy!!!

Great! you think right? Well with the benefit of hindsight and with what I know now, lets get this issue sorted out once and for all.

To start with, there are two types of Breaking and Making capacities. There is the normal and short circuit type. But for the purpose of this write-up we are only considering the Short circuit Breaking and Making capacities. Moving on I would be referring to the latter as Breaking and Making capacities.

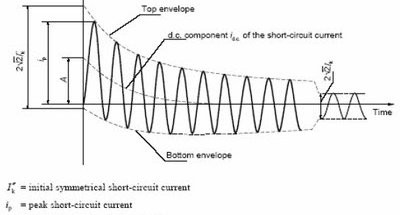

If you say that the breaking capacity is bigger than making capacity, there is a little truth in that. However in actual, Making capacity is more than breaking capacity. Making capacity correspond to the Peak values of short circuit current while Breaking capacity is the root mean square values. But for practical purposes and manufacturing, the big number is irrelevant. We are only interested in Breaking Capacity of a circuit breaker.

What about in economic terms? It’s the same. Breaking capacities discussion goes on in the marketplace and no one talks about Making capacity. Breaking capacity affects the price of a circuit breaker quite well. As they say in business parlance, Breaking capacities is the ‘deal breaker’.

Why?

Let’s dig deeper! Cool?

Breaking capacity is defined as the maximum short circuit current that a breaker can interrupt without damage to it. This is an important concept that underscores the principles of protection and coordination of protective devices.

Without understanding this, there is little or nothing to grapple when a fault arises. Breaking capacity is the ability of the switchgear to trip a fault under an abnormal condition.

Remember Switchgears, breakers inclusive, are generally for associated control, monitoring, regulation, and protection of electrical circuits from generation to transmission and distribution. In other words for us to select the appropriate switchgear, it is necessary to understand both normal and abnormal condition requirements. Under normal conditions we talk about operational currents, voltages, temperature etc. The abnormal conditions take us to the discussion on breaking capacity.

First byte of information – Protection CANNOT stop fault from occurring. It minimizes the effect to a few collaterals. The number goal is safety of human lives followed by the equipment, structure etc. The objective is to reduce to barest minimum the impact of the fault. A good protection system will in theory eliminate the effects of a fault. However a number of other factors can affect the reliability of your protection system. A classic example is environmental conditions like presence of impurities, dust particles, unwanted creatures et cetera.

Secondly we measure Breaking capacity in kiloamps (KA). This is so for convenient reasons since we are dealing with large currents here with magnitudes in tens of thousand amperes. Sometimes the Breaking capacity could be different at 220V and 415V for low voltage systems. Breaking capacity is either of ultimate breaking capacity type or service breaking capacity. Watch out for my next blog where I would explain the difference between Icu and Ics as per IEC standards.

Thirdly Breaking capacities for circuit breakers are standardized. They come in ratings such as 3KA, 6KA, 10KA, 15KA, 20KA, 25KA, 36KA, 50KA etc. In other to size your circuit breaker KA rating correctly, the expected fault level or fault current must be determined through calculations. The calculations are usually based on several assumptions, which in the end ensures that the calculated value is greater than the actual. This is a safe design mode.

Lets do a pause while we try to understand the points. We will come back to more explanation on my next post.

As with all my write-ups, the aim is to draw a parallel between the technology and daily applications. “Go-no go” decisions are made daily on projects usually based on cost-benefit analysis. I can tell you that a lot of cost-benefits are in Breaking capacities. Understanding how to coordinate protection with short circuit protection devices (SCPD) cannot be overemphasized for a safe and cost effective solution. Energy sustainability can only mean one thing – the best cost of safe energy for now and future needs.

Electrical Power Engineer

7yNice one.very explanatory and concise.

Pastor & Entrepreneur

7yspot on!!!