Non-Asbestos Gasket Materials

Non-Asbestos Gasket Materials

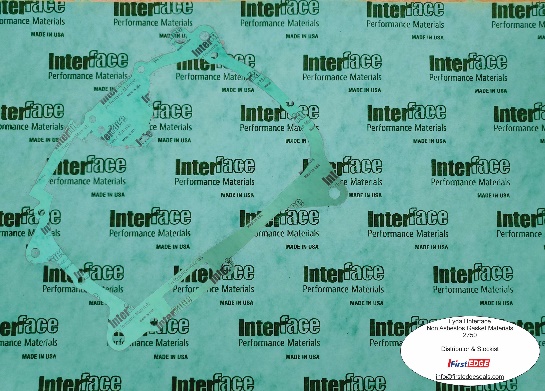

First EDGE Marketing are the Authorised Distributor of Lydall / Interface Non Asbestos Gasket Materials.

Click here to view Lydall Authorized Distributor Certificate

Link to LPMI Website: www.lydall.com/business-segments/performance-materials/

Link to Interface Website: www.interfacematerials.com/

Logos belong to their respective owners.

All Non Asbestos Gasket Material Grades are also available with ANTI-STICK COATINGS for easy release

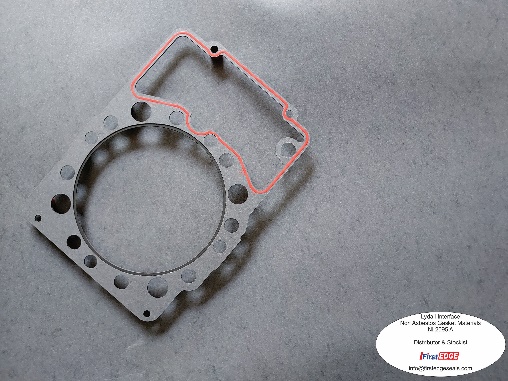

Grade: NI 2095 A

NI-2095A is a Cylinder Head Facing Material designed to deliver the performance required by worldwide cylinder head applications. It is a non-asbestos material with inorganic fillers encapsulated by Nitrile Butadiene Rubber, and is easy to combine on perforated metal core.

Click here to view Technical Specification Data Sheet.

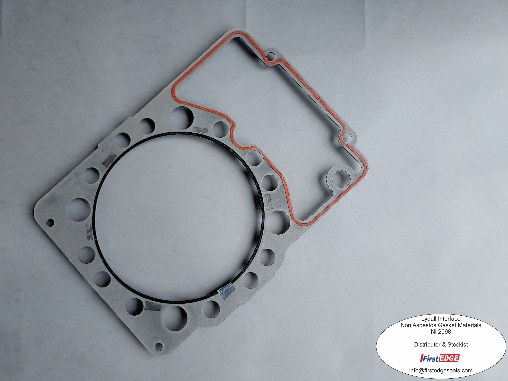

Grade: NI 2098

NI-2098 is a heavy-duty Cylinder Head Facing material that is used with both solid and perforated metal cores. It is a Non-Asbestos material with Nitrile Butadiene Rubber binder, and is compatible with most polymers used in bead printing processes.

Click here to view Technical Specification Data Sheet.

Grade: 217 SP

217SP is a medium density asbestos-free gasket material. It is an aramid fibre reinforced material with a blend of fillers & fibres bound with NBR-Latex. It is mainly used to seal against cold and warm oil, water and anti-freeze. It is intended for applications with maximum temperatures up to 250°C (480°F).

Click here to view Technical Specification Data Sheet.

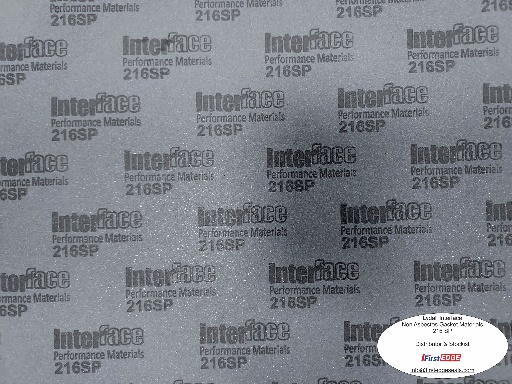

Grade: 216 SP

216SP is a medium density gasket material for use in sealing applications and is composed of a select blend of fillers & fibres with a NBR binder. It offers excellent saleability at low flange loads and good resistance to oil, fuel and transmission fluids. It is intended for applications with maximum temperatures up to 220°C (420°F).

Click here to view Technical Specification Data Sheet.

Grade: 2755

2755 is a general purpose aftermarket grade gasket material suited for air, coolant, and oil sealing applications. it has excellent compressibility, strength, and sealability characteristics, and is intended for applications with short duration maximum temperatures up to 190oc (375of).

Click here to view Technical Specification Data Sheet.

Grade: 2750

2750 is a general purpose aftermarket grade gasket material suited for air, coolant, and oil sealing applications. it has excellent compressibility, strength, and sealability characteristics, and is intended for applications with short duration maximum temperatures up to 190oc (375of).

Click here to view Technical Specification Data Sheet.

Grade: S 207

S-207 is a cellulose fiber gasket material with controlled-swell styrene butadiene rubber binder. It is a suitable replacement for asbestos fiber gasket materials, saturated papers, and is used in many oil and coolant applications in the aftermarket. It is intended for use in applications with short duration maximum temperatures up to 180°C (350°F).

Click here to view Technical Specification Data Sheet.

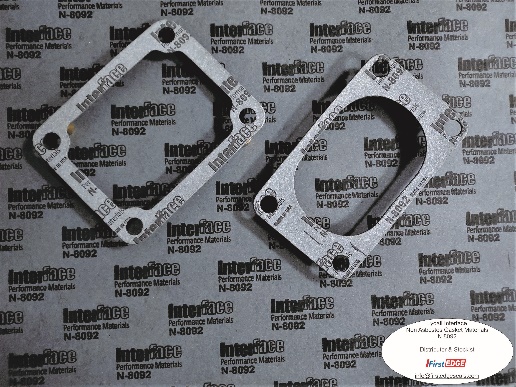

Grade: N 8092

N8092 gasket material is a Syntheseal® / Nonasbestos material made of reinforced cellulose fiber with a nitrile rubber binder. It has excellent crush resistance at high flange pressures, and excellent sealing properties with oil, fuel, and water. N-8092 gaskets are intended for applications with short duration maximum temperatures up to 180°C (350°F) and are commonly used in automotive, small engine, light duty compressor, and general purpose aftermarket applications.

Click here to view Technical Specification Data Sheet.

Grade: N 8094

N-8094 Syntheseal® / Nonasbestos Gasket Material is a medium density material that conforms well to irregular flange surfaces and has very good crush resistance at high flange pressures. It is intended for sealing oils, fuels, and water in applications with short duration maximum temperatures up to 180°C (350°F).

Click here to view Technical Specification Data Sheet.

Grade: TS 9013

TS-9013 is a controlled-swell material with latent cure styrene butadiene rubber binder and a blend of Aramid and cellulose fibers. It conforms well to irregular flange surfaces and is intended for water and oil applications with short duration maximum temperatures up to 290°C (550°F).

Click here to view Technical Specification Data Sheet.

Grade: N 8090

N-8090 has a latent cure nitrile butadiene rubber binder and reinforced cellulose fiber. it has excellent oil resistance, good sealing characteristics, and is intended for applications with short duration maximum temperatures up to 180°c (350°f). N-8090 has ul component recognition.

Click here to view Technical Specification Data Sheet.

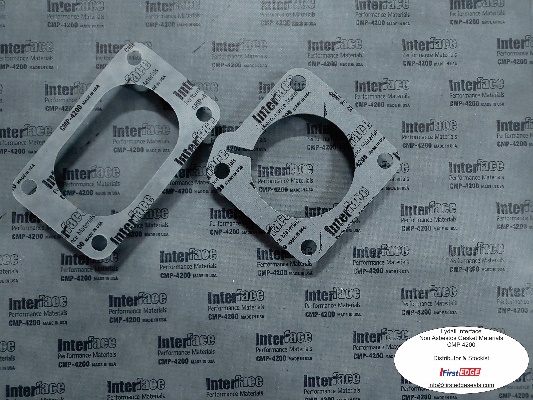

Grade: CMP 4200

CMP-4200 is a solvent-free, high performance compressed micropore gasket material. It was developed for steam, water, oil, and chemical resistance in original equipment and industrial applications. It has exceptional sealability, torque retention, crush and blowout resistance, and is intended for applications with short duration maximum temperatures up to 350°c (650°f).

Click here to view Technical Specification Data Sheet.

Grade: HFL 781

HFL-781 is a high density, controlled swell gasket material with styrene butadiene and natural rubber binders. it is used in heavy duty oil sealing applications such as diesel engine oil pans and front covers. it is intended for applications with short duration maximum temperatures up to 290°c (550°f). the following specification values are for 0.8mm (0.031”) gauge material.

Click here to view Technical Specification Data Sheet.

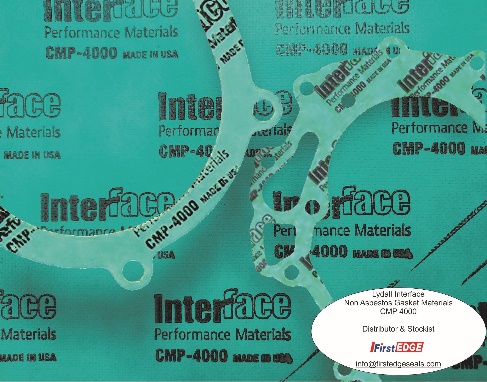

Grade: CMP 4000

CMP-4000 gasket material is a high performance, compressed micropore material that combines a unique synthetic fiber matrix with a fully cured nitrile butadiene rubber binder. Hydro-fused® cmp-4000 gaskets have excellent sealability and torque retention properties and are recommended for short duration maximum temperatures up to 350°c (650°f). Typical OEM and industrial applications for CMP-4000 gaskets include engine, transmission, hydraulics, pumps, valves, pipes, and compressors that operate from -40°c to 150°c and from 0 to 40 bar internal pressure. Applications outside this temperature and pressure range can be considered with proper validation testing.

Click here to view Technical Specification Data Sheet.

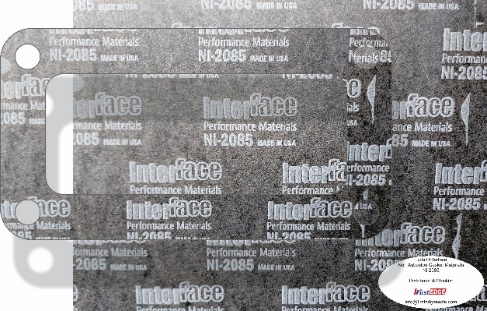

Grade: NI 2085

NI-2085 has a nitrile butadiene rubber binder for resistance to water, coolant, oil and fuel. It has excellent strength and sealability characteristics, and is intended for applications with short duration maximum temperatures up to 190°C (375°F). NI-2085 has UL component recognition.

Click here to view Technical Specification Data Sheet.

Grade: S 8091

S-8091 non-asbestos gasket material ideal for OEM and aftermarket coolant and oil applications, S-8091 is a controlled-swell non-asbestos gasket material. S-8091 syntheseal® is a latent cure styrene butadiene (SBR binder) bound product reinforced with cellulose fiber. intended for sealing oil, fuel, and low-pressure steam applications. specifications include a short duration maximum temperature up to 180°c (350°F). ASTM F-104

Click here to view Technical Specification Data Sheet.

Grade: TN 9004

TN-9004 Gasket Material TN-9004 gasket material is a heavy-duty, high density non asbestos material with a fully cured nitrile butadiene rubber binder. It has excellent resistance to fuel and oil and has good tensile strength. Thermo-Tork® TN-9004 gasket material is intended for applications with high flange pressures and short duration maximum temperatures up to 350°C (650°F). TN-9004 has a minimum tensile strength of 2500 psi in accordance with ASTM F152 standards.

Click here to view Technical Specification Data Sheet.

Grade: TS 9003

TS-9003 is a controlled-swell gasket material with a latent cure styrene butadiene rubber binder. It is an alternative to high-swell asbestos and nonasbestos compressed sheet materials. Its latent cure binder and heat resistant fibers give it good oil sealing characteristics at low flange pressure, and it conforms well to irregular flange surfaces. It is intended for applications with short duration maximum temperatures up to 350°C (650°F).

Click here to view Technical Specification Data Sheet.

Grade: MP 15

MP-15 Gasket Material MP-15 Pro-Formance® / MicroPore® Nonasbestos Gasket Material is designed for heavy-duty applications including compressors, diesel engines, and others. It has excellent low flange pressure sealability and bolt torque retention. It is intended for applications with short duration maximum temperatures up to 205°C (400°F).

Click here to view Technical Specification Data Sheet.

Grade: TN 9001

TN-9001 is a heavy-duty latent cure material with nitrile binder. It has excellent oil resistance and is intended for applications with short duration maximum temperatures up to 400°c (750°f).

Click here to view Technical Specification Data Sheet.