All About Cylindrical Lenses

/Cylindrical Lenses: An Overview

cylindrical lenses are used to shape incoming beams. Source: https://www.laseroptik.com/en/substrates/stock-substrates/cylindrical-lenses-prisms

Cylindrical lenses are a type of optical lens that have a cylindrical shape and are used to correct or manipulate the shape of a light beam. Unlike spherical lenses, which have the same curvature in both the horizontal and vertical plane, cylindrical lenses have different curvatures in these two directions.

Cylindrical lenses operate on the principle of refraction, where light is bent as it passes through the lens. The curvature of the lens surface causes the light to bend in a specific direction, causing the image to be distorted in one axis. This effect can be used to either stretch or compress the image in the direction perpendicular to the axis of the lens.

Applications of Cylindrical Lenses

Cylindrical lenses are widely used in a variety of applications, including:

Image projection systems

Image projection systems often require a high level of image quality, as well as accurate and uniform light distribution. Cylindrical lenses are commonly used in these systems to correct distortion in one axis and improve the overall quality of the projected image.

In an image projection system, light from a light source is passed through a cylindrical lens, which manipulates the light in a specific direction. The light is then projected onto a screen, where it forms a clear and sharp image. The cylindrical lens is used to stretch or compress the image in the direction perpendicular to its axis, correcting the distortion in one axis and producing a clearer, more uniform image.

For example, in overhead projectors, cylindrical lenses are used to correct the distortion that occurs when a light beam passes through a curved transparency. The cylindrical lens compensates for this distortion, ensuring that the projected image is uniform and free of artifacts.

Cylindrical lenses play a crucial role in image projection systems by providing a means of correcting distortion in one axis and improving the overall quality of the projected image. They are widely used in a range of applications, from overhead projectors to slide projectors, and provide a cost-effective and efficient solution for improving the quality of projected images.

Barcode scanning systems

Barcode scanning systems are widely used to capture and decode barcode information. Cylindrical lenses are often used in these systems to provide improved image quality and resolution, making it easier to accurately capture barcode information.

In a barcode scanning system, a cylindrical lens is placed in front of an imaging sensor, such as a CCD or CMOS sensor. The lens manipulates the light in a specific direction, correcting the distortion in one axis and improving the overall quality of the captured image. This allows the barcode scanning system to accurately capture and decode the barcode information, even if the barcode is distorted or angled.

For example, in a retail store, a barcode scanning system can use a cylindrical lens to scan barcodes on products for price and inventory purposes. The lens corrects any distortion in the barcode image, ensuring that the barcode information is accurately captured and decoded.

In another example, in a warehouse setting, a barcode scanning system with a cylindrical lens can be used to scan barcodes on packages and pallets. The lens corrects the distortion that may occur as the barcode passes through the scanning system, providing a clearer and more accurate representation of the barcode information.

Industrial inspection systems

Industrial inspection systems are used to inspect various components and products for defects, flaws, or other imperfections. Cylindrical lenses are often used in these systems to provide improved image quality and resolution, making it easier to detect and analyze defects.

In an industrial inspection system, a cylindrical lens is placed in front of an imaging sensor, such as a CCD or CMOS sensor. The lens manipulates the light in a specific direction, correcting the distortion in one axis and improving the overall quality of the captured image.

For example, in a metal rolling mill, cylindrical lenses can be used to inspect metal strips for cracks and other defects. The cylindrical lens is used to correct the distortion that occurs as the metal strip passes through the inspection system, providing a clearer and more accurate representation of the strip's surface.

In another example, cylindrical lenses can be used in a quality control system for plastic molding. The lens can correct the distortion that occurs as the molded parts pass through the inspection system, making it easier to detect and analyze surface defects, such as cracks, voids, and other imperfections.

Medical imaging systems

Medical imaging systems are used to visualize internal structures and organs in the body for diagnostic and therapeutic purposes. Cylindrical lenses are often used in these systems to improve image quality and resolution, making it easier to accurately diagnose and treat medical conditions.

In a medical imaging system, a cylindrical lens can be placed in front of an imaging sensor, such as a CCD or CMOS sensor. The lens manipulates the light in a specific direction, correcting the distortion in one axis and improving the overall quality of the captured image. This allows the medical imaging system to accurately capture and display the internal structures and organs being imaged.

For example, in endoscopy, cylindrical lenses can be used to provide a clearer and more detailed image of the digestive tract. The lens corrects any distortion that may occur as the endoscope moves through the digestive tract, providing a clearer and more accurate representation of the internal structures and organs.

In another example, in mammography, cylindrical lenses can be used to improve the quality and resolution of images of the breast. The lens corrects any distortion that may occur as the imaging sensor captures the image of the breast, providing a clearer and more accurate representation of the internal structures and tissues.

Types of Cylindrical Lenses

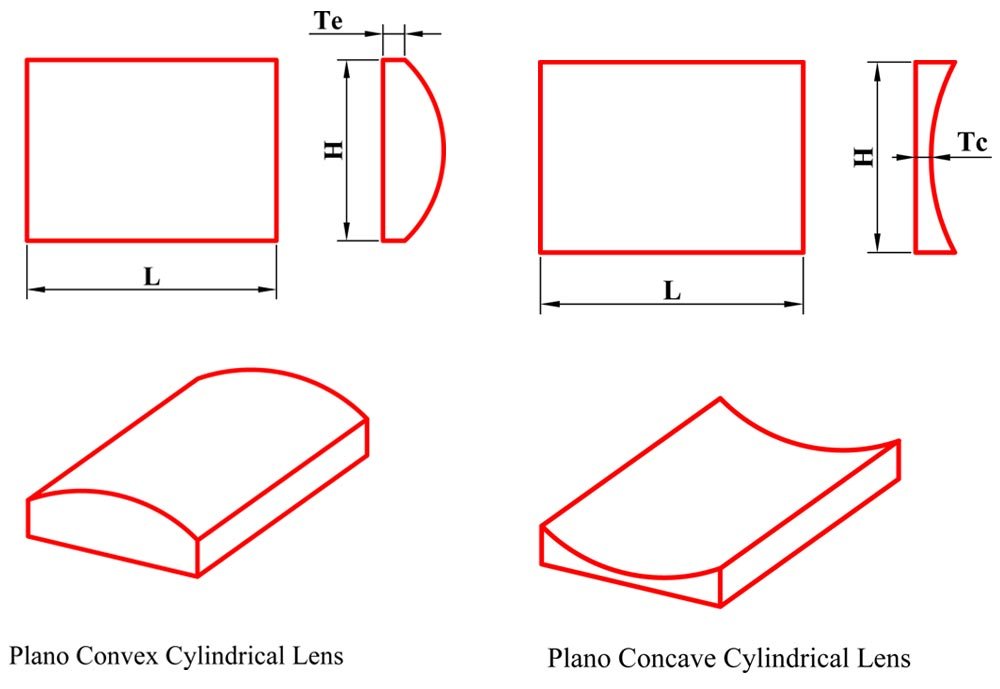

There are two main types of cylindrical lenses: positive (convex) cylindrical lenses and negative (concave) cylindrical lenses.

Positive (Convex) Cylindrical Lenses

Positive cylindrical lenses have a curved surface that bulges outward. They are used to magnify an object in one axis while having little effect on the other axis. Positive cylindrical lenses are commonly used in applications where a line of light needs to be stretched or expanded in one direction, such as barcode scanning systems and optical fibers.

Negative (Concave) Cylindrical Lenses

Negative cylindrical lenses have a curved surface that curves inward. They are used to reduce the size of an object in one axis while having little effect on the other axis. Negative cylindrical lenses are commonly used in applications where a line of light needs to be compressed or reduced in one direction, such as industrial inspection systems and laser scanning systems.

Breakdown of convex and concave cylindrical lenses. Source: https://www.altechna.com/products/positive-cylindrical-lenses/

Materials and Fabrication

The fabrication process of cylindrical lenses involves a series of steps to create the desired shape and surface finish. The following are the general steps involved in the fabrication process:

Blocking: The starting material is cut into a cylindrical shape, also known as a "block", that is slightly larger than the desired lens.

Grinding: The block is ground to the desired curvature and surface finish using a grinding wheel or other mechanical means.

Polishing: The surface is polished to the desired surface finish using abrasive materials and polishing tools, such as polishing cloth or pads.

Coating: If needed, an anti-reflective coating or other optical coating can be applied to improve the transmission and performance of the lens.

Inspection: The lens is inspected to ensure that it meets the desired specifications and performance standards.

The fabrication process of cylindrical lenses can be complex and time-consuming, and requires specialized equipment and expertise. However, the resulting lenses provide high accuracy and performance, making them ideal for a range of applications.

The choice of material depends on the specific requirements of the application, such as the wavelength of light used, the temperature and environmental conditions, and the required accuracy and durability. Cylindrical lenses can be made from a variety of materials, including:

Glass (e.g. BK7, Fused Silica, Sapphire)

Plastic (e.g. Acrylic, PMMA)

Polycarbonate

CR-39 (a type of resin)

Quartz

Infrared materials (e.g. ZnSe, Ge)

The choice of material depends on the specific application and requirements such as transmission, refractive index, abbe number, thermal stability, hardness, etc.

an example of a znse plano-concave cylindrical lens. what a mouthful, eh?

Advantages of Cylindrical Lenses

Light manipulation: Cylindrical lenses are designed to manipulate light in one axis, making them ideal for applications where a line of light needs to be stretched or compressed in one direction.

Improved image quality: By correcting or manipulating the light in one axis, cylindrical lenses can improve the quality and resolution of images, making them ideal for imaging systems, such as medical imaging or industrial inspection.

Cost-effective solution: Cylindrical lenses are a cost-effective solution for improving image quality in many applications, as they are simple and compact, and can be easily incorporated into existing systems.

Durability: Cylindrical lenses are typically made from durable materials, such as optical glass or plastic, and can withstand harsh environments and temperatures, making them ideal for industrial and medical applications.

Limitations of Cylindrical Lenses

Limited application: Cylindrical lenses are limited in their ability to manipulate light in two dimensions, and may not be suitable for applications where a more complex light manipulation is required.

Limited correction: While cylindrical lenses can correct or manipulate light in one axis, they may not be able to fully correct distortion in both axes, and may not be suitable for applications where high accuracy is required.

Complex fabrication: The fabrication process for cylindrical lenses can be complex and time-consuming, requiring specialized equipment and expertise, which can add to the cost of the lens.

Sensitivity to alignment: Cylindrical lenses can be sensitive to alignment, and must be positioned and mounted precisely in order to achieve the desired performance.

Cylindrical lenses have advantages such as cost-effectiveness, durability, and improved image quality, but also have limitations such as limited application, limited correction, and sensitivity to alignment. The choice of lens depends on the specific requirements of the application and the desired performance standards.

Conclusion

Cylindrical lenses are an important type of optical component that have a wide range of applications in various industries and fields. By combining precise fabrication techniques, high-quality materials, and advanced optical design, cylindrical lenses can be used to achieve precise and accurate light manipulation, making them a critical component in many modern optical systems.

As always, if you have any questions or custom designs, please reach out to us at info@firebirdoptics.com.

Here’s to your success!

Firebird Optics