ROAD GRADERS WITH GPS ARE A MUST HAVE FOR YOUR HEAVY EQUIPMENT FLEET

Dozers are arguably the coolest piece of heavy equipment out there; however, we can make a strong case for the road grader. Long gone are the days of graders being pulled by horses and tractors! The power and versatility of a modern-day road grader are two of the top reasons we consider it to compete with the dozer for being badass.

Road Grader on job site

About the Road Grader

Commonly known as road graders, motor graders, or blades, a grader is a necessary machine if you're in the construction or farming businesses. Unlike dozers and scrapers, used for rough grading, motor graders are used for fine grading. Their primary purpose is to prepare a flat and wide surface. These surfaces could be roads, highways, or even foundations for large buildings. With typically three axles, steering wheels in the front followed by the grading blade, then a cab and engine atop tandem rear axles, it can grade a large area. If equipped with GPS, it will grade with a millimeter level of precision and save you hours of staking manpower.

There are two types of frames for graders: rigid and articulated. Rigid frames are more traditional as they are built with two wheels in the front and two in the back and hinges attached to the blade. Articulated graders allow frame articulation between the front and rear axles, each with steering wheels attached to them. Articulation is essential when working in areas requiring a smaller turning radius because both wheels can pivot more easily than a rigid framed grader.

Motor graders come in various sizes (small, medium, large) and can adjust the height, blade angles, and tilt. They also allow for reverse grading, which comes in handy. Today's graders also have a variety of optional attachments that can go onto the rear, such as a ripper, a scarifier, or a compactor which gives it unquestionable advantages over other machines on job sites. This versatility isn't cheap upfront, but over time it pays for itself because it will allow bidding on larger, more complex jobs that others might not be equipped to handle. Motor graders can even be used for snow removal!

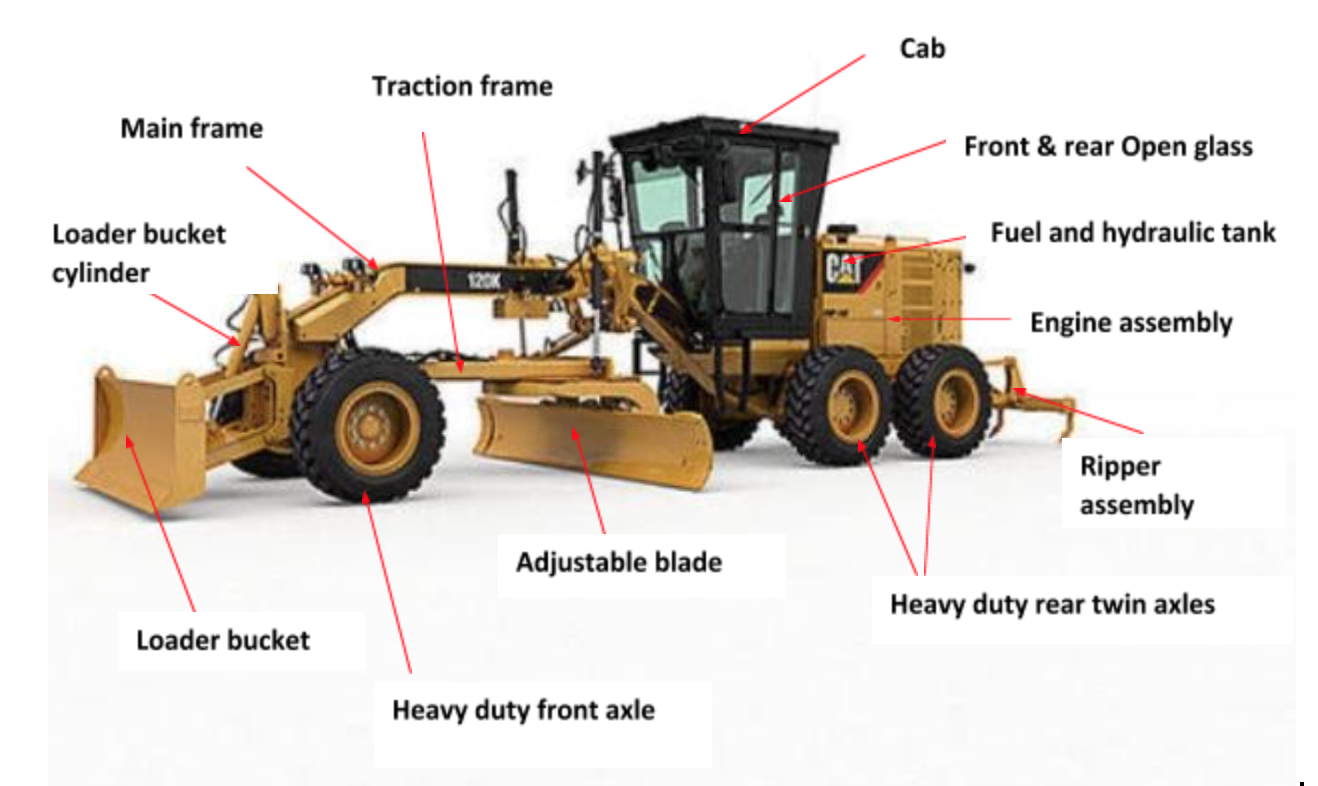

Components of a road grader

Improvements in Job Site Safety

Safety is automatically improved on job sites that use GPS motor graders because fewer people are walking around with stakes; therefore, there is less chance that someone will get struck by the grader. Many safety protocols must be followed on job sites to lessen the possibility of an accident.

GPS-enabled Graders Are the Way to Go

Getting back to why graders of today are far superior to the original versions from the 1920s is the extreme accuracy that results from graders equipped with GPS technology. It requires setting up a total station on a known control point. The communication between the grader's GPS, the 360-degree prism on the pole, and the radio frequency deliver the position to the grader. Skilled operators can get through grading a site faster and with little to no assistance from other crew members – goodbye string lines. GPS coupled with 3D models gives the operator real-time access to the information on a digital screen inside the cab. They can see things like elevations and full site maps so they can stay on course and reduce the number of passes, saving material, time, and ultimately money. GPS-enabled graders are 300% more accurate than non-GPS-enabled ones (read that sentence again)!

There's no doubt about it; motor graders are the preferred go-to machinery for fine grading. Their multi-purpose, convertibility, and functionality allow contractors to bid and efficiently complete different types of projects. Give ECI a call so we can get you the linework and 3D models you need to load into your grader. Don't waste time figuring out another way because a GPS-enabled grader coupled with our precisely drawn models will give you the best and most efficient project outcomes.