Contents

What Are Brake Caliper Pistons?

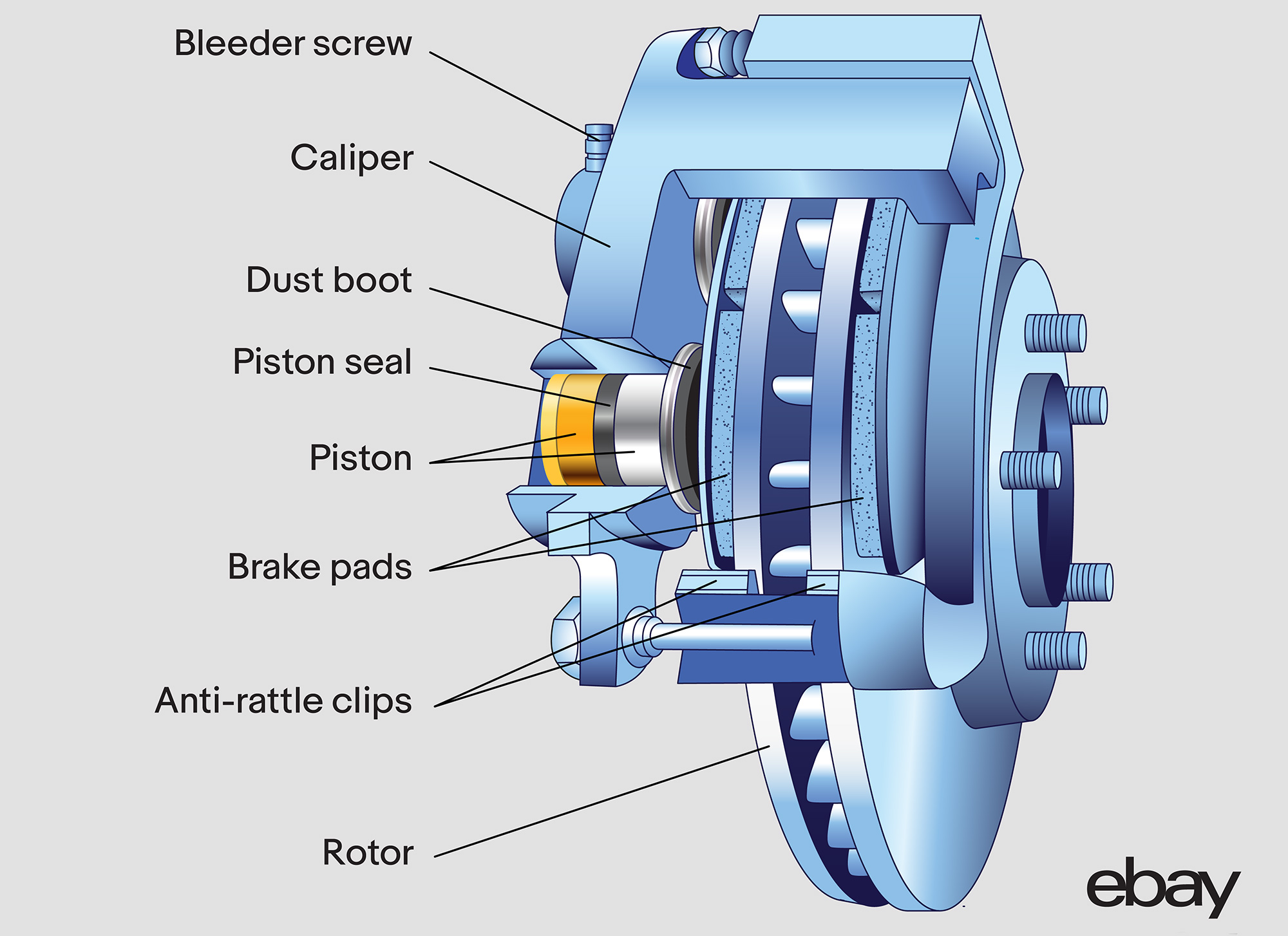

Brake pistons in the calipers ensure that the pads contact the discs to slow down the vehicle. When you apply pressure to the brake pedal, fluid comes out of the master cylinder and travels down the hoses and lines. It gets to the brake calipers, forcing the pistons to push the pads into the discs.

As you take your foot off the pedal, the pistons and pads retract, returning to an uncompressed state. If the pistons stick, the usual cause is swelling or corrosion. There can also be trouble with a brake fluid leak, preventing the pistons from moving. Otherwise, damaged piston seals are to blame.

Pistons are located in floating and fixed brake calipers.

- Floating calipers – Usually contain one or two large pistons on the inner side of the rotor.

- Fixed calipers – Small-diameter pistons are found on both sides of the rotor, offering additional braking force. This design typically has four to six pistons per caliper.

Brake caliper pistons are also made from varying materials.

- Plastic (phenolic) – A lightweight design that doesn’t conduct heat, used in heavy braking situations, such as in motorsports.

- Steel – This metal is strong but can corrode.

- Aluminum – Lightweight design allows excessive heat, leading to brake fade. It also can corrode.

Read more about brake caliper positions.

Automakers design brake systems to work with a particular piston material and brake pad. The brake pad shim, friction material, and piston are all engineered specifically to work together. The only way to replace the original steel caliper piston with phenolic or vice versa is to use a different brake kit. In most cases, this doesn’t make sense.

Tools Needed to Compress Brake Calipers

A professional brake caliper tool makes compression easier. This tool pushes in the brake piston so you can replace the pads. However, not everyone carries these tools with them. If you find yourself in a jam and need to compress the brake piston, you may not have time to wait for the right tools.

Here are a few common tools.

C-clamp

- C-clamp. Position your C-clamp over the caliper. You can use wood to prevent damage to the piston surface. While you turn the screw on the C-clamp, the pressure on the piston increases so it can be compressed.

- Channel locks. Channel locks work similarly to the C-clamp. Place the channel locks with one end behind the caliper and the other on the pad. The brake pad and caliper are between the grips. Squeeze the channel locks together and compress the piston.

- Screwdriver. If you put a screwdriver in the caliper window and pry on the piston, you may be able to push it in.

Keep in mind that when using ordinary tools, you can damage the caliper or piston.

Aside from the tool to compress the pistons, you will need other supplies. Because the piston is found on the brakes, you must remove the wheel first. This requires a floor jack, jack stands, and a lug nut wrench.

How to Compress Brake Caliper Pistons

The method of compressing brake caliper pistons varies depending on whether you work with the front or back.

How to Compress Front Brake Caliper Pistons

With a dedicated caliper piston tool, you can prevent injuries and make the job go faster. Here are the simple steps to follow.

Disc brake caliper wind back tool kit

- Lift your vehicle and place it on jack stands.

- Remove the front wheels.

- Take off the upper bolt that holds the caliper to the hanger.

- Pry the caliper from the hanger until you see the piston.

- Put a towel around the open reservoir cap to keep fluid from spilling on nearby components.

- Choose the appropriate rewind tool from the caliper kit.

- Attach the circular plate to your tool and tighten or loosen it to fit the caliper.

- Turn the lever so it is snug with the caliper.

- Turn the handle to compress the piston. It should get easier to turn after you get it started.

With the piston fully retracted, you can fit the new brake pads in.

How to Compress the Rear Brake Caliper Piston Without a Tool

If your car has rear disc brakes, it has self-adjusting pistons. These pistons move with the parking brake and are screwed in and out, making it impossible to compress them with a clamp-style tool.

Instead, these calipers must be turned. You could damage the rear caliper pistons if you attempt to compress them.

With channel locks or vice grips, you could twist the piston clockwise. As the piston turns inward, it will eventually be lower than the seal, indicating you should be able to change the brake pads.

Reasons Caliper Piston Won’t Retract

In a perfect world, the caliper piston would retract easily, and you could complete the brake job quickly. Yet, you may be unable to retract the caliper piston for a few reasons.

- Corrosion. Rust and corrosion are the most probable causes. Rust is most common if the car was parked for an extended time.

- Worn boot or seals. The rubber can keep the piston from moving as the seals deteriorate. Water also enters the piston when the boots or seals are torn, leading to an increased chance of corrosion.

- Incorrect wind-back procedure. Human error can also be to blame. If you don’t follow directions, the caliper may not compress.

Remember that the instructions for rear and front caliper compression are different.

Cost to Replace Brake Calipers

You can spend less than $20 to rebuild the caliper yourself. However, you must have substantial knowledge to rebuild it properly. On the other hand, rebuilt calipers for around $50 to $75 are available for many models. (With this cost, you’ll likely need to pay a core charge that will be refunded when you return the used caliper.)

These costs depend heavily on the type of vehicle you drive. Luxury cars and heavy-duty trucks have larger and more complex braking systems. Additionally, sports cars can include up to six pistons per caliper, making them more expensive. There’s also the material factor. If you buy steel calipers, the price will be lower, or you can choose more expensive billet aluminum for better performance.

If sticky brake calipers are a concern and you aren’t sure how to deal with the problem, it’s best to visit a professional mechanic. While you will pay more to have them installed professionally, driving when the brake calipers are stuck is unsafe.

Shop now for brake calipers