Do you have purchase plan to order flexible cable but need to know where to start? We are here to help! We will explain everything you need about flexible cables, including their different types and applications. We can assist you if you are a new buyer or have experience with them.

Flexible cable is essential in many industries because they are strong and easily bend. Flexible wires are critical for powering and connecting various electronic devices and machines. We provide in-depth technical details, enabling you to gain expertise in this field.

What is flexible cable?

Flexible cable, also known as a flex cable or flexible conductor, is an electrical cable designed to provide flexibility and durability in drag chain systems or applications requiring frequent bending, twisting, or movement. As we can see from the definition of flexible cable, they are distinguished by their ability to withstand a high number of flexing cycles without compromising their performance, in other words, maintaining electrical conductivity and structural integrity. This remarkable pliability and adaptability make flexible wire ideal for a wide range of applications.

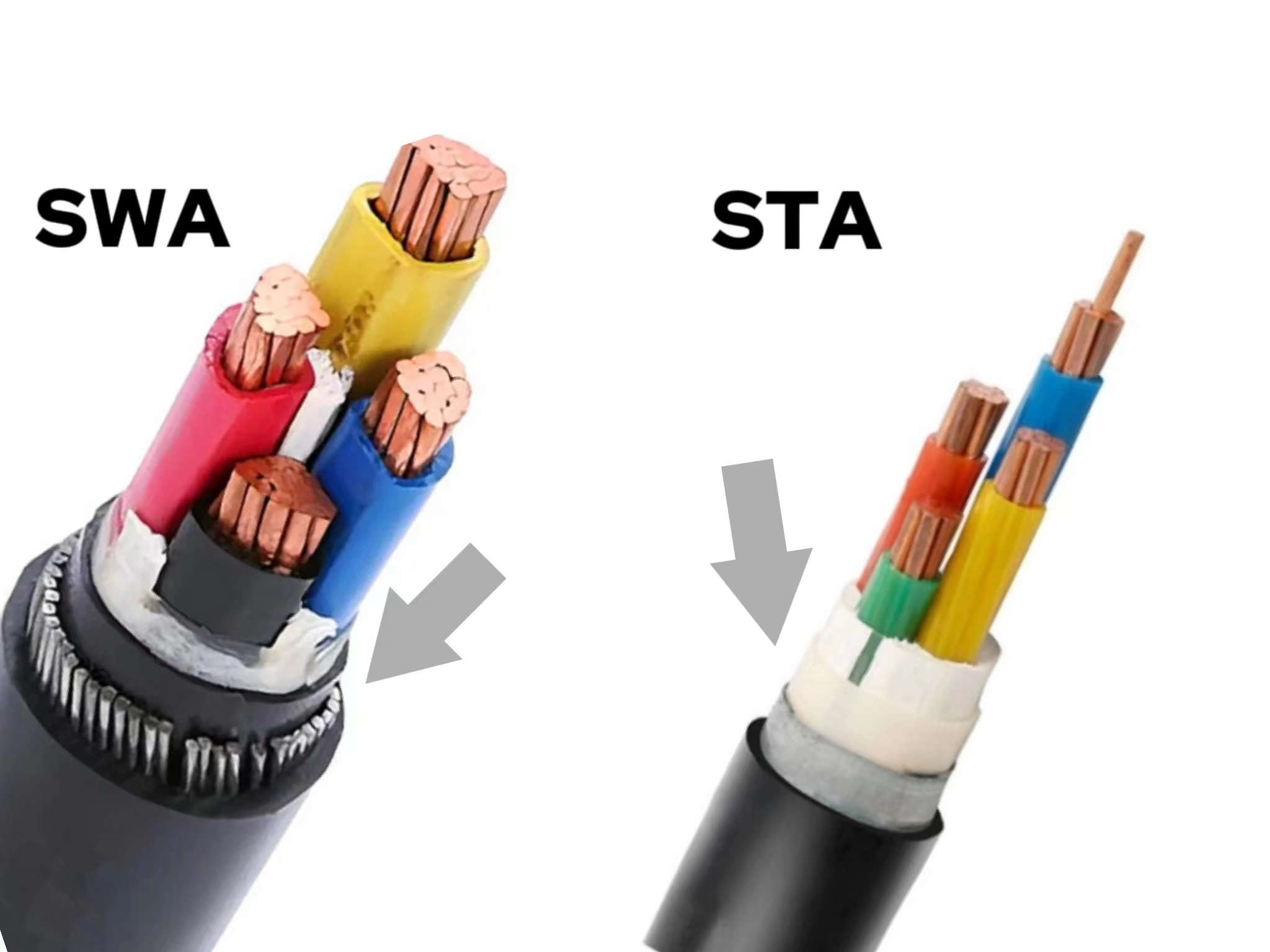

Flexible cable is crafted with stranded copper conductors instead of solid ones; each is individually insulated with PVC, rubber, or silicone to prevent electrical leakage and short circuits; and to maintain the cable’s shape and prevent conductor tangling, fillers, and separators are incorporated. The entire structure is enclosed with stretch-resistant PVC sheath, making flex cable resistant to chemicals, moisture, and abrasion. Common configurations come in flexible cable single-core, flexible cable 2 core, 6mm flex cable, and 3 core flexible cable. And Flexible armored cable is also a popular option in outdoor or underground applications. Moreover, the conductor may be color-coded to facilitate installation and identification.

It is due to the above characteristics that flexible cable wire has various uses in different industries. From daily home applications to heavy-dust industry applications, they are everywhere.

What are the flexible cables used for?

The application range of flex cables is very wide, covering almost every industry and field, and is preferred for power tools, control systems, data communication, and more. Here’s a breakdown of specific applications for flexible cable:

- Industrial machinery: In industrial automation systems, flexible electrical wires are used to supply power and transmit control signals and data; they connect sensors, motors, and components requiring movement, ensuring seamless operation and automation in various dynamic and demanding environments, from conveyor systems to mechanical assembly lines.

- Automotive Industry: in vehicles, flexible cable can be used for various purposes, such as connecting sensors, controlling engine, lighting, and communicating between electronic components, where they need to withstand the vibrations and movement associated with driving.

- Home Appliances: Flexible cables can be used as power cords for various home appliances, including refrigerators, washing machines, dryers, and vacuum cleaners, connecting the appliance to the electrical outlet and supplying the power needed for operation.

- Power Tools: Besides powering the power tools like drills, saws, and grinders, flex cables connect the control switch or trigger of power tools to the internal motor and other components. When the user activates the switch, the flexible conductor transmits the signal to start, stop, or adjust the tool’s operation.

- Portable Electronics: In portable devices like smartphones, laptops, and tablets, the high-flex cable connects components within the device to accommodate the folding and bending required for these compact designs.

- Medical Devices: Flexible cable connects sensors, imaging devices, and other control units to diagnostic and monitoring equipment in medical facilities, and is critical to patient diagnosis, treatment, and monitoring.

- Stage and Entertainment Lighting: Flexible cables are commonly used in stage and entertainment lighting setups. They can be easily routed through lighting trusses and fixtures, allowing for dynamic and flexible stage designs.

- Audio and Video Equipment: Flexible cables are vital in audio and video gear for connections between microphones, instruments, headphones, cameras, speakers, and more. They also provide the necessary flexibility for mobility and positioning while transmitting audio and video signals.

- Renewable Energy: Wind turbines and solar panels use rubber flexible cable to transmit power from the generators or panels to the electrical grid, in which cable needs to endure outdoor conditions and adapt to the motion of the wind turbine blades.

- Robotics: Robots and robotic arms often use flexible cable wires to transmit power and control signals to joints and actuators, and flexible electrical wire makes the movement and manipulation of robotic parts possible.

These applications highlight the versatility of flexible cable, and it is due to these many applications that flexible wire comes in many types.

What are the types of flexible cables?

The types of flex cables vary depending on their application, and each is designed to meet specific needs, but in general, flexible conduits are indispensable when mechanical protection, environmental conditions, safety regulations, or fire protection are required. Here are some common flexible cable types:

- Flexible Power Cable: These cables are designed to transmit electrical power. They connect power sources, such as generators or electrical outlets, to devices, machines, or equipment that require electrical power and are often used in indoor applications and for general-purpose power distribution.

- Flexible Control Cable: Used for transmitting control and low-voltage electrical signals; commonly found in automation systems, machinery, and instrumentation. Control cable may have multiple cores for carrying different signals.

- Flexible Flat Cable(FFC cable): These are thin, flat cables with a ribbon-like structure, and are typically used in applications where space is limited, such as laptops, printers, and other electronics. The same goes for fpc cable.

- Flexible Coaxial Cable: It is commonly used in television, radio, and networking applications. Designed for transmitting high-frequency signals, flexible coax cable is typically made of a central conductor surrounded by insulation, metallic shielding, and an outer insulating layer.

- HDMI Flexible Cable: designed to transmit high-definition audio and video signals between devices while providing flexibility and ease of installation, common applications including televisions, monitors, projectors, gaming consoles, Blu-ray players, and computers.

- Flexible Tray Cable: Used in cable trays, raceway, and conduit systems in power and control applications. Can be used indoors or outdoors depending on sheath material.

- Flexible Robotic Cable: used in robotic systems, industrial automation, and other applications where motion, flexibility, and reliability are paramount.

- Specialized Flexible Cords: These are a category of cables designed and engineered for specific, often demanding applications, with unique features and characteristics beyond those of standard flexible wires. For example, flexible Ethernet cable, ultra flex welding cable, mining cable, aerospace cable, and coiled cable.

It’s worth noticing that the choice of flexible cable type is just one piece of the puzzle, a vital aspect that significantly influences flexible cable’s functionality and performance is cable size.

Flexible Cable Size Chart

Flexible cable sizing is a critical step in ensuring safe and effective electrical connections and requires careful selection. To simplify this process, we provide a quick reference for single-core flexible conductor size, insulation thickness, weight, and current rating:

| Single core flexible cable size chart | ||||||

|---|---|---|---|---|---|---|

| Dimensions- number of cores x conductor cross-section (n*mm) | Cross-sectional area (mm²) | Outer diameter (mm) | Insulation thickness (mm) | Copper weight (KG/KM) | Cable weight (KG/KM) | Current rating (A) |

| 16*0.20 | 0.5 | 2.1-2.5 | 0.6 | 4.8 | 10 | 11 |

| 24*0.20 | 0.75 | 2.2-2.7 | 0.6 | 7.2 | 12 | 14 |

| 32*0.20 | 1 | 2.4-2.8 | 0.6 | 9.6 | 14 | 17 |

| 30*0.25 | 1.5 | 2.8-3.4 | 0.7 | 14.4 | 20 | 24 |

| 50*0.25 | 2.5 | 3.4-4.1 | 0.8 | 24 | 32 | 32 |

| 56*0.30 | 4 | 3.9-4.8 | 0.8 | 38.4 | 46 | 45 |

| 84*0.30 | 6 | 4.4-5.3 | 0.8 | 57.6 | 65 | 56 |

| 80*0.40 | 10 | 5.7-6.8 | 1 | 96 | 115 | 80 |

| 128*0.40 | 16 | 6.7-8.1 | 1 | 153.6 | 170 | 106 |

| 200*0.40 | 25 | 8.4-10.2 | 1.2 | 240 | 260 | 143 |

| 280*0.40 | 35 | 9.7-11.7 | 1.2 | 336 | 360 | 175 |

| 400*0.40 | 50 | 11.5-13.9 | 1.4 | 480 | 515 | 223 |

| 356*0.50 | 70 | 13.2-16.0 | 1.4 | 672 | 710 | 265 |

| 485*0.50 | 95 | 15.1-18.2 | 1.6 | 912 | 940 | 329 |

| 614*0.50 | 120 | 16.7-20.2 | 1.6 | 1152 | 1180 | 382 |

| 765*0.50 | 150 | 18.6-22.5 | 1.8 | 1440 | 1600 | 445 |

| 944*0.50 | 185 | 20.6-24.9 | 2 | 1776 | 2100 | 519 |

| 1225*0.50 | 240 | 23.5-28.4 | 2.2 | 2304 | 3015 | 609 |

The above table gives you a more intuitive understanding of the flexible cable size. And if you want to make a purchase, the following parts are to be noticed.

Some buyer advice for flexible cable

While flexible cable market is awash with options, each claiming to be the best fit for your needs, seeking the ideal solution is more challenging than it may seem. In addition to weighing the aforementioned types, applications, and specifications during the decision-making process, we offer some further guidance, as follows:

- Wire gauge: determines the maximum current-carrying capacity of a wire. , with thicker cables carrying more current. Make sure you choose the right cable gauge for your application to prevent overheating or voltage drops.

- Durability: Consider the cable’s durability in your intended environment. For harsh conditions, look for flexible cords with rugged jackets, resistance to chemicals, oil, UV radiation, and abrasion resistance. This ensures longevity and reliable performance.

- Flexibility: Determine how much flexibility the cable needs. If it will be subjected to frequent bending or flexing, select a cable designed for high flex life. Stranded conductors are generally more flexible than solid conductors.

- Length: Ensure the cable you choose is sufficiently long for your demands but not too much. Longer cables can cause problems with signal loss and noise, so keep the cable length within an appropriate range.

- Certifications and Standards: Ensure that the cable complies with applicable industry standards and certifications for security and performance. Examples include UL (Underwriters Laboratories), CE (Conformité Européene), and RoHS (Restriction of Hazardous Substances).

- Price vs. Quality: While budget is a consideration, prioritize quality over the lowest price. Avoid sacrificing quality for cost savings, especially in critical applications since cheap cables might not last long and could potentially lead to safety hazards and investing in higher-quality cables can reduce long-term maintenance and replacement costs.

- Warranty and Return Policy: Check if the cable comes with a warranty and understand the return policy of the seller in case the cable doesn’t meet your expectations or has defects. Normally, a longer warranty period can indicate the manufacturer’s confidence in their product’s quality

- Customization: If your application has unique requirements, inquire whether the supplier offers customization options for cable specifications, length, and connectors.

Flexible Cable Conclusion

Understanding the definitions, types, applications, sizes, and purchasing recommendations (offered by ZW Cable) for flexible cables allows you to make informed decisions for efficient and secure electrical connections. As a reliable flexible cable manufacturer, ZW provides tailored solutions and excellent customer support; best of all, they have high-quality copper flexible cables at affordable prices. ZW welcomes your inquiry.