Abstract

One important requirement for a polymeric material to be used as a membrane in fuel cells or water electrolyzers is its high ionic conductivity. In this research work the redeveloped conductometric titration was used to determine conductivity variation with the objective to improve the precision of the determination and reduce the time of operation. Results obtained by changing the experimental conditions of the techniques: reaction rate and conductometric titration, which are two related techniques, are presented. The reaction rate allows to know the chemical kinetics of the neutralization reaction between Nafion®117 membrane and a solution of sodium or potassium hydroxide, the order or pseudo-order reaction and the half-life period. This last parameter is used to carry out the conductometric titration which permits to determine the total acid capacity of this type of polymeric materials. The experimental conditions studied are: type and time of agitation and working temperature control. Good results were obtained in the techniques where the nitrogen bubble stirring was applied, throughout the determination. This procedure ensures a liquid medium with properties near isotropy, suitable for this analysis. The temperature controlled by a thermostat allows isolating the system of temperature variations and permits to compare the results between determinations. Time reduction was ~48 times lower, if 24 h is considered necessary to reach reaction equilibrium.

Similar content being viewed by others

Introduction

Fuel cells and water electrolyzers are energy converters. Water electrolyzers convert electrical energy into chemical energy, while fuel cells turn chemical into electrical energy. Polymer electrolyte membrane fuel cells gained public attention when an ionic exchange resin was used as electrolyte for a space application by General Electric in 1959 [1]. 1 year later, the same company, trying to overcome the disadvantages of alkaline water electrolyzers developed the concept of a new electrolyzer that used a solid polymer electrolyte instead of the liquid alkaline electrolyte [2].

Proton exchange membrane fuel cells have acquired importance for applications that require rapid start-up and quick response to load changes [3]. Proton exchange membranes are the key component of those types of devices and the most important requirements are: high proton conductivity, low electronic conductivity, good chemical stability and good thermal stability, low permeability to fuel and comburent, low electroosmotic drag coefficient, good mechanical properties and low cost [4].

To analyze the conductivity of polymeric materials that can be used as membrane in this type of devices, conductometric titration was redeveloped.

Conductometric titration is an analytical technique based on the mobility difference, that is, ions of a certain mobility are replaced by other ions that possess a different mobility. This technique presents advantages if it is compared with the acid–base or potentiometric titrations, when particular systems are studied. Those systems are the ones that generate products of considerable solubility or hydrolysis products at the equivalent point. Apart from that, the conductometric titration maintains its accuracy in relatively diluted as well as concentrated solutions. This technique can be applied to study colorless and color solutions. The measurement electrodes are the only feature which does not form part of the solution because they do not affect the system under study (the reaction) [5]. However, in the acid–base titration the indicator can interact with the system or produce contamination. The use of indicators adds another disadvantage since the wide range of pH that they present can influence in the value of the determination error [6].

The disadvantage that the conductometric titration presents is that the system under study does not have large concentrations of strange electrolytes, which can interfere with the reaction because, as a consequence, it would considerably reduce the results precision [5].

Originally, this technique required a complex process, so it was not widely used but, as technology improved, the devices used to measure conductivity were simplified and some researchers decided to apply it. The bibliography presented as follows tries to show different cases where the conductometric titration was applied over diverse types of polymeric materials or their monomers (such is the case in this research work) with the intention of obtaining particular information from them or their reactions. It is very important to observe the steps followed in each of the determinations proposal to analyze the time spent in the application of the technique and if any substance is incorporated which can alter the results of the determination. The examples presented are:

-

Waltz et al. used the conductometric titration to calculate the amount of amine end-group in nylon 66 (polyhexamethylene adipamide). The pre-treatment of the sample under study, consisted of dissolving the polymer using purified phenol and shaking the system. Then 95% ethanol and distilled water were added. After that, conductometric titration was carried out using, 0.1 N hydrochloric acid and slow stirring. As phenol was not a good solvent for the determination of the carboxyl end groups because after equivalent point, it reacts with the base, the benzyl alcohol is used instead. Even though the conductance found was lower than that expected for the solvent previously used (phenol–ethanol–water) and the cut point of the two straight lines was not so sharp, the results obtained by conductometric titration were in agreement with the ones obtained by titration using an indicator [7]. In this research work to analyze the amine and carboxyl end-group is necessary to dissolve the sample of polymer under study, which considerably increases the time needed for the determination. Another important statement presented, is to find the correct solvent or mixture of solvents that do not incorporate an error in the interpretation of the results obtained.

-

Erbil et al. determined the copolymer composition and monomer reactivity ratios by conductometric titration of acrylamide and itaconic acid. There, the pre-treatment consisted of dissolving 0.1 g of solid polymer with 30 mL of 0.1 N sodium chloride using a magnetic stirrer. 0.1 N sodium hydroxide was used as titrant. From established mixtures of homopolymers (of acrylamide and itaconic acid), the equivalent point was obtained and the data were used to construct a calibration curve that allowed estimating the acidic comonomer content and calculating the copolymer composition [8]. In this case, it is also necessary to dissolve the polymer to obtain the parameters above expressed by the inflection points of the titration curves, increasing the time needed to carry out the experiment and added ion species in the system.

-

Bochek et al. suggested the conductometric over the potentiometric titration to calculate the esterification degree of polygalacturonic acid. Usually, the procedure consists of determining the number of free carboxy groups, with phenolphthalein as indicator and with the same solution, obtains the number of esterified carboxy groups by back titration. This technique needs a pre-treatment to dissolve the pectin under study. The pectin was dissolved by wetting with ethanol and with the addition of distilled water heated at 40 °C. The system was stirred for 2 h. They emphasized that the color turn of the indicator occurs in a relatively wide range of pH so this fact can result in a considerable error in the determination. Their results showed that conductometric titration is the technique that offers more similar results to those published in the literature, if compared with the results obtained by potentiometric titration [6]. Two important conclusions can be remarked from this research work. The first one is the benefit of not using an indicator in the conductometric titration technique, so the error of this kind can be disregarded and the second one, which was related to the first one, is the advantages of implementing this technique over the potentiometric because it offers more accurate results.

-

dos Santos et al. presented two different methods to obtain the degree of deacetylation of the linear polyaminosaccharide, chitosan: CHN elemental analysis and conductometric titration. After a purification procedure the sample of chitosan was dissolved using 0.05 M HCl and it was stirred for 18 h at room temperature. Titration resulted in a secure and inexpensive method if compared with the equipment-dependent and more expensive CHN elemental analysis [9]. The time needed for purification is long and once again the use of HCl may incorporate ion species that can alter the reading of the results.

-

Okubo et al. applied conductometric titration to study the relative distribution of carboxyl groups in a polymer emulsion of styrene/butyl acrylate/methacrylic acid in serum, at surface and inside particle. All the samples were pre-treated and conductometric titration was carried out with 0.02 N potassium hydroxide, at room temperature. The pre-treatment of the sample takes around 9 h where it is necessary first, adjusting the pH to 2 by the addition of 0.2 M HCl and then stirring for 2 h. The resulting emulsion was ultra-centrifuged for 2 h with the purpose of separating the serum and polymer particles and then the polymer particles were redispersed in distilled deionized water. This process was repeated three times and the supernatants were collected in each step to measure carboxyl groups in serum [10]. The methodology used in this work although simple, required a long time to obtain good results and the necessity of incorporating HCl to adjust the pH, may alter the results of the determination as it was mentioned in the above examples where it was used.

In the investigation work carried out by Everett et al., it was suggested that when the conductometric titration was applied to surface characterization of polystyrene lattice, solids content had to be greater than 2% w/w. The reason to use that concentration or greater was that at lower concentrations the time needed to achieve the system equilibrium was extended. They established 36 h to finish a complete titration experiment [11]. In the same work, they explained the benefits of adding an electrolyte to the system. If this type of conductometric titration was carried out in the presence of equal parts of solid content and electrolyte (1:1), the time needed to complete the titration was reduced to about 8 h. To justify the variation of time between determinations (without and with the presence of electrolyte as potassium bromide), they suggested a slow conformational change during neutralization of the polymer chains carrying the acid groups. They exposed their concern about the results obtained by other researchers, who applied the conductometric titration in very short periods of time, less than 30 min, because they thought that those results did not correspond to true equilibrium [12]. This research work established two important facts. The first one is that researchers that used the conductometric titration technique previously, needed to study the kinetics reaction to know when the reaction analyzed reached equilibrium, under the experimental conditions that were established. The second important fact is to know the time needed for the reaction to reach equilibrium. The time data has to be taken into account to carry out the conductometric titration.

It is important to remark that in five out of six different investigation works mentioned above, where the conductometric titration was carried out, the sample had to be pre-treated, that is to say that it was necessary first, to dissolve the material under study to be able to apply the titration. So, as mentioned, this involves more time and the possibility to incorporate contaminants or ion species that can alter the results of the conductometric titration carried out. From the work of Everett et al., it is evident that it is very important to study the kinetics reaction before applying the technique and have the knowledge of the necessary time for the reaction to reach the equilibrium for the correct application or interpretation of the results obtained from the conductometric titration technique.

In general terms and conditions, the conductometric titration technique consists of the addition by burette of small and equal quantities of titrant to the system under study. The final system, solution to be titrated and the titrant, is agitated after every addition and then the conductivity is measured.

The registered conductivity is used to plot a graphical representation as a function of the volume of titrant added. This graphical representation consists of two straight lines that cut in the equivalent point [5, 13, 14].

In optimal conditions the error of the determination is 0.5%, so part of this paper deals with different modification in the technique to obtain more accurate results [5].

The aim of this research work is to look for the better conditions to put in practice the conductometric titrations of polymeric materials to determine the total acid capacity and the equivalent weight, without taking the reaction to an end in a complete way. The changes proposed are related to the way in which the system is agitated: with magnetic or bubble stirring; or the time during the agitation is applied to the system: along all the determination or only during a specific period of time. Another parameter analyzed is the possibility to set the temperature in which the experiment is carried out or not. All the parameter modifications have the purpose of reducing the time of the determination and the accuracy in the results obtained by the technique. So the parameter modifications that affect the results in the direction exposed above will be selected.

Materials and methods

Practical theoretical framework of conductometric titration

To present the system proposed in this investigation work, a sample of Nafion®117 perfluorosulfonic acid (PFSA) is immersed in 70 mL of distilled water. This represents the system to be titrated. Potassium or sodium hydroxides are used as titrant, so the reaction involved in this titration is a neutralization of a strong base with a perfluorosulfonic acid. The Nafion®117 membrane is the acid, the hydroxides are the bases. The chemical reaction is represented as follows:

where R is the copolymeric matrix of the membrane, M is the cation that in this case are sodium and potassium [15].

In a typical conductometric titration of strong acid with a strong base the conductivity first decreases because the hydrogen ion of the acid is exchanged by the cation of the base. The mobility of the hydrogen ions is the highest (349.6 cm2/Ω mol at 25 °C) so when the reaction occurs, those ions form part of the molecule of water which has a low dissociation constant. The conductivity measured is the conductivity of the cation. When the equivalent point is reached the conductivity starts to increase in proportion with the amount of base added. The reason for this result is the mobility of the hydroxide ions (199.1 cm2/Ω mol at 25 °C) [5, 13–16].

In the system under study, where a piece of Nafion®117 membrane was immersed, first conductivity stays low because the membrane exchange protons with the medium, due to the addition of the base, to form water. In that molecule the protons and hydroxide ions are not available as mobile ions so this is the reason for the conductivity to stay low. When the equivalent point is reached the conductivity starts to increase because the membrane does not have any more protons to exchange and the conductivity is the result of the hydroxide ions added in excess. The equivalent point in these types of materials represents its total acid capacity (TAC). So the conductometric titration allows knowing an important property of these polymeric materials as the total acid capacity and can be provided in a shorter period of time.

In general, to obtain that value, the polymeric material is exposed to an excess of sodium chloride to exchange all its protons and form hydrochloric acid. Then the hydrochloric acid is titrated with sodium hydroxide using methyl orange as indicator [17]. This technique could take around 24 h if the analyst wants to be sure that the membrane has exchanged all the protons and then, the extra time needed to carry out the titration. The conductometric titration can reduce the operation times to 30 min or less without the need for system equilibrium.

In a previous work having the purpose of knowing the reaction rate of the neutralization reaction, a sample of Nafion® 117 PFSA was immersed in a solution of 70 mL of distilled water and a specific amount of sodium or potassium hydroxide of known concentration. Once the membrane is immersed in that solution, the conductivity is registered every minute during an established period of time. Those results were used to plot a graphical representation of conductivity as a function of time and through this analysis it could be possible to determine the order or pseudo-order reaction. The neutralization reaction presents one as an order or pseudo-order reaction. From this previous work it can be concluded too, that for the reaction between a piece of Nafion® 117 PFSA and sodium hydroxide, 7-h period is approximately necessary to complete 99% of the reaction. Therefore, considering the neutralization reaction of these materials is not such a rapid reaction, the previous study of the kinetics and the conditions that can affect it becomes essential. These facts lead to the modification of the original conductometric titration technique to achieve the development of that technique in reasonable periods of time [18].

From the graphical representation of the first-order reaction the rate constant can be obtained and with this value, the half-life period [19, 20]. The half-life period is defined as the time needed for the reaction to complete half of the concentration of the reactants, and this is the time used as a parameter to carry out the conductometric titrations. This reduces the time needed to obtain the value of the total acid capacity to a considerable extent.

Reaction rate

The previous study of the reaction rate of the reaction used in the conductometric titration, allows knowing the chemical kinetics, the order or pseudo-order reaction and the half-life period. This latter parameter is very important in this particular determination because it allows reducing the time needed to perform the conductometric titration. As it was mentioned before, to attain the total acid capacity of polymeric material in specific determinations (different of conductometric titration) it is necessary to wait around 24 h to assure system equilibrium. The knowledge of the half-life periods allows developing the conductometric titration without reaching the system equilibrium and consequently reducing the operation times. As the reaction rate is affected by the modification of agitation and temperature, it is convenient to analyze case by case to see how it is influenced as the value of the half-life period too.

Reaction rate with magnetic stirrer

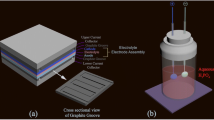

The technique to establish the reaction rate of the neutralization reaction consists of a Pyrex beaker where 70 mL of distilled water is added to the sample of membrane under study. The Pyrex beaker is dipped into a big water container, thermically insulated, which has achieved room temperature. This container was installed on top of a magnetic stirrer (Decalab S.R.L.; 2000 rpm; 280 °C) and the stirrer. Throughout the determination the system is kept stirred. Besides, inside the Pyrex beaker, the bench conductivity meter is added. That conductivity meter is a Eutech Instrument Pte. Ltd/Oakton Instrument CON 510. The meter was packaged with a two ring stainless steel Ultem-Body Conductivity/TDS electrode, which cell constant K = 1.0, with built in temperature sensor for automatic temperature compensation and an integral electrode holder. When the room temperature is reached in the Pyrex beaker, the magnetic stirrer is switched on and the amount of titrant needed to exchange all the counter ions of the membrane is added. The titrant is supplied through a burette (IVA, certificate number A-03819, serial number 005-02-08, tolerance ± 0.05 mL, uncertainty ± 0.03 mL, K = 2). The conductivity is measured every minute during long periods of time that can change between 1 and 5 h depending on the case. It will be named as reaction rate with magnetic stirrer.

Reaction rate with partial magnetic stirrer

In the second technique applied to determine the reaction rate inside the Pyrex beaker, 70 mL of distilled water is added together with the amount of titrant needed to exchange all the interchangeable ions added through a burette.

This system is stirred for 1 h to homogenize the solution with a magnetic stirrer. When that time goes by the Pyrex beaker is dipped into a thermostat (HAAKE C and F3 Fisons) for 1 h to reach the working temperature of 19.0 ± 0.1 °C. Then, when the Pyrex beaker is in place the bench conductivity meter is added and when the working conditions are reached, the sample of membrane is immersed in the solution (distilled water plus titrant) and the conductivity is measured every minute during an established period of time. This technique will be named as reaction rate with partial magnetic stirrer.

Reaction rate with bubble stirring

In the third technique designed inside the Pyrex beaker, 70 mL of distilled water is added together with the amount of titrant added through a burette. This system is stirred for 1 h to homogenize the solution with a magnetic stirrer. After that time, the Pyrex beaker is dipped into a thermostat for 1 h to reach the working temperature of 19.0 ± 0.1 °C. Then the bench conductivity meter is placed inside the Pyrex beaker with the stirring system that consists of a 2 mL plastic pipette that is connected by a hose to a tank of nitrogen. The flow of nitrogen is controlled by a flow meter (Cole-Palmer Mass Control System 0-500 SCCM, Display and LSPM w/DC-62 cable) at 0.229 g/min (standard cubic centimeter/minute N2 at 25 °C and 14.6696 PSIA). Finally the sample under study is added into the Pyrex beaker and every minute during an established period of time, the conductivity is measured. This determination is going to be named as reaction rate with bubble stirring.

In all the techniques the results obtained in the experiments are used to plot a graphical representation of the conductivity as a function of the time.

When the graphical representation of conductivity (κ) as a function of time was plotted, the experimental data obtained (experimental conductivity, κexp) was divided by the constant of the cell (Kcell), using Eq. (1):

The values plotted (rectified conductivity, κr) are the results of the application of this equation.

To obtain the value with the constant of the cell, a solution of potassium chloride was prepared. The concentration of that solution was chosen among those that could be found in the bibliography because the conductivity of those types of solutions was determined with accuracy at different temperatures. The expression that defines the constant of the cell (Kcell) is (2):

where R is the resistance of the measured solution. As the resistance is inverse to conductivity, replacing and rearranging the equation remains as (3):

where κbibl is the value of the conductivity found in the references. 0.7462 g of potassium chloride was dissolved in 1000 g of distilled water. 70 mL of that solution was added into a Pyrex beaker; the Pyrex beaker into a thermostat to reach the working temperature and then the conductivity meter was placed inside the beaker too. The working temperature selected was 18 °C and the experimental value obtained for the conductivity was 0.00135 S/cm2 and the value obtained in the bibliography was 0.00122 S/cm2. This result gives us a cell constant of 1.11 [18].

In a previous work, the reaction rate was determined and it was concluded that the order or pseudo-order kinetics for the neutralization reaction is 1. The graphical representation of the first-order kinetics is the natural logarithm of κ as a function of time and κ was obtained by (4)

where κ∞ is the last value of conductivity determined in the experiment.

Conductometric titrations

Conductometric titration with magnetic stirrer

In the same way the techniques of reaction rate change, the conductometric titration changes too.

In the first conductometric titration proposed, in a Pyrex beaker, 70 mL of distilled water is added with the sample of membrane. The Pyrex beaker is placed inside a big water container that is located over the magnetic stirrer. The stirrer is placed in the Pyrex beaker with the bench conductivity meter and when the room temperature is reached, the magnetic stirrer is switched on. After an established period of time a specific amount of titrant is added, through a burette, into the Pyrex beaker and the conductivity of the solution is measured and registered [15]. It will be named as conductometric titration with magnetic stirrer.

In the conductometric analysis, a graphical representation of conductivity as a function of volume of titrant added is plotted. The equation applied to the experimental conductivity (κexp) obtained in the assay is (5)

where κexp0 is the conductivity of the system (70 mL of distilled water and the sample of membrane) before the addition of titrant; F is the dilution correction factor. This factor is calculated by Eq. (6)

where V is the initial volume of the system and v is the volume of titrant added.

Conductometric titration with partial magnetic stirrer

In the second experiment the preparation of the Pyrex beaker is the same, but it is immersed in the thermostat with the bench conductivity meter. 1 h later, when the working temperature of 19.0 ± 0.1 °C is reached, a specific amount of titrant is added through a burette but the established time between additions is divided in two; the first portion is used to stir the system with the magnetic stirrer (outside the thermostat) and the second portion to reach the working temperature inside the thermostat [21]. This technique is named as conductometric titration with partial magnetic stirrer.

The data processing in this experimental part is the same as the one presented below (conductometric titration with magnetic stirrer). To plot the graphical representation of conductivity as a function of time, the conductivity used is the one that results from applying Eq. 1.

When the first-order kinetics was plotted to calculate the value of conductivity the equation used is 4, but in this case the κ∞ is the value of conductivity after 24 h.

Conductometric titration with bubble stirring

In the third conductometric titration, 70 mL of distilled water is added into the Pyrex beaker with the membrane. The beaker is placed inside the thermostat and after that the bench conductivity meter and the stirrer system are placed inside the beaker. The stirrer system consists of a 2 mL plastic pipette connected to a tank of nitrogen by a hose. The flow of nitrogen is controlled by a flow meter at 0.229 g/min. When all the elements are in the right place and the working temperature is reached, a specific amount of titrant is added through a burette, after certain periods of time, the conductivity is measured and registered. This technique will be named as conductometric titration with bubble stirring.

For the experiments carried out in this section, the data processing is the same as the ones exposed in the experiments of partial magnetic stirrer with temperature control.

These measurements allow plotting a graphical representation of the conductivity as a function of the volume of titrant added.

Results and discussion

Reaction rates

In the first technique, reaction rate with magnetic stirrer, where the temperature is controlled into a big water container, the limitation is that the temperature was limited to the room temperature, so this limitation did not allow comparing the results obtained in a determination, for example by duplication, because the temperature during the day can change or is not the same on the day when the experiment is repeated. As it is known, the mobility of the majority of ions, increases as temperature rises, in approximately, 2% for each degree [5].

In the second technique, reaction rate with partial magnetic stirrer, where a thermostat is used to establish a working temperature, but the agitation is only applied at the beginning of the determinations, two important limitations were found. The first values obtained had to be dismissed because the membrane takes some time to respond to the solution where it is immersed, so the fluctuation of the determinations can be seen. The second limitation found is that reaction rate is lower.

In the third technique, reaction rate with bubble stirring, where the thermostat is used and a bubble stirring is incorporated, the limitations of the previous techniques are improved. The thermostat allows working at the temperature chosen for the experiments avoiding the fluctuations between determinations and the stirring system favors the diffusion process between the membrane counter ions and the titrant ions used.

Figure 1 shows the results obtained in the study of the reaction rate of two solution of KOH where the time of agitation is different. Figure 1a is the result of stirring the solution throughout the determination with a magnetic stirrer, and Fig. 1b is the result of stirring the solution with a magnetic stirrer for only 1 h before the determination begins.

The magnetic stirrer seems to allow the reaction of neutralization to happen from the beginning of the determination to the end, without abrupt fluctuation in the values obtained along the experiment. The agitation only in the preparation step of the system (1 h) caused fluctuation in the determinations along all the experiment and a delay in the development of the reaction until the working rate for that experimental conditions, is reached. The agitation allows reactants to be more in contact and this benefits the reaction progress.

Figure 2 presents the results obtained for the behavior of two systems where a solution of NaOH is added but these two systems were stirred in two different ways. Figure 2a shows the results obtained using a magnetic stirrer and Fig. 2b using a bubble system.

The magnetic agitation in this case, seems to be insufficient to provide boundary conditions to study this type of system, if it is compared with the same system stirred by nitrogen bubbles.

Conductometric titrations

The conductometric titration, allows knowing the total acid capacity of the membrane under study as well as the equivalent weight. The total acid capacity can be achieved finding the cross-point of the two straight lines of the graphical representation of conductivity as a function of the volume of titrant added after every specific period of time.

Dupont in the specification sheet of the properties of Nafion® 117 PFSA membrane establishes the typical value of the total acid capacity between 0.95 and 1.01 meq/g (that can be expressed as 0.98 ± 0.03 meq/g). The technical sheet expresses that the value of this property is obtained by base titration to measure the equivalent sulfonic acid in the polymer [22].

The results of the conductometric titrations of samples of Nafion® 117 PFSA membrane are presented in Figs. 3, 4, 5 and 7.

The working conditions of samples of Fig. 3 are presented in Table 1.

Due to prolonged exposure of the membrane to the alkaline solution (24 h) it can be affirmed that the neutralization reaction is almost totally complete in both cases, making the process nearly independent of the agitation type. This fact is evidenced in the low conductivity values obtained in the first straight line of the two graphical representations (Fig. 3a, b). The values of the calculated TAC are 0.924 and 0.917 meq/g, respectively.

The values obtained in both determinations are very close to each other, and the absolute errors that they presented with respect to the value specified by Dupont are very similar too.

Figure 4 shows the behavior of the Nafion® 117 membrane under the conductometric titration using magnetic and bubble stirring. The linear equations of the two straight lines are presented too. The total acid capacity for the first system (with magnetic agitation) is 1.14 meq/g, and for the system with nitrogen bubbles agitation is 1.07 meq/g. It seems that the system under bubble agitation presents a more similar value to that presented by Dupont, and the absolute errors verified those results presenting a lower value. Working conditions are presented in Table 2.

It can be observed too, that the reaction is not completed due to the reaction times established in the determinations and this fact is evident in the first straight line that is not totally horizontal with the coordinate axis. It presents an upward slope. This is the result of the mobilities of the hydroxide ions and cations that do not react with the membrane yet. However, TAC can be accurately calculated.

Figure 5 presents the results of two samples where one of them was stirred throughout the determination (Fig. 5a) and the other was stirred half of the time between determinations, in this particular case 14 min of the 29 min wait. During the remaining 15 min, the system was immersed again into the thermostat to reach the working temperature. Table 3 establishes the working conditions of those systems and the absolute errors.

The systems had the same behavior of the ones presented in the previous figure (Fig. 4). The straight line that corresponds to the results of the neutralization reaction presents an upward slope. The values obtained for the TAC are 1.108 and 0.96 meq/g, respectively. The use of the thermostat improves the value of the determination, although only a little, approaching the value presented in the literature. The absolute error showed that although the values obtain are smaller, the absence of a thermostat could increase it to double.

Finally, in Fig. 6, the results of the kinetics study of the neutralization reaction of a sample of Nafion® membrane with a solution of potassium hydroxide are presented. Figure 6a is the graphical representation of the data recorded and in Fig. 6b; the mathematical treatment of these experimental values is shown, taking into account the first-order kinetics. From the graph, the slope that allows us to calculate the half-life period of 30 min is obtained.

Figure 7 shows the results of the first straight line (which represents the conductivity of the system after the neutralization reaction) of the conductometric titrations, of different samples of Nafion® 117 membrane, where the only variable that was changed is the time used between the aggregates of titrant. It should also be noted that the determinations are carried out using a thermostat and were stirred throughout the experiment by nitrogen bubbles. Working conditions and absolute errors are presented in Table 4.

The times between aggregates were: the half-life period (30 min) calculated in previous experiment, a reduced half-life period (23 min) and then study the system after 24 h between determinations. The results obtained for the TAC are: 1.07; 0.967 and 0.9173 meq/g, respectively. All values are close to those proposed in the literature. This allows claiming that the technique can be used for the determination of this property reducing waiting times in these systems.

The absolute errors by its fluctuation evidenced that an in-depth study of the bubble system is needed to guarantee the isotropic characteristic of the liquid medium. Two relevant aspects will be the position of bubbler and the flow of nitrogen with the objective to rich medium characteristic and accuracy in the results.

The application of this technique in the determination of the total acid capacity presents two improvements with respect to the bibliography listed in the introduction. The first one is that the sample under study does not have the necessity to be dissolved. This reduces the possibility of contaminating the system with the incorporation of ionic species that can alter the results reading, for example by their interaction with the reaction which is taking place. The second one is that it reduces the time needed to carry out the complete determination, because as it was shown the pre-treatment takes at least 2 h, depending on the case. So the technique offers the direct determination of the property without pre-treatment of the sample and the previous analysis of the suitable solvent for the material.

The titration analysis to obtain the total acid capacity of weak acid cation exchanger, for example has two pre-treatments: one to convert the material to the standard acid form and the other exchanges all the protons to the media with the purpose of making a back titration with thymolphthalein [17]. This determination can take a long period of time if the analyst wants to assure the equilibrium of the system in the two pre-treatments. Once again the technique proposed in this work has two improvements. The sample does not need to be pre-treated and it is not necessary to use an indicator. This has the extra benefits of not incorporating a contaminant into the system and the influence in the value of the determination error as a consequence of the wide range of pH that they present.

On the other hand, when compared with the original technique it offers another application, with great accuracy and simplicity of operation. It is recommended to study the chemical kinetics to reduce the operation times.

Conclusions

In this research work, both experiments developed, reaction kinetics and conductimetric titration, showed that the working temperature is be properly maintained with a thermostat and remains stable to achieve determinations that can be compared with each other and avoid the fluctuation of the conductivity.

The nitrogen bubble system presents good results, not only because it is one that can be carried out within the thermostat, but also offers the process a liquid medium with features showing a tendency to isotropy. More work has to be done in this respect to guarantee isotropy, studying the flow of gas delivered into the system and the best position of the bubbler.

A suitable agitation throughout the experiment provides the liquid medium isotropic characteristics. This is a key condition for studying these systems ensuring the homogeneity of the medium in which the membrane under study is immersed. If the medium is not isotropic, values obtained are unreliable for the determination of total acid capacity or equivalent weight.

The best operational conditions are: working at the same temperature using a thermostat and suitable agitation of the system throughout the determination.

The study of the kinetics allows calculating the half-life period that abruptly reduces the long periods of time that have to wait to determine the value of TAC using other techniques. The time required to analyze a reaction with a half-life period of 30 min is of 6 h (for the whole experiment) in contrast to 24 h to acid–based titration to reach only reaction equilibrium, then the time needed to make the titration itself has to be taken into account.

The sample does not necessarily have to be pre-treated like the cases of the other conductometric titrations mentioned and the acid-based titration, and as a direct consequence the time of operation is reduced. The technique proposed offers advantages if it is compared with other techniques such as acid–base titration. As the determination does not need the presence of an indicator, it does not have the possible determination error for the wide range of pH that an indicator presents.

The technique designed does not need to dissolve the sample of polymeric material to be studied, so it is does not incorporate contaminants that can alter the results. The value of the total acid capacity can be obtained avoiding the pre-treatment of the material, and as a consequence the contamination of the sample with other types of electrolytes that can affect the results of the conductometric titration technique.

References

Smitha, B., Sridhar, S., Khan, A.A.: Solid polymer electrolyte membrane for fuel cell applications—a review. J. Membr Sci. 259, 10–26 (2005). doi:10.1016/j.memsci.2005.01.035

Carmo, M., Fritz, D.L., Mergel, J., Stolten, D.: A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy. 38, 4901–4934 (2013). doi:10.1016/j.ijhydene.2013.10.151

Barbir, F., Gómez, T.: Efficiency and economics of proton exchange membrane (PEM) fuel cells. Int. J. Hydrogen Energy. 21, 891–901 (1996). doi:10.1016/0360-3199(96)00030-4

Peighambardoust, S.J., Rowshanzamir, S., Amjadi, M.: Review of the proton exchange membranes for fuel cell applications. Int. J. Hydrogen Energy. 35, 9349–9384 (2010). doi:10.1016/j.ijhydene.2010.05.017

Mendham, J., Denney, R.C., Barnes, J.D., Thomas, K.: Vogel`s Textbook of Quantitative Chemical Analysis. Prentice Hall, England (2000)

Bochek, A.M., Zabivalova, N.M., Petropavlovskii, G.A.: Determination of the esterification degree of polygalacturonic acid. Russ. J. Appl. Chem. 74, 796–799 (2001). doi:10.1023/A:1012701219447

Waltz, J.E., Taylor, G.B.: Determination of molecular weight of nylon. Anal. Chem. 19, 448–450 (1947). doi:10.1021/ac60007a006

Erbil, C., Özdemir, S., Uyanik, N.: Determination of the monomer reactivity ratios for copolymerization of itaconic acid and acrylamide by conductometric titration method. Polymer. 41, 1391–1394 (2000). doi:10.1016/S0032-3861(99)00291-8

dos Santos, Z.M., Caroni, A.L.P.F., Pereira, M.R., da Silva, D.A., Fonseca, J.L.C.: Determination of deacetylation degree of chitosan: a comparison between conductometric titration and CHN elemental analysis. Carbohydr. Res. 344, 2591–2595 (2009). doi:10.1016/j.carres.2009.08.030

Okubo, M., Kanaida, K., Matsumoto, T.: Preparation of carboxylated polymer emulsion particles in which carboxyl groups are predominantly localized at surface layer by using the seeded emulsion polymerization technique. Journal of Applied Polymer Science. 33, 1511–1516 (1987). doi:10.1002/app.1987.070330507

Everett, D.H., Gülpete, M.E.: Reprints of Nato Advanced Study Institute on Polymer Colloids. University of Trondheim, Norway (1975)

Everett, D.H., Gültepe, M.E., Wilkinson, M.C.: Problems associated with the surface characterization of polystyrene lattices. Journal of Colloid and Interface Science. 71, 336–349 (1979). doi:10.1016/0021-9797(79)90244-3

Kolthoff, I.: Conductometric Titrations. Ind. Eng. Chem. 2, 225–230 (1930)

Righellato, E., Davies, C.: Conductometric analysis I. Acids and acid mixtures. Trans. Faraday Soc. 29, 429–437 (1933)

Lavorante, M., Franco, J.: Conductometric titration to analyze Nafion®117 conductivity. In: Oral, A.Y., Bahsi Oral, Z.B., Ozer, M. (eds.) 2nd International Congress on Energy Efficiency and Energy Related Materials (ENEFM2014), pp. 459-466. Springer Proceedings in Energy (2015)

Atkins, P.: Physical Chemistry. Addison-Wesley Iberoamericana, Mexico (1987)

Harland, C.: Ion Exchange Theory and Practice. Royal Society of Chemistry, Cambridge (1994)

Lavorante, M., Franco, J.: Nafion® and the study of the kinetics of neutralization and exchange reactions. In: Sutton, A. (ed.) Nafion: Properties, Structure and Applications, pp. 57–71. Nova Science Publishers, New York (2016)

Frost, A.A., Pearson, R.G.: Kinetics and Mechanism. A Study of Homogeneous Reactions. Wiley, New York-London (1961)

Laidler, K.J.: Chemical Kinetics. Harper & Row, New York (1987)

Lavorante, M.J., Franco J.I.: Nafion®117 and its neutralization reaction by conductometric titration. http://www.scienceknowconferences.com/files/extended_abstracts (2014). Accessed 15 Feb 2017

https://www.chemours.com/Nafion/en_US/assets/downloads/nafion-extrusion-cast-membranes-product-information.pdf. Accessed 15 Feb 2017

Acknowledgements

Authors want to thank the Defense Ministry for the PIDDEF 22/11 for the given support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lavorante, M.J., Franco, J.I. Conductometric titration as a technique to determine variation in conductivity in perfluorosulfonic acid materials for fuel cells and electrolyzers. Int J Energy Environ Eng 8, 123–134 (2017). https://doi.org/10.1007/s40095-017-0230-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-017-0230-z