Abstract

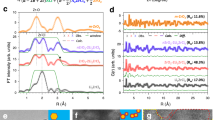

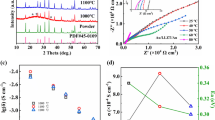

Garnet-type solid-state batteries (SSBs) are considered to be one of the most promising candidates to realize next-generation lithium metal batteries with high energy density and safety. However, the dendrite-induced short-circuit and the poor interfacial contact impeded the practical application. Herein, interface engineering to achieve low interfacial resistance without high temperature calcination was developed, which Li6.4La3Zr1.4Ta0.6O12 (LLZTO) was simply coated with complex hydride (Li4(BH4)3I (3L1L)) in various mass ratios n(Li4(BH4)3I)-(100−n)LLZTO (10 ≤ n ≤ 40). The interfacial conductivity increases by more than three orders of magnitude from 8.29 × 10−6 S·cm−1to 1.10 × 10−2 S·cm−1. Symmetric Li cells exhibit a high critical current density (CCD) of 4.0 mA·cm−2 and an excellent cycling stability for 200 h at 4.0 mA·cm−2. SSBs with polymeric sulfur-polyacrylonitrile (SPAN) cathode achieve a high discharge capacity of 1149 mAh·g−1 with a capacity retention of 91% after 100 cycles (0.2 C). This attempt guides a simple yet efficient strategy for obtaining a stable Li/LLZTO interface, which would promote the development of solid-state batteries.

Graphical abstract

摘要

本文设计了一种降低Li6.4La3Zr1.4Ta0.6O12(LLZTO)界面电阻的界面工程方法,整个过程无需长时间高温煅烧,在LLZTO表面制备了一系列具有不同质量比氢化物包覆的复合固态电解质n(Li4(BH4)3I)-(100‒n)LLZTO (10≤n≤40)。界面电导率从8.29×10−6 S·cm−1增加到1.10×10−2 S·cm−1,增加近4个数量级 临界电流密度高达4.0 mA·cm−2并且电池可以在4.0 mA·cm−2的电流密度中稳定循环超过200 h。组装的Li/SPAN 全固态电池在100次循环(0.2C)后维持1149 mAh·g−1的高放电容量,容量保持率为91%。这一尝试为获得稳定的Li/LLZTO界面提供了一种简单而有效的策略,这将有利于固态电池的发展。

Similar content being viewed by others

References

Liang FW, Xia YH, Zhang YL, Zhao SP, Yang SC, Liu XH. Lithium plating mechanism, model and fast charging strategy of lithium-ion batteries under fast charging condition. Chin J Rare Met. 2022;46(9):1235. https://doi.org/10.13373/j.cnki.cjrm.XY21030007.

Zhang TF, Isobe S, Matsuo M, Orimo SI, Wang YM, Hashimoto N, Ohnuki S. Effect of lithium ion conduction on hydrogen desorption of LiNH2-LiH solid composite. ACS Catal. 2015;5(3):1552. https://doi.org/10.1021/cs501782y.

Wei WQ, Liu BQ, Wang YQ, Yan K, Zhang H, Qi YS. Silicon-carbide fiber-reinforced polymer electrolyte for all-solid-state lithium-metal batteries. Rare Met. 2022;41(11):3774. https://doi.org/10.1007/s12598-022-02081-3.

Tang TY, Zhang LG, Guo ZF, Gu XX. Development of cathode and anode materials in lithium sulfur batteries. Chin J Rare Met. 2022;46(7):954. https://doi.org/10.13373/j.cnki.cjrm.XY21070001.

Wang Y, Zhan HY, Hu J, Liang Y, Zeng SS. Wet-laid non-woven fabric for separator of lithium-ion battery. J Power Sources. 2009;189(1):616. https://doi.org/10.1016/j.jpowsour.2008.09.078.

Feng XN, Zheng SQ, Ren DS, He XM, Wang L, Cui H, Liu X, Jin CY, Zhang FS, Xu CS, Hj H, Gao S, Chen TY, Li YL, Wang TZ, Hao W, Li MG, Ouyang MG. Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database. Appl Energy. 2019;246:53. https://doi.org/10.1016/j.apenergy.2019.04.009.

Huo HY, Chen Y, Luo J, Yang XF, Guo XX, Sun XL. Rational design of hierarchical “ceramic-in-polymer” and “polymer-in-ceramic” electrolytes for dendrite-free solid-state batteries. Adv Energy Mater. 2019;9(17):1804004. https://doi.org/10.1002/aenm.201804004.

Cao DX, Sun X, Li Q, Natan A, Xiang PY, Zhu HL. Lithium dendrite in all-solid-state batteries: growth mechanisms, suppression strategies, and characterizations. Matter. 2020;3(1):57. https://doi.org/10.1016/j.matt.2020.03.015.

Sakakura M, Mitsuishi K, Okumura T, Ishigaki N, Iriyama Y. Fabrication of oxide-based all-solid-state batteries by a sintering process based on function sharing of solid electrolytes. ACS Appl Mater Interfaces. 2022;14(43):48547. https://doi.org/10.1021/acsami.2c10853.

Huang ZY, Tong RA, Zhang J, Chen LH, Wang CA. Blending poly(ethylene oxide) and Li6.4La3Zr1.4Ta0.6O12 by Haake rheomixer without any solvent: a low-cost manufacture method for mass production of composite polymer electrolyte. J Power Sources. 2020;451:227797. https://doi.org/10.1016/j.jpowsour.2020.227797.

Lau J, DeBlock RH, Butts DM, Ashby DS, Choi CS, Dunn BS. Sulfide solid electrolytes for lithium battery applications. Adv Energy Mater. 2018;8(27):1800933. https://doi.org/10.1002/aenm.201800933.

Wu F, Fitzhugh W, Ye LH, Ning JX, Li X. Advanced sulfide solid electrolyte by core-shell structural design. Nat Commun. 2018;9(1):4037. https://doi.org/10.1038/s41467-018-06123-2.

Li XN, Liang JW, Adair KR, Li JJ, Li WH, Zhao FP, Hu YF, Sham TK, Zhang L, Zhao SQ, Lu SG, Huang H, Li RY, Chen N, Sun XL. Origin of superionic Li3Y1-xInxCl6 halide solid electrolytes with high humidity tolerance. Nano Lett. 2020;20(6):4384. https://doi.org/10.1021/acs.nanolett.0c01156.

Park KH, Kaup K, Assoud A, Zhang Q, Wu XH, Nazar LF. High-voltage superionic halide solid electrolytes for all-solid-state Li-ion batteries. ACS Energy Lett. 2020;5(2):533. https://doi.org/10.1021/acsenergylett.9b02599.

Zhang TF, Wang YM, Song T, Miyaoka H, Shinzato K, Miyaoka H, Ichikawa T, Shi SQ, Zhang XG, Isobe S, Hashimoto N, Kojima Y. Ammonia, a switch for controlling high ionic conductivity in lithium borohydride ammoniates. Joule. 2018;2(8):1522. https://doi.org/10.1016/J.JOULE.2018.04.015.

Zhang TF, Shao YF, Zhang X, Huang YQ, Wang S, Zhou W, Li P, Xia GL, Yu XB. Fast lithium ionic conductivity in complex hydride-sulfide electrolytes by double anions substitution. Small Methods. 2021;5(8):2100609. https://doi.org/10.1002/smtd.202100609.

Yang TQ, Wang C, Zhang WK, Xia Y, Gan YP, Huang H, He XP, Zhang J. Composite polymer electrolytes reinforced by a three-dimensional polyacrylonitrile/Li0.33La0.557TiO3 nanofiber framework for room-temperature dendrite-free all-solid-state lithium metal battery. Rare Met. 2022;41(6):1870. https://doi.org/10.1007/s12598-021-01891-1.

Wang X, Shen X, Zhang P, Zhou AJ, Zhao JB. Promoted Li+ conduction in PEO-based all-solid-state electrolyte by hydroxyl-modified glass fiber fillers. Rare Met. 2023;42(3):875. https://doi.org/10.1007/s12598-022-02218-4.

Ren YY, Shen Y, Lin YH, Nan CW. Direct observation of lithium dendrites inside garnet-type lithium-ion solid electrolyte. Electrochem commun. 2015;57:27. https://doi.org/10.1016/j.elecom.2015.05.001.

Huang ZY, Chen LH, Huang B, Xu BY, Shao G, Wang HL, Li YT, Wang CA. Enhanced performance of Li6.4La3Zr1.4Ta0.6O12 solid electrolyte by the regulation of grain and grain boundary phases. ACS Appl Mater Interfaces. 2020;12(50):56118. https://doi.org/10.1021/acsami.0c18674.

Wang TR, Duan J, Zhang B, Luo W, Ji X, Xu HH, Huang Y, Huang LQ, Song ZY, Wen JY, Wang CS, Huang YH, Goodenough JB. A self-regulated gradient interphase for dendrite-free solid-state Li batteries. Energy Environ Sci. 2022;15(3):1325. https://doi.org/10.1039/D1EE03604A.

Hong M, Dong Q, Xie H, Clifford BC, Qian J, Wang XZ, Luo J, Hu LB. Ultrafast sintering of solid-state electrolytes with volatile fillers. ACS Energy Lett. 2021;6(11):3753. https://doi.org/10.1021/ACSENERGYLETT.1C01554.

Weller JM, Dopilka A, Chan CK. Observation of elemental inhomogeneity and its impact on ionic conductivity in Li-conducting garnets prepared with different synthesis methods. Adv Energy Sustain Res. 2021;2(5):2000109. https://doi.org/10.1002/AESR.202000109.

Li ZC, Li TY, Deng YR, Tang WH, Wang XD, Yang JL, Liu Q, Zhang L, Wang Q, Liu RP. 3D porous PTFE membrane filled with PEO-based electrolyte for all solid-state lithium–sulfur batteries. Rare Met. 2022;41(8):2834. https://doi.org/10.1007/s12598-022-02009-x.

Guo QY, Xu FL, Shen L, Wang ZY, Wang J, He H, Yao XY. Poly(ethylene glycol) brush on Li64La3Zr14Ta06O12 towards intimate interfacial compatibility in composite polymer electrolyte for flexible all-solid-state lithium metal batteries. J Power Sources. 2021;498:229934. https://doi.org/10.1016/j.jpowsour.2021.229934.

Yu QJ, Jiang KC, Yu CL, Chen XJ, Zhang CJ, Yao Y, Jiang B, Long HJ. Recent progress of composite solid polymer electrolytes for all-solid-state lithium metal batteries. Chin Chem Lett. 2021;32(9):2659. https://doi.org/10.1016/j.cclet.2021.03.032.

Chen LH, Huang ZY, Chen SL, Tong RA, Wang HL, Shao G, Wang CA. In situ polymerization of 1,3-dioxolane infiltrating 3D garnet framework with high ionic conductivity and excellent interfacial stability for integrated solid-state Li metal battery. Rare Met. 2022;41(11):3694. https://doi.org/10.1007/S12598-022-02080-4/FIGURES/7.

Tong RA, Chen LH, Shao G, Wang HL, Wang CA. An integrated solvent-free modification and composite process of Li6.4La3Zr1.4Ta0.6O12/poly(ethylene oxide) solid electrolytes: enhanced compatibility and cycle performance. J Power Sources. 2021;492:229672. https://doi.org/10.1016/j.jpowsour.2021.229672.

Tong RA, Chen LH, Fan BB, Shao G, Liu RP, Wang CA. Solvent-free process for blended PVDF-HFP/PEO and LLZTO composite solid electrolytes with enhanced mechanical and electrochemical properties for lithium metal batteries. ACS Appl Energy Mater. 2021;4(10):11802. https://doi.org/10.1021/acsaem.1c02566.

Cheng AR, He X, Wang RX, Shan B, Wang KL, Jiang K. Low-cost molten salt coating enabling robust Li/garnet interface for dendrite-free all-solid-state lithium batteries. Chem Eng J. 2022;450:138236. https://doi.org/10.1016/j.cej.2022.138236.

Jia MY, Zhao N, Bi ZJ, Fu ZQ, Xu FF, Shi C, Guo XX. Polydopamine-coated garnet particles homogeneously distributed in poly(propylene carbonate) for the conductive and stable membrane electrolytes of solid lithium batteries. ACS Appl Mater Interfaces. 2020;12(41):46162. https://doi.org/10.1021/ACSAMI.0C13434.

Lim YH, Park JH, Lee HJ, Ku MJ, Kim YB. Rapid fabrication of lanthanum strontium cobalt ferrite (LSCF) with suppression of LSCF/YSZ chemical side reaction via flash light sintering for SOFCs. Nano Energy. 2021;90:106524. https://doi.org/10.1016/j.nanoen.2021.106524.

Chen SJ, Nie ZW, Tian FF, Nie L, Wei R, Yu JM, Gao TY, Sun ZR, Yang N, Liu W. The influence of surface chemistry on critical current density for garnet electrolyte. Adv Funct Mater. 2022;32(23):2113318. https://doi.org/10.1002/adfm.202113318.

Orue A, Arrese-Igor M, Cid R, Júdez X, Gómez N, López Del Amo JM, Manalastas W, Srinivasan M, Rojviriya C, Armand M, Aguesse F, López-Aranguren P. Enhancing the polymer electrolyte–Li metal interface on high-voltage solid-state batteries with Li-based additives inspired by the surface chemistry of Li7La3Zr2O12. J Mater Chem A. 2022;10(5):2352. https://doi.org/10.1039/D1TA08362G.

Qin ZW, Xie YM, Meng XC, Qian DL, Shan C, Mao DX, He G, Zheng Z, Wan L, Huang YX. Interface engineering for garnet-type electrolyte enables low interfacial resistance in solid-state lithium batteries. Chem Eng J. 2022;447:137538. https://doi.org/10.1016/j.cej.2022.137538.

Tong RA, Luo HL, Chen LH, Zhang JX, Shao G, Wang HL, Wang CA. Constructing the lithium polymeric salt interfacial phase in composite solid-state electrolytes for enhancing cycle performance of lithium metal batteries. Chem Eng J. 2022;442:136154. https://doi.org/10.1016/J.CEJ.2022.136154.

Tian YJ, Ding F, Zhong H, Liu C, He YB, Liu JQ, Liu XJ, Xu Q. Li6.75La3Zr1.75Ta0.25O12@amorphous Li3OCl composite electrolyte for solid state lithium-metal batteries. Energy Storage Mater. 2018;14:49. https://doi.org/10.1016/J.ENSM.2018.02.015.

Gao Y, Sun SY, Zhang X, Liu YF, Hu JJ, Huang ZG, Gao MX, Pan HG. Amorphous dual-layer coating: enabling high Li-ion conductivity of non-sintered garnet-type solid electrolyte. Adv Funct Mater. 2021;31(15):2009692. https://doi.org/10.1002/adfm.202009692.

Zhang X, Zhang TF, Shao YF, Cao HL, Liu ZH, Wang S, Zhang XG. Composite electrolytes based on poly(ethylene oxide) and lithium borohydrides for all-solid-state lithium-sulfur batteries. ACS Sustain Chem Eng. 2021;9(15):5396. https://doi.org/10.1021/acssuschemeng.1c00381.

Huang ZY, Pang WY, Liang P, Jin ZH, Grundish N, Li YT, Wang CA. A dopamine modified Li6.4La3Zr1.4Ta0.6O12/PEO solid-state electrolyte: enhanced thermal and electrochemical properties. J Mater Chem A. 2019;7(27):16425. https://doi.org/10.1039/C9TA03395E.

Wei SY, Ma L, Hendrickson KE, Tu ZY, Archer LA. Metal-sulfur battery cathodes based on PAN-sulfur composites. J Am Chem Soc. 2015;137(37):12143. https://doi.org/10.1021/jacs.5b08113.

Kim SY, Kim SK, Sun PC, Oh N, Braun PV. Reduced graphene oxide/LiI composite lithium ion battery cathodes. Nano Lett. 2017;17(11):6893. https://doi.org/10.1021/acs.nanolett.7b03290.

Donzelli M, Ferber T, Vanita V, Waidha AI, Müller P, Mellin M, Hausbrand R, Jaegermann W, Clemens O. On the surface modification of LLZTO with LiF via a gas-phase approach and the characterization of the interfaces of LiF with LLZTO as well as PEO + LiTFSI. Materials. 2022;15(19):6900. https://doi.org/10.3390/MA15196900.

Lu J, Amine K. Recent research progress on non-aqueous lithium-air batteries from Argonne national laboratory. Energies. 2013;6:6016. https://doi.org/10.3390/en6116016.

Plerdsranoy P, Wiset N, Milanese C, Laipple D, Marini A, Klassen T, Dornheim M, Gosalawit-Utke R. Improvement of thermal stability and reduction of LiBH4/polymer host interaction of nanoconfined LiBH4 for reversible hydrogen storage. Int J Hydrog Energy. 2015;40(1):392. https://doi.org/10.1016/J.IJHYDENE.2014.10.090.

Zhang XD, Shi JL, Liang JY, Wang LP, Yin YX, Jiang KC, Guo YG. An effective LiBO2 coating to ameliorate the cathode/electrolyte interfacial issues of LiNi0.6Co0.2Mn0.2O2 in solid-state Li batteries. J Power Sources. 2019;426:242. https://doi.org/10.1016/j.jpowsour.2019.04.017.

Lu FQ, Pang YP, Zhu MF, Han FD, Yang JH, Fang F, Sun DL, Zheng SY, Wang CS. A high-performance Li-B-H electrolyte for all-solid-state Li batteries. Adv Funct Mater. 2019;29(15):1809219. https://doi.org/10.1002/adfm.201809219.

Shi X, Pang Y, Wang B, Sun H, Wang X, Li Y, Yang J, Li HW, Zheng S. In situ forming LiF nanodecorated electrolyte/electrode interfaces for stable all-solid-state batteries. Mater Today Nano. 2020;10:100079. https://doi.org/10.1016/j.mtnano.2020.100079.

Kisu K, Kim SY, Oguchi H, Toyama N, Orimo SI. Interfacial stability between LiBH4-based complex hydride solid electrolytes and Li metal anode for all-solid-state Li batteries. J Power Sources. 2019;436:226821. https://doi.org/10.1016/j.jpowsour.2019.226821.

Xu XW, Du GF, Cui C, Liang JN, Zeng C, Wang SH, Ma Y, Li HQ. Stabilizing the halide solid electrolyte to lithium by a β-Li3N interfacial layer. ACS Appl Mater Interfaces. 2022;14(35):39951. https://doi.org/10.1021/acsami.2c09131.

Yu TW, Liang JW, Luo L, Wang LM, Zhao FP, Xu GF, Bai XT, Yang R, Zhao SQ, Wang JT, Yu JQ, Sun XL. Superionic fluorinated halide solid electrolytes for highly stable Li-metal in all-solid-state Li batteries. Adv Energy Mater. 2021;11(36):2101915. https://doi.org/10.1002/aenm.202101915.

Yang S, Takahashi M, Yamamoto K, Ohara K, Watanabe T, Uchiyama T, Takami T, Sakuda A, Hayashi A, Tatsumisago M, Uchimoto Y. Studies on the inhibition of lithium dendrite formation in sulfide solid electrolytes doped with LiX (X = Br, I). Solid State Ion. 2022;377:115869. https://doi.org/10.1016/j.ssi.2022.115869.

Wan HL, Zhang JX, Xia JL, Ji X, He XZ, Liu SF, Wang CS. F and N rich solid electrolyte for stable all-solid-state battery. Adv Funct Mater. 2022;32(15):2110876. https://doi.org/10.1002/ADFM.202110876.

Lou JT, Wang GG, Xia Y, Liang C, Huang H, Gan YP, Tao XY, Zhang J, Zhang WK. Achieving efficient and stable interface between metallic lithium and garnet-type solid electrolyte through a thin indium tin oxide interlayer. J Power Sources. 2020;448:227440. https://doi.org/10.1016/j.jpowsour.2019.227440.

Fu JM, Yu PF, Zhang N, Ren GX, Zheng S, Huang WC, Long XH, Li H, Liu XS. In situ formation of a bifunctional interlayer enabled by a conversion reaction to initiatively prevent lithium dendrites in a garnet solid electrolyte. Energy Environ Sci. 2019;12(4):1404. https://doi.org/10.1039/C8EE03390K.

Kang DM, Sardar S, Zhang R, Noam H, Chen JY, Ma LG, Liang WB, Shi CS, Lemmon JP. In-situ organic SEI layer for dendrite-free lithium metal anode. Energy Storage Mater. 2020;27:69. https://doi.org/10.1016/j.ensm.2020.01.020.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Nos. 52171180, 51802154, and 51971065), the National Science Fund for Distinguished Young Scholars (No. 51625102), the Innovation Program of Shanghai Municipal Education Commission (No. 2019-01-07-00-07-E00028), the Fundamental Research Funds for the Central Universities (No. NG2022005), the Open Fund for Graduate Innovation Base in Nanjing University of Aeronautics and Astronautics (No. xcxjh20210612), and partially supported by the Fundamental Research Funds for the Central Universities, NS2021043.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lv, YT., Zhang, TF., Hu, ZT. et al. High critical current density in Li6.4La3Zr1.4Ta0.6O12 electrolyte via interfacial engineering with complex hydride. Rare Met. 43, 692–701 (2024). https://doi.org/10.1007/s12598-023-02479-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-023-02479-7