Abstract

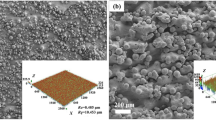

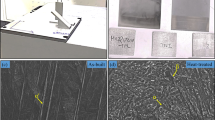

In the present study, corrosion properties and biocompatibility of as-built and as-polished Ti–6Al–4V samples fabricated by Electron Beam Melting (EBM) and Selective Laser Melting (SLM) were investigated and compared with a conventional sample as a reference. Optical microscope, Scanning Electron Microscope equipped with Energy Dispersive Spectroscopy, and X-ray diffraction analysis were employed for studying the microstructure and composition of the samples. Polarization, electrochemical impedance, and immersion tests were carried out to investigate the corrosion behavior and bioactivity of the samples in the Simulated Body Fluid solution. The results revealed that the EBM samples exhibited a superior corrosion resistance compared to the SLM one, thanks to the absence of low corrosion resistant α′ martensitic phases and a higher fraction of β phase in the EBM samples. It was also observed that while the wrought Ti–6Al–4V samples had a higher corrosion current density than the additively manufactured ones, both EBM and SLM processes had a lower corrosion resistance in the as-built state than in the as-polished. The immersion tests in the SBF solution revealed a more significant bioactivity for the EBM samples than the SLM samples. Higher levels of the β phase in the EBM microstructure stimulated the nucleation and growth of the apatite on the sample surface. Also, higher surface roughness in the as-built samples improved the bioactivity by increasing the metal/electrolyte interface and thus forming more OH− groups on the Ti alloy surface.

Graphical Abstract

Similar content being viewed by others

References

A. Saboori, D. Gallo, S. Biamino, P. Fino, M. Lombardi, An overview of additive manufacturing of titanium components by directed energy deposition: microstructure and mechanical properties. Appl. Sci. 7, 883 (2017). https://doi.org/10.3390/app7090883

M.H. Mosallanejad, B. Niroumand, A. Aversa, D. Manfredi, A. Saboori, Laser powder bed fusion in-situ alloying of Ti-5%Cu alloy: process-structure relationships. J. Alloys Compd. 857, 157558 (2021). https://doi.org/10.1016/j.jallcom.2020.157558

S.L. Sing, J. An, W.Y. Yeong, F.E. Wiria, Laser and electron-beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs. J. Orthop. Res. 34, 369–385 (2016). https://doi.org/10.1002/jor.23075

G. Del Guercio, M. Galati, A. Saboori, P. Fino, L. Iuliano, Microstructure and mechanical performance of Ti–6Al–4V lattice structures manufactured via electron beam melting (EBM): a review. Acta Metall. Sin. (Engl. Lett.) 33, 183–203 (2020). https://doi.org/10.1007/s40195-020-00998-1

A. Saboori, A. Abdi, S.A. Fatemi, G. Marchese, S. Biamino, H. Mirzadeh, Hot deformation behavior and flow stress modeling of Ti–6Al–4V alloy produced via electron beam melting additive manufacturing technology in single β-phase field. Mater. Sci. Eng. A 792, 139822 (2020). https://doi.org/10.1016/j.msea.2020.139822

M. Atapour, A.L. Pilchak, G.S. Frankel, J.C. Williams, Corrosion behavior of β titanium alloys for biomedical applications. Mater. Sci. Eng. C 31, 885–891 (2011). https://doi.org/10.1016/j.msec.2011.02.005

J. Karlsson, A. Snis, H. Engqvist, J. Lausmaa, Characterization and comparison of materials produced by electron beam melting (EBM) of two different Ti–6Al–4V powder fractions. J. Mater. Process. Technol. 213, 2109–2118 (2013). https://doi.org/10.1016/j.jmatprotec.2013.06.010

L.-C. Zhang, H. Attar, M. Calin, J. Eckert, Review on manufacture by selective laser melting and properties of titanium based materials for biomedical applications. Mater. Technol. 31, 66–76 (2016). https://doi.org/10.1179/1753555715Y.0000000076

T. Souflas, H. Bikas, M. Ghassempouri, A. Salmi, E. Atzeni, A. Saboori, I. Brugnetti, A. Valente, F. Mazzucato, P. Stavropoulos, A comparative study of dry and cryogenic milling for directed energy deposited IN718 components: effect on process and part quality. Int. J. Adv. Manuf. Technol. 119, 745–758 (2022). https://doi.org/10.1007/s00170-021-08313-7

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi, P. Fino, Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 9, 3316 (2019). https://doi.org/10.3390/app9163316

V. Dehnavi, J.D. Henderson, C. Dharmendra, B.S. Amirkhiz, D.W. Shoesmith, J.J. Noël, M. Mohammadi, Corrosion behaviour of electron beam melted Ti6Al4V: effects of microstructural variation. J. Electrochem. Soc. 167, 131505 (2020). https://doi.org/10.1149/1945-7111/abb9d1

M.H. Mosallanejad, B. Niroumand, A. Aversa, A. Saboori, In-situ alloying in laser-based additive manufacturing processes: a critical review. J. Alloys Compd. 872, 159567 (2021). https://doi.org/10.1016/j.jallcom.2021.159567

M. Galati, S. Defanti, A. Saboori, G. Rizza, E. Tognoli, N. Vincenzi et al., An investigation on the processing conditions of Ti–6Al–2Sn–4Zr–2Mo by electron beam powder bed fusion: microstructure, defect distribution, mechanical properties and dimensional accuracy. Addit. Manuf. 50, 102564 (2022). https://doi.org/10.1016/j.addma.2021.102564

S.H. Nedjad, M. Yildiz, A. Saboori, Solidification behaviour of austenitic stainless steels during welding and directed energy deposition. Sci. Technol. Weld. Join. 28, 1–17 (2022). https://doi.org/10.1080/13621718.2022.2115664

M. Galati, L. Iuliano, A literature review of powder-based electron beam melting focusing on numerical simulations. Addit. Manuf. 19, 1–20 (2018). https://doi.org/10.1016/j.addma.2017.11.001

L.-C. Zhang, H. Attar, Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: a review. Adv. Eng. Mater. 18, 463–475 (2016). https://doi.org/10.1002/adem.201500419

M. Roccetti Campagnoli, M. Galati, A. Saboori, On the processability of copper components via powder-based additive manufacturing processes: potentials, challenges and feasible solutions. J. Manuf. Process. 72, 320–337 (2021). https://doi.org/10.1016/j.jmapro.2021.10.038

A. Leon, G.K. Levy, T. Ron, A. Shirizly, E. Aghion, The effect of hot isostatic pressure on the corrosion performance of Ti–6Al–4V produced by an electron-beam melting additive manufacturing process. Addit. Manuf. 33, 101039 (2020). https://doi.org/10.1016/j.addma.2020.101039

A. Behjat, M. Shamanian, A. Taherizadeh, M. Noori, E. Lannunziata, L. Iuliano, A. Saboori, Enhanced surface properties and bioactivity of additively manufactured 316L stainless steel using different post-treatments. Mater. Today Proc. 70, 188–194 (2022). https://doi.org/10.1016/j.matpr.2022.09.019

X. Zhao, S. Li, M. Zhang, Y. Liu, T.B. Sercombe, S. Wang, Y. Hao, R. Yang, L.E. Murr, Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 95, 21–31 (2016). https://doi.org/10.1016/j.matdes.2015.12.135

H. Galarraga, D.A. Lados, R.R. Dehoff, M.M. Kirka, P. Nandwana, Effects of the microstructure and porosity on properties of Ti–6Al–4V ELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 10, 47–57 (2016). https://doi.org/10.1016/j.addma.2016.02.003

L.Y. Chen, J.C. Huang, C.H. Lin, C.T. Pan, S.Y. Chen, T.L. Yang, D.Y. Lin, H.K. Lin, J.S.C. Jang, Anisotropic response of Ti–6Al–4V alloy fabricated by 3D printing selective laser melting. Mater. Sci. Eng. A 682, 389–395 (2017). https://doi.org/10.1016/j.msea.2016.11.061

R. Li, J. Liu, Y. Shi, L. Wang, Balling behavior of stainless steel and nickel powder during selective laser melting process. Int. J. Adv. Manuf. Technol. 59, 1025–1035 (2012). https://doi.org/10.1007/s00170-011-3566-1

M. Fousová, D. Vojtěch, K. Doubrava, M. Daniel, C.-F. Lin, Influence of inherent surface and internal defects on mechanical properties of additively manufactured Ti6Al4V alloy: comparison between selective laser melting and electron beam melting. Materials 11, 537 (2018). https://doi.org/10.3390/ma11040537

E. Malekipour, H. El-Mounayri, Common defects and contributing parameters in powder bed fusion AM process and their classification for online monitoring and control: a review. Int. J. Adv. Manuf. Technol. 95, 527–550 (2018). https://doi.org/10.1007/s00170-017-1172-6

V. Viale, J. Stavridis, A. Salmi, F. Bondioli, A. Saboori, Optimisation of downskin parameters to produce metallic parts via laser powder bed fusion process: an overview. Int. J. Adv. Manuf. Technol. 123, 2159–2182 (2022). https://doi.org/10.1007/s00170-022-10314-z

W.S.W. Harun, N.S. Manam, M.S.I.N. Kamariah, S. Sharif, A.H. Zulki, I. Ahmad et al., A review of powdered additive manufacturing techniques for Ti–6al–4v biomedical applications. Powder Technol. 331, 74–97 (2018). https://doi.org/10.1016/j.powtec.2018.03.010

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina, R.B. Wicker, Microstructure and mechanical behavior of Ti–6Al–4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2, 20–32 (2009). https://doi.org/10.1016/j.jmbbm.2008.05.004

P. Chandramohan, S. Bhero, B.A. Obadele, P.A. Olubambi, Laser additive manufactured Ti–6Al–4V alloy: tribology and corrosion studies. Int. J. Adv. Manuf. Technol. 92, 3051–3061 (2017). https://doi.org/10.1007/s00170-017-0410-2

N. Dai, L.-C. Zhang, J. Zhang, Q. Chen, M. Wu, Corrosion behavior of selective laser melted Ti–6Al–4V alloy in NaCl solution. Corros. Sci. 102, 484–489 (2016). https://doi.org/10.1016/j.corsci.2015.10.041

Y. Bai, X. Gai, S. Li, L.-C. Zhang, Y. Liu, Y. Hao, X. Zhang, R. Yang, Y. Gao, Improved corrosion behaviour of electron beam melted Ti-6Al–4V alloy in phosphate buffered saline. Corros. Sci. 123, 289–296 (2017). https://doi.org/10.1016/j.corsci.2017.05.003

L.E. Murr, E. Martinez, K.N. Amato, S.M. Gaytan, J. Hernandez, D.A. Ramirez, P.W. Shindo, F. Medina, R.B. Wicker, Fabrication of metal and alloy components by additive manufacturing: examples of 3D materials science. J. Mater. Res. Technol. 1, 42–54 (2012). https://doi.org/10.1016/S2238-7854(12)70009-1

P. Metalnikov, G. Ben-Hamu, D. Eliezer, Corrosion behavior of AM–Ti–6Al–4V: a comparison between EBM and SLM. Prog. Addit. Manuf. 7, 509–520 (2022). https://doi.org/10.1007/s40964-022-00293-8

B. Zhao, H. Wang, N. Qiao, C. Wang, M. Hu, Corrosion resistance characteristics of a Ti–6Al–4V alloy scaffold that is fabricated by electron beam melting and selective laser melting for implantation in vivo. Mater. Sci. Eng. C 70, 832–841 (2017). https://doi.org/10.1016/j.msec.2016.07.045

G. Sander, J. Tan, P. Balan, O. Gharbi, D.R. Feenstra, L. Singer, S. Thomas, R.G. Kelly, J.R. Scully, N. Birbilis, Corrosion of additively manufactured alloys: a review. Corrosion 74, 1318–1350 (2018). https://doi.org/10.5006/2926

N. Dai, L.-C. Zhang, J. Zhang, X. Zhang, Q. Ni, Y. Chen, M. Wu, C. Yang, Distinction in corrosion resistance of selective laser melted Ti–6Al–4V alloy on different planes. Corros. Sci. 111, 703–710 (2016). https://doi.org/10.1016/j.corsci.2016.06.009

M. Neikter, P. Åkerfeldt, R. Pederson, M.-L. Antti, Microstructure characterisation of Ti–6Al–4V from different additive manufacturing processes. IOP Conf. Ser.: Mater. Sci. Eng. 258, 012007 (2017). https://doi.org/10.1088/1757-899X/258/1/012007

Y.P. Dong, J.C. Tang, D.W. Wang, N. Wang, Z.D. He, J. Li, D.P. Zhao, M. Yan, Additive manufacturing of pure Ti with superior mechanical performance, low cost, and biocompatibility for potential replacement of Ti–6Al–4V. Mater. Des. 196, 109142 (2020).

A. Sharma, M.C. Oh, J.-T. Kim, A.K. Srivastava, B. Ahn, Investigation of electrochemical corrosion behavior of additive manufactured Ti–6Al–4V alloy for medical implants in different electrolytes. J. Alloys Compd. 830, 154620 (2020). https://doi.org/10.1016/j.jallcom.2020.154620

Y.-L. Hao, S.-J. Li, R. Yang, Biomedical titanium alloys and their additive manufacturing. Rare Met. 35, 661–671 (2016). https://doi.org/10.1007/s12598-016-0793-5

Y. Xiao, N. Dai, Y. Chen, J. Zhang, S.-W. Choi, On the microstructure and corrosion behaviors of selective laser melted CP-Ti and Ti–6Al–4V alloy in Hank’s artificial body fluid. Mater. Res. Express 6, 126521 (2019). https://doi.org/10.1088/2053-1591/ab54d5

A.W.E. Hodgson, Y. Mueller, D. Forster, S. Virtanen, Electrochemical characterisation of passive films on Ti alloys under simulated biological conditions. Electrochim. Acta 47, 1913–1923 (2002). https://doi.org/10.1016/S0013-4686(02)00029-4

M. Atapour, A. Pilchak, G.S. Frankel, J.C. Williams, Corrosion behaviour of investment cast and friction stir processed Ti–6Al–4V. Corros. Sci. 52, 3062–3069 (2010). https://doi.org/10.1016/j.corsci.2010.05.026

T.M. Manhabosco, I.L. Müller, Erratum: tribocorrosion of diamond-like carbon deposited on Ti6Al4V (Tribology Letters DOI: 10.1007/s11249-009-9408-8). Tribol. Lett. 34, 229 (2009). https://doi.org/10.1007/s11249-009-9417-7

S. Tamilselvi, V. Raman, N. Rajendran, Corrosion behaviour of Ti–6Al–7Nb and Ti–6Al–4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim. Acta. 52, 839–846 (2006). https://doi.org/10.1016/j.electacta.2006.06.018

M. Atapour, X. Wang, M. Persson, I.O. Wallinder, Y.S. Hedberg, Corrosion of binder jetting additively manufactured 316L stainless steel of different surface finish. J. Electrochem. Soc. 167, 131503 (2020). https://doi.org/10.1149/1945-7111/abb6cd

F. Xie, X. He, S. Cao, M. Mei, X. Qu, Influence of pore characteristics on microstructure, mechanical properties and corrosion resistance of selective laser sintered porous Ti–Mo alloys for biomedical applications. Electrochim. Acta 105, 121–129 (2013). https://doi.org/10.1016/j.electacta.2013.04.105

M.R. Shabgard, H. Tavanaei, B. Khosrozadeh. Study the effect of electrical discharge machining (EDM) on residual stress and corrosion resistance of TI-6AL-4V Alloy. Mod. Mech. Eng. 18, 171–178 (2018). https://dorl.net/dor/20.1001.1.10275940.1397.18.3.51.2

H.B. Wen, J.R. De Wijn, F.Z. Cui, K. de Groot, Preparation of calcium phosphate coatings on titanium implant materials by simple chemistry. J. Biomed. Mater. Res. A 41, 227–236 (1998). https://doi.org/10.1002/(SICI)1097-4636(199808)41:2%3C227::AID-JBM7%3E3.0.CO;2-K

H. Qu, M. Wei, The effect of temperature and initial pH on biomimetic apatite coating. J. Biomed. Mater. Res. Part B 87, 204–212 (2008). https://doi.org/10.1002/jbm.b.31096

F.J. Gil, A. Padrós, J.M. Manero, C. Aparicio, M. Nilsson, J.A. Planell, Growth of bioactive surfaces on titanium and its alloys for orthopaedic and dental implants. Mater. Sci. Eng. C 22, 53–60 (2002). https://doi.org/10.1016/S0928-4931(01)00389-75

H. Takadama, H.-M. Kim, T. Kokubo, T. Nakamura, XPS study of the process of apatite formation on bioactive Ti–6Al–4V alloy in simulated body fluid. Sci. Technol. Adv. Mater. 2, 389–396 (2001). https://doi.org/10.1016/S1468-6996(01)00007-9

M.S. Tung, Calcium phosphates: structure, composition, solubility, and stability, in Calcium Phosphates in Biological and Industrial Systems, ed. by Z. Amjad (Springer, New York, 1998), pp. 1–19

X. Chen, A. Nouri, Y. Li, J. Lin, P.D. Hodgson, C. Wen, Effect of surface roughness of Ti, Zr, and TiZr on apatite precipitation from simulated body fluid. Biotechnol. Bioeng. 101, 378–387 (2008). https://doi.org/10.1002/bit.21900

Q. Wang, C. Han, T. Choma, Q. Wei, C. Yan, B. Song, Y. Shi, Effect of Nb content on microstructure, property and in vitro apatite-forming capability of Ti–Nb alloys fabricated via selective laser melting. Mater. Des. 126, 268–277 (2017). https://doi.org/10.1016/j.matdes.2017.04.026

H. Mokhtari, Z. Ghasemi, M. Kharaziha, F. Karimzadeh, F. Alihosseini, Chitosan-58S bioactive glass nanocomposite coatings on TiO2 nanotube: structural and biological properties. Appl. Surf. Sci. 441, 138–149 (2018). https://doi.org/10.1016/j.apsusc.2018.01.314

G.-l. Yang, F. He, X. Yang, X. Wang, S. Zhao, Bone responses to titanium implants surface-roughened by sandblasted and double etched treatments in a rabbit model. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 106, 516–524 (2008). https://doi.org/10.1016/j.tripleo.2008.03.017

A. Jemat, M.J. Ghazali, M. Razali, Y. Otsuka. Surface modifications and their effects on titanium dental implants. Biomed. Res. Int. 2015, 791725 (2015). https://doi.org/10.1155/2015/791725

P. Li, C. Ohtsuki, T. Kokubo, K. Nakanishi, N. Soga, K. de Groot, The role of hydrated silica, titania, and alumina in inducing apatite on implants. J. Biomed. Mater. Res. 28, 7–15 (1994). https://doi.org/10.1002/jbm.820280103

C.Q. Ning, Y. Zhou, In vitro bioactivity of a biocomposite fabricated from HA and Ti powders by powder metallurgy method. Biomaterials 23, 2909–2915 (2002). https://doi.org/10.1016/S0142-9612(01)00419-7

Z. Yang, S. Si, X. Zeng, C. Zhang, H. Dai, Mechanism and kinetics of apatite formation on nanocrystalline TiO2 coatings: a quartz crystal microbalance study. Acta Biomater. 4, 560–568 (2008). https://doi.org/10.1016/j.actbio.2007.10.003

Funding

Financial support was received from Avicenna Center of Excellence (ACE).

Author information

Authors and Affiliations

Contributions

MRB: Investigation, Validation, Data curation, Formal analysis, Writing Original draft. MHM: Conceptualization, Supervision, Writing-review & editing. MA: Conceptualization, Methodology, Data validation, Supervision, Writing-review & editing. LI: Supervision, Resources. AS: Conceptualization, Supervision, Writing-review & editing, Resources, Sample production, Data validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Consent to participate

The authors declare that they all consent to participate in this research.

Consent for publication

The authors declare that they all consent to publish the manuscript.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bandekhoda, M.R., Mosallanejad, M.H., Atapour, M. et al. Investigation on the Potential of Laser and Electron Beam Additively Manufactured Ti–6Al–4V Components for Orthopedic Applications. Met. Mater. Int. 30, 114–126 (2024). https://doi.org/10.1007/s12540-023-01496-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-023-01496-6