Abstract

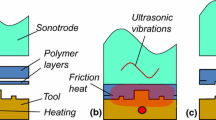

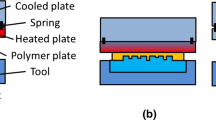

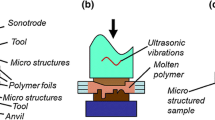

Ultrasonic welding of polymer micro structures is an economic and fast joining process but is also limited by the high need for geometrical accuracy required for tight and well-aligned joints. Melting of energy directors by ultrasound is nonhomogeneous especially when large parts are to be welded because the vibration amplitude is not the same everywhere under the sonotrode. This paper shows that the homogeneity of welding is improved by inserting metal parts between the joining partners.

Similar content being viewed by others

References

Daniels HPC (1965) Ultrasonic welding. Ultrasonics 3:190–196. https://doi.org/10.1016/0041-624X(65)90169-1

Domininghaus H (2012) Kunststoffe—Eigenschaften und Anwendungen. In: Elsner P, Eyerer P, Hirth T (eds) 8th edn. Springer, Heidelberg

Jung W, Ra J, Park K (2012) Design optimization of an ultrasonic horn for micro-pattern replication. Int J Precis Eng Manuf 13:2195–2201. https://doi.org/10.1007/s12541-012-0291-0

Kistrup K, Poulsen CE, Hansen MF, Wolff A (2015) Ultrasonic welding for fast bonding of self-aligned structures in lab-on-a-chip systems. Lab Chip 15:1998–2001. https://doi.org/10.1039/C5LC00174A

Kosloh J, Sackmann J, Šakalys R, Liao S, Gerhardy C, Schomburg WK (2017) Heat generation and distribution in the ultrasonic hot embossing process. Microsyst Technol 23:1411–1421. https://doi.org/10.1007/s00542-016-2836-0

Kosloh J, Sackmann J, Krabbe S, Schomburg WK (2018) Measurement of temperature and pressure distribution during ultrasonic processes by PVFD sensor foils. Microsyst Technol. https://doi.org/10.1007/s00542-018-3832-3

Liao S, Gerhardy C, Sackmann J, Schomburg WK (2015) Tools for ultrasonic hot embossing. Microsyst Technol 21:1533–1541. https://doi.org/10.1007/s00542-014-2232-6

Ng SH, Wang ZF, de Rooij NF (2009) Microfluidic connectors by ultrasonic welding. Microelectron Eng 86:1354–1357. https://doi.org/10.1016/j.mee.2009.01.048

Potente H (2004) Fügen von Kunststoffen—Grundlagen, Verfahren, Anwendungen. Carl Hanser, München

Sackmann J, Burlage K, Gerhardy C, Memering B, Liao S, Schomburg WK (2015) Review on ultrasonic fabrication of polymer micro devices. Ultrasonics 56:189–200. https://doi.org/10.1016/j.ultras.2014.08.007

Sun Y, Luo Y, Wang X, Zhang M, Feng Y (2011) A new ultrasonic precise bonding method with ultrasound propagation feedback for polymer MEMS. Microelectron Eng 88:3049–3053. https://doi.org/10.1016/j.mee.2011.05.018

Sun Y, Luo Y, Wang X (2012) Micro energy director array in ultrasonic precise bonding for thermoplastic micro assembly. J Mater Process Technol 212:1331–1337. https://doi.org/10.1016/j.jmatprotec.2012.01.013

Sun Y, Wang F, Li F, Yang X (2016) Study on vibration transmission and interfacial fusion in ultrasonic bonding process for thermoplastic micro joint. Adv Polym Technol. https://doi.org/10.1002/adv.21780

Truckenmüller R, Cheng Y, Ahrens R, Bahrs H, Fischer G, Lehmann J (2006) Micro ultrasonic welding: joining of chemically inert polymer microparts for single material fluidic components and systems. Microsyst Technol 12:1027–1029. https://doi.org/10.1007/s00542-006-0136-9

Zhang Z, Luo Y, Wang X, Zheng Y, Zhang Y, Wang L (2010) A low temperature ultrasonic bonding method for PMMA microfluidic chips. Microsyst Technol 16:533–541. https://doi.org/10.1007/s00542-010-1027-7

Acknowledgements

The authors want to thank Herrmann Ultrasonics for providing access to welding machines and advice, and the German Federal Ministry of Education and Research for financial support under fund number 18803 N/2 for the project µDiff granted by the industrial community research (IGF).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hoehr, L., Bavendiek, J., Sackmann, J. et al. Ultrasonic welding of polymer micro fluidic devices by inserting metal parts. Microsyst Technol 25, 673–681 (2019). https://doi.org/10.1007/s00542-018-3995-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-018-3995-y