Abstract

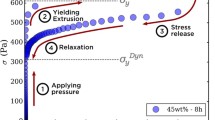

We investigate the yielding and recovery of silver pastes with industrial applications under dynamic shear conditions by means of the recently developed “sequence of physical processes” (SPP) approach. The SPP framework is unique as it allows insights to be gained regarding yielding and recovery processes on timescales significantly faster than the period of oscillation, with the temporal resolution limited only by the data acquisition time. This resolution allows for the accurate determination of yielding of soft materials under any predetermined preshear history, and at timescales that are relevant to the applications of these materials. The behavior of these pastes is shown to be significantly different than previously assumed, with yielding occurring shortly after the reversal of strain in an oscillation, and the observation of a rate-dependent shear-thickening effect. Yielding is also shown to occur far below what would typically be defined as the flow condition. The relative rates and timescales for yielding and recovery are also assessed. The results in this paper are an important step toward a more comprehensive understanding of the yielding and recovery of yielding materials.

Similar content being viewed by others

Notes

The screen backside is referred to within the photovoltaic industry as an emulsion, since it is made by curing an emulsion onto the screen via a lithographic process.

References

Balmforth NJ, Frigaard IA, Ovarlez G (2014) Yielding to stress: recent developments in viscoplastic fluid mechanics. Annu Rev Fluid Mech 46:121–146

Barnes HA (1989) Shear-thickening (“dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol 33:329

Barnes HA (1999) The yield stress—a review or ‘παντα ρει’—everything flows? J Non-Newtonian Fluid Mech 81:133–178

Bender J, Wagner NJ (1996) Reversible shear thickening in monodisperse and bidisperse colloidal dispersions. J Rheol 40:899

Bian X, Litvinov S, Ellero M, Wagner NJ (2014) Hydrodynamic shear thickening of particulate suspension under confinement. J Non-Newtonian Fluid Mech 213:39–49

Bonn D, Denn MM, Berthier L, Divoux T, Manneville S (2017) Yield stress materials in soft condensed matter. Rev Mod Phys 89:035005

Brown E, Jaeger HM (2014) Shear thickening in concentrated suspensions: phenomenology, mechanisms and relations to jamming. Rep Prog Phys 77:046602

Brown E, Forman NA, Orellana CS et al (2010) Generality of shear thickening in dense suspensions. Nat Mater 9:220–224

Buzby D, Dobie A (2008) Fine line screen printing of thick film pastes on silicon solar cells. In Procedings of the 41st International Symposium on Microelectronics 610:645–649

Casson N (1959) Rheology of disperse systems. In: Mill CC (ed) Flow equation for pigment oil suspensions of the printing ink type. Pergamon, London, pp 84–102

Cho KS, Hyun K, Ahn KH, Lee SJ (2005) A geometrical interpretation of large amplitude oscillatory shear response. J Rheol 49:747

Coussot P (2016) Bingham’s heritage. Rheol Acta 56:163–176. https://doi.org/10.1007/s00397-016-0983-y

Coussot P (2018) Slow flows of yield stress fluids: yielding liquids or flowing solids? Rheol Acta 57:1–14

Coussot P, Malkin AY, Ovarlez G (2017) Introduction: yield stress—or 100 years of rheology. Rheol Acta 56:161–162

Davit Y, Peyla P (2008) Intriguing viscosity effects in confined suspensions: a numerical study. Europhys Lett 83:64001

de Souza Mendes PR, Thompson RL, Alicke AA, Leite RT (2014) The quasilinear large-amplitude viscoelastic regime and its significance in the rheological characterization of soft matter. J Rheol 58:537–561

Dimitriou CJ, Ewoldt RH, McKinley GH (2013) Describing and prescribing the constitutive response of yield stress fluids using large amplitude oscillatory shear stress (LAOStress). J Rheol 57:27

Dinkgreve M, Paredes J, Denn MM, Bonn D (2016) On different ways of measuring “the” yield stress. J Non-Newtonian Fluid Mech 238:233–241

Dinkgreve M, Denn MM, Bonn D (2017) “Everything flows?”: elastic effects on startup flows of yield-stress fluids. Rheol Acta 56:189–194

Ewoldt RH, McKinley GH (2017) Mapping thixo-elasto-visco-plastic behavior. Rheol Acta 56:195–210. https://doi.org/10.1007/s00397-017-1001-8

Ewoldt RH, Hosoi AE, McKinley GH (2008) New measures for characterizing nonlinear viscoelasticity in large amplitude oscillatory shear. J Rheol 52:1427

Ewoldt RH, Winter P, Maxey J, McKinley GH (2010) Large amplitude oscillatory shear of pseudoplastic and elastoviscoplastic materials. Rheol Acta 49:191–212

Fernandes RR, Andrade DEV, Franco AT, Negrado COR (2017) The yielding and the linear-to-nonlinear viscoelastic transition of an elastoviscoplastic material. J Rheol 61:893

Galiazzo M, Voltan A, Bortoletto E et al (2015) Fine line double printing and advanced process control for cell manufacturing. Energy Procedia 67:116–125. https://doi.org/10.1016/j.egypro.2015.03.295

Giacomin AJ, Bird RB, Johnson LM, Mix AW (2011) Large-amplitude oscillatory shear flow from the corotational Maxwell model. J Non-Newtonian Fluid Mech 166:1081–1099

Herschel WH, Bulkley R (1926) Konsistenzmessungen von Gummi-Benzollösungen. Kolloid-Z. 39:291–300

Hoffman RL (1998) Explanations for the cause of shear thickening in concentrated colloidal suspensions. J Rheol 42:111

Hsu CP, Guo RH, Hua CC, Shih CL, Chen WT, Chang TI (2013) Effect of polymer binders in screen printing technique of silver pastes. J Polym Res 20:277. https://doi.org/10.1007/s10965-013-0277-3

Hyun K, Wilhelm M, Klein CO, Cho KS, Nam JG, Ahn KH, Lee SJ, Ewoldt RH, McKinley GH (2011) A review of nonlinear oscillatory shear tests: analysis and application of large amplitude oscillatory shear (LAOS). Prog Polym Sci 36:1697–1753

Jiang JS, Liang JE, Yi HL, Chen SH, Hua CC (2016) Performances of screen-printing silver thick films: rheology, morphology, mechanical and electronic properties. Mater Chem Phys 176:96–103. https://doi.org/10.1016/j.matchemphys.2016.03.032

Klein CO, Spiess HW, Calin A, Balan C, Wilhelm M (2007) Separation of the nonlinear oscillatory response into a superposition of linear, strain hardening, strain softening, and wall slip response. Macromolecules. 40:4250–4259

Lin HW, Chang CP, Hwu WH, Der GM (2008) The rheological behaviors of screen-printing pastes. J Mater Process Technol 197:284–291. https://doi.org/10.1016/j.jmatprotec.2007.06.067

Malkin A, Kulichikhin V, Ilyin S (2017) A modern look on yield stress fluids. Rheol Acta 56:177–188

Maranzano BJ, Wagner NJ (2001) The effects of particle size on reversible shear thickening of concentrated colloidal dispersions. J Chem Phys 114:10514

Mari R, Seto R, Morris JF, Denn MM (2014) Shear thickening, frictionless and frictional rheologies in non-Brownian suspensions. J Rheol 58:1693

Owczarek JA, Howland FL (1990a) A study of the off-contact screen printing process. I. Model of the printing process and some results derived from experiments. IEEE Transactions on Components, Hybrids, and Manufacturing Technology 13:358–367. https://doi.org/10.1109/33.56169

Owczarek JA, Howland FL (1990b) A study of the off-contact screen printing process. II. Analysis of the model of the printing process. IEEE Transactions on Components, Hybrids, and Manufacturing Technology 13:368–375. https://doi.org/10.1109/33.56170

Park JD, Rogers SA (2018) The transient behavior of soft glassy materials far from equilibrium. J Rheol 62:869

Peyla P, Verdier C (2011) New confinement effects on the viscosity of suspensions. Europhys Lett 94:44001

Phair JW, Kaiser A (2009) Determination and assessment of the rheological properties of pastes for screen printing ceramics. Annual Transactions of the Nordic Rheology Society 17:177–182 Retrieved from http://wwwnysv.sik.se/nrs/Open_transactions/2009/Oralpresentations/Application of Rheology/Phair_Kaiser 2009.pdf

Phair JW, Lundberg M, Kaiser A (2009) Leveling and thixotropic characteristics of concentrated zirconia inks for screen-printing. Rheol Acta 48:121–133. https://doi.org/10.1007/s00397-008-0301-4

Pospischil M, Zengerle K, Specht J et al (2011) Investigations of thick-film-paste rheology for dispensing applications. Energy Procedia 8:449–454. https://doi.org/10.1016/j.egypro.2011.06.164

Pospischil M, Specht J, Gentischer H et al. (2012) Correlations between finger geometry and dispensing paste rheology. In 27th European photovoltaic solar energy conference and exhibition 1773–1776. doi:https://doi.org/10.4229/27thEUPVSEC2012-2CV.5.51

Pospischil M, Klawitter M, Kuchler M et al (2013a) Process development for a high-throughput fine line metallization approach based on dispensing technology. Energy Procedia 43:111–116. https://doi.org/10.1016/j.egypro.2014.02.001

Pospischil M, Specht J, Markus K, Matthias H, Mohr C, Clement F, Biro D (2013b) Paste rheology correlating with dispensed finger geometry. IEEE Journal of Photovoltaics 4:1–6

Pospischil M, Fellmeth T, Brand A et al (2014) Optimizing fine line dispensed contact grids. Energy Procedia 55:693–701. https://doi.org/10.1016/j.egypro.2014.08.046

Pospischil M, Kuchler M, Klawitter M et al (2015) Dispensing technology on the route to an industrial metallization process. Energy Procedia 67:138–146. https://doi.org/10.1016/j.egypro.2015.03.297

Pospischil M, Klawitter M, Kuchler M et al (2016) High speed dispensing with novel 6″ print head. Energy Procedia 98:61–65. https://doi.org/10.1016/j.egypro.2016.10.081

Rogers SA (2012) A sequence of physical processes determined and quantified in LAOS: an instantaneous local 2D/3D approach. J Rheol 56:1129–1151

Rogers SA (2017) In search of physical meaning: defining transient parameters for nonlinear viscoelasticity. Rheol Acta 56:501–525

Rogers SA, Lettinga MP (2012) A sequence of physical processes determined and quantified in large-amplitude oscillatory shear (LAOS): application to theoretical nonlinear models. J Rheol 56:1–25

Rubinstein M, Colby RH (2003) Polymer physics. New York Publisher, Oxford

Taroni M, Breward CJW, Howell PD, Oliver JM, Young RJS (2011) The screen printing of a power-law fluid. J Eng Math 73:93–119. https://doi.org/10.1007/s10665-011-9500-6

Thibert S, Jourdan J, Bechevet B, Chaussy D, Reverdy-Bruas N, Beneventi D (2014) Influence of silver paste rheology and screen parameters on the front side metallization of silicon solar cell. Mater Sci Semicond Process 27:790–799. https://doi.org/10.1016/j.mssp.2014.08.023

Trappe V, Prasad V, Cipelletti L, Segre PN, Weitz DA (2001) Jamming phase diagram for attractive particles. Nature 411:772–775

van der Sman RGM (2009) Simulations of confined suspension flow at multiple length scales. Soft Matter 5:4376–4387

Wagner NJ, Brady JF (2009) Shear thickening in colloidal dispersions. Phys Today 62:27

Yoshimura AS, Prud’homme RK (1987) Response of an elastic Bingham fluid to oscillatory shear. Rheol Acta 26:428–436

Acknowledgments

The authors thank the DuPont Photovoltaics R&D team members for their discussions and providing material, particularly Mike Pottiger, Qijie Guo, Mike Wolfe, Kirby Liao, Hoang Vi Tran, and Hee Hyun Lee. S. A. R. acknowledges the financial support from the Department of Chemical and Biomolecular Engineering at the University of Illinois at Urbana-Champaign.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Donley, G.J., Hyde, W.W., Rogers, S.A. et al. Yielding and recovery of conductive pastes for screen printing. Rheol Acta 58, 361–382 (2019). https://doi.org/10.1007/s00397-019-01148-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-019-01148-w