On a freshly cut tree the moisture content can be anywhere from 30%-45%, this is called green wood and some chair makers use this wood for their projects, but for the rest of us the MC is too high to build anything from it, so we, have to dry the lumber before it is of any use to us. The ideal MC for furniture making is around 8-9%, some say 7 and some say 6, so let’s just say anywhere from 7-9% is ideal.

There are two ways to dry your timber, air drying which is a slower process and kiln drying a much faster forced process. Let’s look at Air drying first.

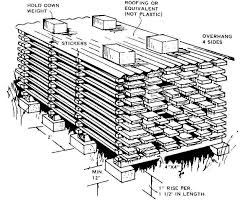

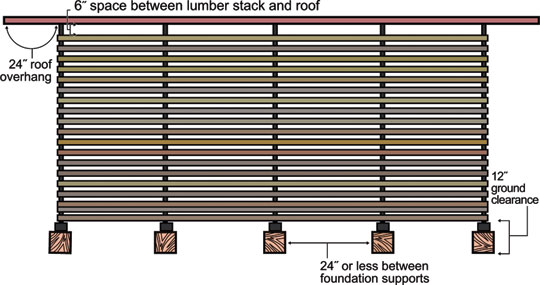

Air drying is a lengthy process usually each board takes 1 inch (25mm) per one year to dry, the lumber is stacked off the ground 15-24 inch(400-600mm) on stickers which are placed across the boards and inline to each below, and above in between the boards to avoid sagging to gain even weight distribution. The stickers serve to allow air flow between each board.

A canopy or preferably plywood with cinder blocks or other heavy items should be placed on top. The canopy or plywood is there to protect the timber from weather elements, plywood is preferred over the canopy because it allows air flow and protection from the sun. If you use a canopy you should remove it when it’s not raining. Once the boards have reached equilibrium with its environment which is usually about 15% outside, you then need to bring it into your shop to acclimate, and continue to dry until they reach the 7-9% MC. Depending on your own environment this can take from two weeks up to a month or more.

A canopy or preferably plywood with cinder blocks or other heavy items should be placed on top. The canopy or plywood is there to protect the timber from weather elements, plywood is preferred over the canopy because it allows air flow and protection from the sun. If you use a canopy you should remove it when it’s not raining. Once the boards have reached equilibrium with its environment which is usually about 15% outside, you then need to bring it into your shop to acclimate, and continue to dry until they reach the 7-9% MC. Depending on your own environment this can take from two weeks up to a month or more.

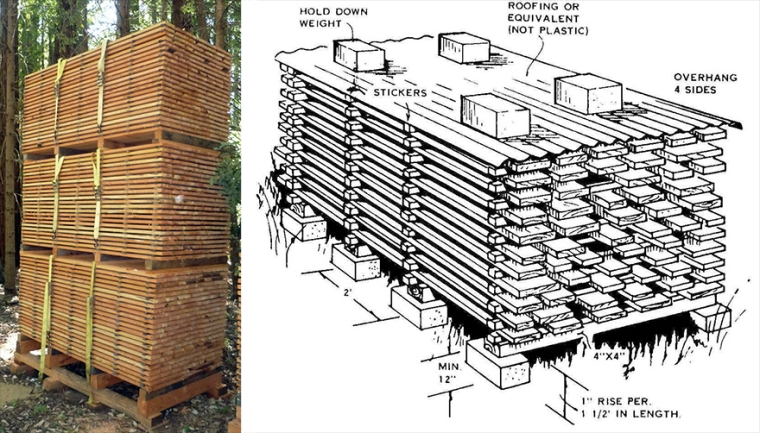

Air drying needs to be in an open space not surrounded by trees or other plant life, the ground mustn’t be damp either. If any of these features are present, then the lumber will continually absorb the MC from its surroundings and not dry properly and mould may start to form, mould is notorious in pine and other woods. Below is a picture of what I’m referring too. The picture on the left shows the timber stacked surrounded by other trees. These stacked timbers will continually absorb large amounts of moisture from the surrounding trees and damp ground.

The pictures below are ideally the type of environment it should be air dried.

Unfortunately for many of us who are not financially endowed, we have to make do with the surroundings we have. It just means that once the timber has reached equilibrium with its surroundings, which may well be above 15% and then brought into the shop, we will have to wait longer than usual for the stuff to dry thoroughly or acclimate before it’s ready for use. It pays to have a high quality moisture meter, a Wagner is a good choice. I prefer a pinless version which costs anywhere from $200 upto $900. They are every bit as accurate as the pinned type, even though some will disagree. I will do a blog on this for sure.

Air dried lumber is a hand tool woodworkers best friend, it’s easy to work and is more stable than kiln dried lumber because it’s not forced dried through high temperatures, but rather a natural slower process. As the timber air dries the cells collapse, slowly causing them to compress and stay put, so when air dried lumber absorbs moisture, it doesn’t swell as much hence it becomes more stable. Many people including myself find kiln dried wood more physically demanding to work with hand tools.

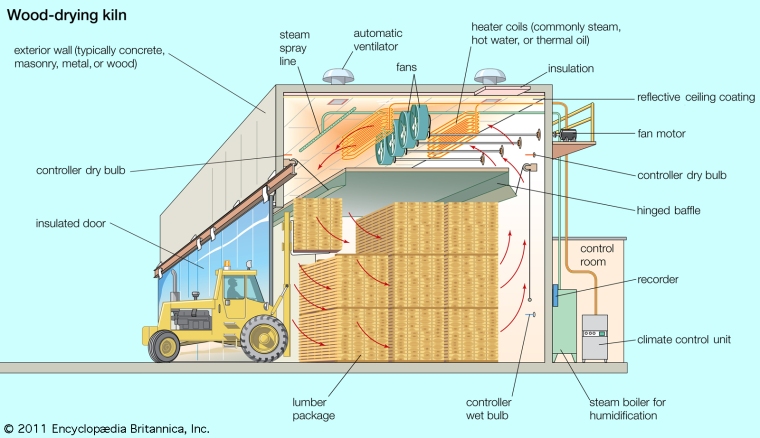

Kiln Drying

Kiln dried is a forced but controlled process where humidity and temperature is controlled using steam and fans for drying. The drying process normally takes between 6-8 weeks, because of its fast drying due to high temperatures, the cells collapse quickly rather than slowly as it would with air drying, making it unstable. Because of this when moisture is absorbed, the cells expand rapidly filling up with water quickly than it would with air dried lumber. However, the positives with Kiln drying due to high temperatures, any laid eggs and bugs are killed off. There is treatment for mould and insects at an extra cost.

If hot dry air is used, then the surface dries too rapidly and develops case hardening, ‘checks’, so kiln drying requires careful control of both air and temperature. The idea is to prevent stagnant layer of excessively humid air from lingering around the timber, as in the case of air drying, the air is frequently renewed which prevents this from happening.

Final Notes:

My personal preference goes to air dried lumber as you might have already gathered, having worked with both kiln and air dried, and being a hand tool woodworker, I can certainly see and feel the difference between the two. The seeing is a visual difference. Air dried lumber has a rich colour over kiln dried stuff. Also planning seems to be a lot easier and more pleasurable not requiring so much physical exertion to perform these basic tasks. Lastly kiln drying can cause a lot of internal tensions which can make the timber brittle. Cambia which is oven baked to extreme temperatures to change its colour from white which is white ash to black is very brittle. They claim this makes it more stable and resists any cupping, warping etc. but I beg to differ as once re sawn cupping is inevitable even though the effects are not immediate, but if left to sit freely without pressure applied on top it will cup, this does not work all the time. When planning you don’t get shavings but more like, I don’t know what you’d call it so here is a picture of it,  and if dropped will shatter like glass. So you can imagine, after scrolling for an hour every intricate detail and you accidentally drop it and just shatters, it’s enough to make you cry, and cried I have. Cambia really is a wonderful looking timber and does take an excellent finish, but doesn’t take screws nor nails well. Even though it has all the anomalies of staying away from it, I will at every opportunity use it only because of it’s appearance. Since I cannot afford ebony this is the next best thing to it. Also anything above 1/4″ thick makes it very strong. The cost; well it’s bloody expensive is all I can say, and I don’t know why, in it’s natural state it’s half the price. Now they have extended its range to Poplar which looks really nice, imagine that, they’ve made a second rate timber to something attractive.

and if dropped will shatter like glass. So you can imagine, after scrolling for an hour every intricate detail and you accidentally drop it and just shatters, it’s enough to make you cry, and cried I have. Cambia really is a wonderful looking timber and does take an excellent finish, but doesn’t take screws nor nails well. Even though it has all the anomalies of staying away from it, I will at every opportunity use it only because of it’s appearance. Since I cannot afford ebony this is the next best thing to it. Also anything above 1/4″ thick makes it very strong. The cost; well it’s bloody expensive is all I can say, and I don’t know why, in it’s natural state it’s half the price. Now they have extended its range to Poplar which looks really nice, imagine that, they’ve made a second rate timber to something attractive.

For machine work, obviously kiln dried lumber won’t have any effect on you physically, but none the less you still may experience some chip out, loss of colour and internal tensions on some boards when re sawing. Just the other day I was re sawing American Black Walnut, and just as I finished the cut, it did with a loud bang as the two pieces separated and immediately cupped, even though this board has been sitting inside my shop for the last two or three years. Once a board has tension in it, it will remain until it’s released, even if it sat untouched for 100 years. That’s life.

Here is a video a visual description summary of what I’ve written above.

A few weeks ago I ripped a board in 4 pieces (I was upcycling a 3 or 4 years plank) and one middle piece was totally twisted, cupped and bowed… WHAT? I dig in the web and got my confirmation about kiln dried lumber.

This article is very useful one -at least for me- since some times I ‘make some experiences’ drying fire wood for my projects!

Thanks

LikeLike

That will happen when it isn’t dried properly just like my black walnut. Thanks to their carelessness it’s a constant nightmare to work with.

LikeLiked by 1 person

Where do you get your movements from? In the past few years I noticed the quality of the quartz movements I was using were going downhill. Lots more plastic, very rare to find a glass lens, and largely coming out of China. My source for Seiko movements went out of business.

LikeLike

Most of mine came from Germany and the US. I bought a large quantity as I too started to face the same problem. If you buy from Germany you will pay a premium price but your also getting the best. Many suppliers from the USA and Australia are buying from Taiwan and even though they aren’t the same quality as you would get from Germany they are accurate and will last about 30 years which is remarkable when you think about it. The ones that come from India I don’t know much about but some suppliers don’t recommend them even though they stock them, ironic isn’t it. Finding quality movements that are attractive has been a constant up hill battle for me.

LikeLike