Fresh thinking is the answer to today’s challenges.

The challenges facing the agricultural sector are becoming increasingly bigger. And when times are tough, only one thing helps: a new way of thinking. Envisaging alternative options and making smart decisions. For your next tractor purchase, this means opting for efficiency instead of image. For a tractor that can do tough work with top performance whilst under constant strain. And all that at a reasonable price. A Kubota tractor is exactly the right alternative at times like these.

For all requirements

The Kubota new generation RM series has two headstocks with the designations 200 and 300. Both are constructed from the highest quality steel and are subject to Kubota’s special heat treatment processes which infuse additional properties such as strength and hardness. Strong sealed roller bearings are used for years of trouble-free and maintenance free service.

Headstock 200

For intensive ploughing and tractors up to 200 hp. Trouble free 120 mm heat treated monoblock hollow shaft, fitted with sealed roller bearings. Cross shaft Cat. II and III. Optional square scross shaft cat. III with clevis.

Headstock 300

Built for heavy duty. High quality 150 mm heat treated hollow shaft made from only one piece. Cross shaft Cat. III and IV. Optional square cross shaft cat. III/IV with clevis.

Did you know?

Did you know that Kubota produces its own engines and that Kubota is the global market leader for industrial diesel engines under 100 hp? You might be surprised to learn under which bonnets Kubota engines are at work. Top quality and ef ficiency are the main ingredients of this success.

Smooth and safe turnover

The headstocks employ a strong 80 mm turnover cylinder, positioned at the rear of the headstock mast, to give correct and safe turnover.

The design retains the proven Kubota concept of having the centre of gravity close to the tractor in order to minimise lift requirement and to improve stability.

Clever layout of hoses

To avoid the risk of hose damage during the turnover operation, the majority of the hoses pass through the main support axle – no hose pass over the turning point of the headstock. Even the valve block is integrated.

Transport in “butterfly”

The transport lock for transport in “butterfly” position is an option for the RM4005V and is standard for the RM6005V and RM6105V.

Front furrow width adjustment

As standard equipment, front furrow width adjustment is via a turnbuckle. Hydraulic cylinders can be specified as an option.

Sequence valve

The sequence valve controls the reversing cycle of the plough. It ‘narrows’ the plough width to 12” (30cm) before reversing. Once the cycle is completed, it returns automatically to the pre-set furrow width. This system gives a smoother reversal of the plough.

The memory valve is fitted to the 4, 5, 6 furrow Variomat® ploughs of the RM4005V/RM6005/RM6105V series, depending on countries.

Quick coupling

The RM4005V features the quick coupling.

Variation on the move

Kubota Variomat® system allows the optimal match between the soil conditions, the plough and the tractor for the maximum output. Kubota‘s patented Variomat® is the most reliable system on the market. It also ensures the correct parallel linkage along the whole plough. The pulling line adjustments are hence automatic. The benefits are easy handling, low draft requirements, low wear and tear.

By varying the furrow width, the work can be kept straighter. It is also easier to work up to the hedges, and any obstacles.

50 cm/20" 30 cm/12"

Auto-Line

Kubota Auto-line system is a standard device which guarantees the correct pulling line at any time. When changing the working width, both front furrow width and pulling line adjust accordingly. Kubota Auto-line system makes these adjustments automatically. The position of the headstock remains in the center of the tractor, all the time, ensuring a favorable and an even geometry of the three point linkage. Side pull and unnecessary high landside pressure are therefore avoided. Consequently, the Kubota Auto-line system ensures an efficient ploughing with less fuel consumption.

Minimum wear

The heat-treated mainframe together with the bolt, distance tube, two cones and bushes ensure a unique non-wearing pivot joint between the beams and the mainframe.

“on

the move”

Kubota Variomat® allows adjustments of the furrow width from the driver’s seat ‘on the move’. The practicality of being able to determine not only the depth, but also the width of the furrows is crucial if the best results are to be achieved. The pulling line adjusts automatically thanks to the auto-line.

Save time and fuel

By changing the ploughing width from 35 to 45 cm, the output increases by 30% with the same plough. This higher performance is actually achieved at a lesser cost. It induces a 18% reduction is fuel consumption partly due to the low pulling requirements of Kubota bodies.

The Variomat® is also the solution to the demanding spring ploughing season when weather conditions are so unpredictable. Efficiency and quality ploughing can then be combined.

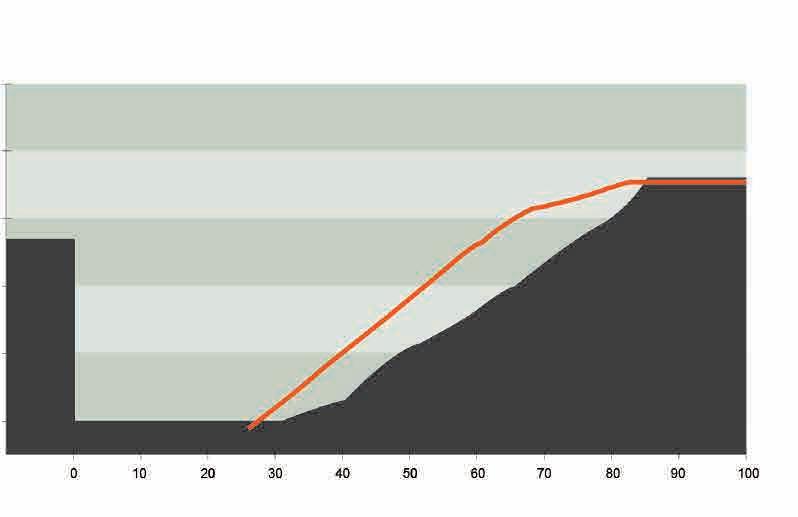

Release pressure on share point (kp)

Release height (cm)

Release characteristics

The diagram shows the differences between three different Non-stop systems, (Hydraulic system, Coil spring system and the clever Kubota leaf spring system) and how the pressure varies as the body rises (1 cm).

Bene fi ts

The Kubota leaf spring Non-stop system is highly recommended. When hitting an obstacle, the pressure on the point, frame, plough parts, decreases.

The stress on the plough is therefore reduced which guarantees a longer life to the plough and ensures a better ploughing.

Ef ficient in stony conditions

Kubota Non-stop system guarantees a quality ploughing. The legs release independently one from another. Once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

A reliable System

The simple multi-leaf spring system allows the plough legs to release over stones and other solid objects in the ground in a smooth and efficient manner. This avoids sudden jolts and possible damage.

Quicker than ever Easy adjustment of release forces: unscrew 2 bolts to add or remove 1 leaf spring .

Simple and easy

Kubota’s Non-stop system is a very simple construction and yet is able to withstand these punishing forces year in, year out, with a minimum of maintenance.

Extra leaves when needed

The Non-stop system includes 8+1 Kubota heat treated springs (17 kN).

Designed for high performance

Kubota bodies benefit from an outstanding design for high agronomic performance and for low wearing.

Low pull requirement

Recent university studies, FH Cologne and Wilsmann 2012, have revealed that the design of Kubota bodies offer some of the lowest pulling forces on the market: from -20% to -42% when ploughing at 20 cm working depth and -11% to -24% at 30 cm. It is therefore possible to plough with 1 extra Kubota body and gain in output compared to competition. As regard to fuel consumption, it is reduced by 19% to 28% when using a Kubota plough.

Wide choice of bodies

Kubota has designed bodies which are adapted to any soils conditions.

Body No. 28:

The answer for ploughing with wide tyres

Wide empty furrow

Body No.28 shape and action moves the soil further away from the landside, increases the furrow bottom width by as much as 25% compared to Body No.9. This allows wide tractor tyres lile a 710 serie type, to work in the furrow without rolling down the previous furrow.

Low pulling forces

Body No.28 is suitable for depths from 15 to 30 cm (6 to 12 inches) and widths from 35 to 50 cm (14 to 20 inches).

Longer than body No.8, it creates a flatter profile for improved tilth. The furrow is well turned and packed. Body No.28 clever design will require as little pulling force as Body No. 8 or 9.

Bene fi ts:

• very wide empty furrow – ground preserving tyres

• easy pulling and therefore low fuel consumption

• good turning and well packed

• good trash burial

• perfect universal body for all soils

Body No. 8

• general purpose body

• for light to heavy soils

• working depth: 15-28 cm

• working width: 30-50 cm

• landside / mouldboard: 40°

Body No. 9

• universal body

• for light and medium soil

• easy to pull

• working depth: 18-30 cm

• working width: 30-50 cm

• landside / mouldboard: 40°

• universal body – easy to pull

• for any soil conditions

• recommended for tractors with large tyres

• creates a flatter profile for improved tilth

• perfect turning of the furrow slice

• working depth: 15-30 cm

• working width: 35-50 cm

• landside / mouldboard: 40°

Body No. 34

•

• long and slim shape (similar to Body 28)

• for soils with high humus content without stones

• advised for tractors with large tyres

• easy pulling

• working depth: 12-35 cm

• working width: 30-55 cm

• Landside / mouldboard:40°

Body No. 30

• finger mouldboard with 4 exchangeable strips

• plastic spacers

• for any soil conditions

• intensive crumbling

• working depth: 18-35 cm

• working width: 30-55 cm

• landside / mouldboard: 46°

Smart & safe transport

The Trailer Transport Solution is an option for the Kubota mounted reversible models RM4005V, RM6005V and RM6105V.

Trailer Transport Solution

Safety during transport is optimised for the driver and for anyone/anything around. The new generation of Kubota ploughs behave like a trailer thanks to a turnable cross shaft (45 degree mutual offset). There is no tilting when driving in curves.

Quick and easy

It only takes 1 minute to convert the plough position from transport to ploughing: remove the two pins placed in the headstock and one for the wheel.

Aero-profile legs for the best soil flow

The new generation of Kubota ploughs feature the aero-profiles legs: 80 cm underbeam clearance.

A new design

Not only higher than the standard Kubota legs, these new legs improve soil flow: heavy residues are pushed out, hence limiting possible blockages even with an 85 cm interbody clearance.

Robust

The aero-profile legs are hollow and robust thanks to a specific heat treatment technology. By limiting the weight of the legs, the Kubota ploughs are lighter, easy to lift and to pull. Low pulling forces saves fuel consumption.

Centrally adjusted skimmers

For the best ploughing results, skimmers need to be adjusted.

The correct depth

For the perfect ploughing, adjusting the depth and the angle of the skimmers are important. Residues are hence placed in the soil profile where desired.

Centrally adjusted skimmers

Right and left skimmers are adjustable from the center, simultaneously to the expected depth. This quick operation saves a lot of time.

The adjustment of the skimmer angle is equally quick and easy by moving only 1 bolt.

These new solutions contribute to making ploughing more efficient.

Perfect for medium to heavy-tough soil conditions

RM4005V series is designed for tractors up to 225 Hp: 25-45 Hp per body depending on soil conditions. Even in tough and stony conditions, high ploughing performance can be reached.

Did you know?

Did you know that Kubota is not only one of the top-50 most recognised brands in Japan, but also one of the largest tractor manufacturers in the world?

In 2020 alone, Kubota produced more than 270,000 tractors.

During turnover at headlands, an alignment cylinder incorporated within the main frame reduces stress on both tractor and plough. This optional memory system ensures that the desired furrow width setting is maintained following the plough reversing cycle.

On sloping grounds, if the mechanical front furrow width adjustment is standard, a hydraulic cylinder is recommended. It controls the front furrow width “on the Move”.

The Kubota RM4005V is a Variomat® plough that adapts to any tractors. When activating the Variomat®, the front furrow is repositioned automatically. Therefore, the working width is kept equal from first to last body. It guarantees the precision of the overall ploughing performance.

A perfect ploughing implies setting skimmers at the correct depth. The skimmers slice off the top soil to place it efficiently at the bottom of the furrow. The adjustment of the depth of the Kubota skimmers is central, easy and quick.

Optimised robustness

Comfort with easy adjustments

The Variomat® is activated from the tractor cabin. The working width varies from 30-50 cm or 35-55 cm for 85 cm or 100 cm interbody clearance. In addition, the Auto-line system corrects the pulling line automatically. This provides a real working comfort to the driver and low wear to soil parts.

The 100 x 200 mm one box section frame is induction heat treated to gain the necessary strength for arduous conditions. No welding in order to avoid weaknesses. The headstock 200 with its mono block turnover axle guarantees the required robustness for trouble free operations.

Re-consolidation

The Kubota Packomat is ideal for an immediate re-consolidation of the ploughed soil. 2 operations in one saves time. Alternatively, the Kubota packer arm is also available.

Designed for the toughest soil conditions

The Kubota RM6005V series is built for tractors up to 330 Hp: 30-55 Hp per body depending on soil conditions. These are robust ploughs, easy to adjust for any soil conditions.

Built for the toughest conditions

The Kubota RM6005V is equipped with the headstock 300, meant for trouble free operations in the toughest conditions. The 120 x 200 mm induction heat treated frame is made of a single box section. No welding that could weaken the frame.

Designed for up to 6 furrows, this plough offers ploughing capacity in any soil conditions. Reputed for its low lift requirements and very low pulling forces, the fuel consumption is minimized. The low draft implies low wearing of soil parts and high ploughing performance.

Optimized ef ficiency

The Kubota RM6005V models are available from 4 to 6 furrows. Your plough can grow with your fields. Depending on the configuration of your fields, 2 positions for the wheel are possible: the rear mounted wheel provides the best stability for the highest ploughing performance. The frame mounted wheel enables ploughing more at the closest to fences, ditches etc…

The choice of 85/100 cm interbody clearance and the 80 cm underbeam clearance facilitate ploughing for high performance.

The Kubota packer arm and the Packomat are available for the soil re-consolidation.

“On the Move” adjustments

Soil conditions can vary a lot field to field and even in the same field. Keep on ploughing by adjusting the ploughing width “On the Move”. Likewise, the working window for ploughing is sometimes fairly short and conditions not optimal. The Variomat® is the solution to plough in all type of soil conditions. The front furrow repositions itself automatically. The pulling line adjusts automatically for the best ploughing performance in full comfort. At headlands, a memory system ensures that the chosen furrow width setting is maintained following the plough reversing cycle. On sloping grounds, a hydraulic cylinder is recommended to control the front furrow width “on the Move”.

High capacity and low operating cost

The Kubota RS7005V series can plough any soil conditions up to stony or wet. The Variomat ® and the very large wheel are ideal for high ploughing performances.

Variations “On the Move”

The Kubota RS7005V ploughs consist of robust 5-8 furrow models designed for large acreages. The Variomat® facilitates easy “On the Move” working width changes whenever necessary. Whereas the manual front furrow width adjustment is by means of a turnbuckle; for “On the Move” adjustments when ploughing on sloping ground, an hydraulic cylinder can be fitted as an alternative.

High ploughing performance

The large rear wheel enables a high stability especially in wet conditions. It limits sinking and compaction. The plough is stable to guaranty a quality plouhing. The rear position of the wheel results in a well balance weight transfer from the wheel of the plough to the tractors rear wheels. Consequently, the plough is easy to pull. Fuel consumption is hence optimised to its strick minimum. The easy pulling effect minimises the wear of parts while the ploughing performance are maximised.

Outstanding Non-stop

The aero-profile legs and the 80 cm under beam clearance enable easy ploughing in high residues. Not least, the Non-stop system enables high ploughing performance even in heavy and stony soils conditions. Easy adjustment of releasing forces.

Easy headland

The rear wheel assembly is linked hydraulically to a robust turnover mechanism ensuring that the plough is always positioned correctly for re-entry into work. The hydraulic system provides a small reversing radius and an excellent manoeuvrability during work and transportation.

Easy changeover from work to transport position

For transport, the plough is placed in half-reversed position within seconds. Its low centre of gravity ensures a safe transport. Even where space is restricted, the plough can be steered with ease around obstacles

Robust for long lasting

The induction heat treated 200 x 200 mm frame, one box section with no welding that could weaken it, ensures the robustness of the plough.

The three point linkage feature prevents high forces on the tractor during ploughing and transportation which lingers the tractor life time. Choice of Cat. III/IV.

For soil re-consolidation

Ploughing alone benefits most soils. Re-consolidation after ploughing or before seeding increases productivity and favours higher yields.

PRESSURE BULBS

PACKER RING SECTION

SOIL SURFACE

Agronomic bene fi ts

The combination of ploughing and re-consolidating is both efficient and environmentally friendly. Soils are loosened, organic matters are incorporated to enrich the soils. Weeds are controlled mechanically. The elevation of temperature of the ploughed soil is actually positive. The associated water evaporation is limited by the immediate re-consolidation via packers. Water capilarity is hence re-established for the benefit of the soil life.

Maximise ef ficiency

Driven by efficient crop management processes, as a farmer, it is difficult to grant sufficient time for the soil to settle by itself. Furthermore, soil moisture shall be maintained to ensure a good germination after seeding.

Kubota Packomat re-consolidating tool is therefore recommended in combination with ploughing or directly before seeding. Coarse clods get crushed, soil is re-consolidated with a favourable soil moisture.

PLOUGHING DEPTH

Higher profi tability

Profitability is generally improved by either cutting down costs or improving yields. By re-consolidating soils either during ploughing or directly before seeding, the profitability improves on both ends. Cost are reduced by completing 2 operations simultaneously. The fuel consumption is optimised too. Yields will improved due to the re-consolidation of the soils.

For soil re-consolidation

The Packomat follows the Kubota plough from work to transport while the Kubota Packer arm can be used on most of the Kubota ploughs for packers.

Did you know?

Did you know that Kubota manufactures products in seven European countries?

This proximity to the market is central to the company’s philosophy. Each factory adheres to the same high Japanese quality standards, whether it is located in Germany, France, or Japan.

Kubota packer arm

Available for most Kubota mounted reversible ploughs and for all packers, the packer arm is connected to the headstock in order to minimize additional side forces during ploughing. Quick, easy and smooth operations thanks to the hydraulic release system and to the spring system which absorbs shocks. Simple manual handling for transport position.

Packer arm

Packomat ef ficiency

Packomat works in all ploughing conditions. It levels, re-consolidates, crushes clods, prepares seed beds, from light-dry to heavy-wet soils.

Packomat is rigidly mounted via a packer arm. The latter is made of a specially hardened spring steel. By means of that arm, weight transfer takes place from the plough to the Packomat to ensure that the packer works the soil with the correct “field pressure”.

Easy packing pressure adjustments

More than 1250 kg pressure gets easily regulated by means of a turnbuckle or an optional hydraulic cylinder.

Optimised levelling

The choice of front harrows helps crush clods and eases the ring soil reconsolidation.

Low pulling forces

The Packomat does not require any extra pulling force than for the plough alone. The support of the depth wheel on one side and the Packomat on the other side, balance even better the plough. Less landside pressure actually reduces the draft requirements.

Easy handling

100% integrated Packer

Packomat follows the plough from transport to work. This is done easily from the tractor cabin. The Packomat can also remain lifted on field bounderies.

Compared to other packers, the Packomat offers high productivity gains. There is no need for extra manpower.

Easy

The only tools needed are a chisel and a hammer (2 kg). Field tests reveal that, as an average, 3 points can be mounted on the same Knock-on® holder. No bolt to unscrew helps save time. In addition, when the holder is worn out, it is normally also time to change the share, without unscrewing the holder. Very handy!

Quick & easy

The Knock-on® system consists of only 2 parts: a holder fixed to a regular Kubota share and a Knock-on® point.

Easy

The only tools needed are a chisel and a hammer (2 kg). Field tests reveal that, as an average, 3 points can be mounted on the same Knock-on® holder. No bolt to unscrew helps save time. In addition, when the holder is worn out, it is normally also time to change the share, without unscrewing the holder. Very handy!

Agronomic bene

fi ts

Knock-on® has been tested in several soil conditions. Even in the hardest soils, the points ensure a good penetration. Hence, the plough stays stable in work which ensures quality ploughing results.

Clever

Kubota’s Knock-on® is a universal system. Plough Knock-on® points can also be used for cultivators.

Long lasting Knock-on® benefits from the Kubota steel technology for low wear. The quality of the steel combined with a clever design ensure a long life to the Knock-on® system. Therefore, Knock-on® points can be used in any soil conditions.

Quick

Knock-on® points are changed in a few seconds. It makes sense to save 90% of your time in changing points when working in abrasive soils (points wear quicker) or when having a 5+ furrow plough.

Low pulling forces

Kubota bodies generate very low pulling forces. With Knock-on® points, the pulling forces remain low and hence the fuel consumption.

Soil flow protection

The clever design of Knock-on® actually protects the other parts of the body while allowing an efficient soil flow.

Accessories

Shares with Reversible Points

The most cost effective ‘share’ system for ploughing hard and abrasive soils and generally, difficult conditions.

Trashboards

Particularly useful for large quantities of surface trash: manure, straw, etc. are present.

Sword Share Knives

These are an alternative to disc coulters, either to reduce weight or to avoid blockage from trash or stones. Can only be used on ploughs fitted with reversible points.

Furrow Splitter

Bolted to any parts of the mouldboard or share, the furrow splitter is designed to cut through heavy soils making it easier for following operations.

Landside Knives

A very good alternative to disc coulters, either to reduce weight, or to avoid blockage from trash or stones. A good combination with skimmers.

Quick Release coupling

For quick and easy hitching and unhitching.

Disc Coulters: plain or notched

Disc coulters are available in sizes of 45, 50 and 55 cm (18, 20 or 22“) diameter. They are mounted on single arms. Easy to adjust to suit all conditions.

XHD accessories

Carbides spare parts combined to Kubota steels for extreme soil conditions. Keep downtime to a minimum.

Ef ficient farming: discover the possibilities

Kubota’s precision farming offering consists of innovative and custom made equipment, designed to manage your farm with success. Now you can carry out the work in a smarter, more efficient and easier way to get the best out of your machines and crops, as well as saving time and money in fertiliser, chemicals and seeds.

Be a PRO in increasing productivity

The IsoMatch Tellus PRO 12-inch terminal provides you with the optimal solution for an all-in-one control system inside the tractor cab including automatic steering. It is the centre for connecting all ISOBUS machines, running precision farming applications and Farm Management Systems. It offers everything you need to get the maximum out of your machines and crop, as well as cost savings in fertiliser, chemicals and seeds by using automatic section control and variable rate control. With the unique dual screen functionality it gives you the opportunity to view and manage two machines and/or processes simultaneously.

Easy control management

The IsoMatch Tellus GO is a cost-efficient 7-inch terminal, especially developed for managing the machine in a simple way. You are in full control of the machine in exactly the way you want. Easily set up the machine with the soft keys via the 7-inch touch screen and for optimal control while driving simply use the hard keys and rotary switch. Controlling the implement has never been so easy.

Did

IsoMatch Grip

This ISOBUS auxiliary device is made for maximum machine control and efficient farming. Operate up to 44 implement functions per machine.

100%

focus, the best performance

As tractor steering with IsoMatch AutoDrive-E is handled automatically, you have the freedom to control and monitor your work in an easy way. While the work is more efficient and overlaps are avoided, you can completely focus on the result in the field. (Only in combination with IsoMatch Tellus PRO).

Advanced precision farming software

IsoMatch GEOCONTROL is an advanced software application within the IsoMatch terminals that helps you to control all ISOBUS compatible Kubota machines. Combined with a GPS receiver it fulfils the future needs in terms of innovative and efficient farming! The IsoMatch GEOCONTROL precision farming application includes Manual Guidance and Data Management free of charge. It is possible to expand this application with Section Control and/ or Variable Rate Control.

Enhance your success with E-learning IsoMatch Simulator is a free downloadable virtual training program. It simulates all functions of the IsoMatch Universal Terminals and Kubota ISOBUS machines. Train yourself and make yourself familiar with your machine to avoid errors and enhance your machine performance.

IsoMatch Global

The IsoMatch Global is the GPS antenna, with DGPS accuracy, in the IsoMatch product range. It enables satellite navigation for site-specific section control, variable rate application, manual guidance and field registration

IsoMatch InLine

Light bar for manual guidance including section status information. Manage the distance from the A-B line and steer for the ideal position.

IsoMatch (Multi)Eye

Connect up to 4 cameras to the IsoMatch Universal Terminals. It gives you full control and overview of the entire machine operation.

Kubota Farm Solutions

360º performance for 100% success

We understand that you need more than a powerful tractor to succeed: namely, an integrated system of products and services to increase your competitiveness and preparation for the future. With Kubota Farm Solutions, we have brought together our solutions in a system – and targeted our proposition to you. From intelligent technology to individual services, the Kubota Farm Solutions advantages complement each other, forming a circle that ends where it begins: with our commitment to support you a little better every time, now and in the future.

Performance

You have a clear objective: to get your work done productively and successfully while being relaxed. Kubota offers you the equipment that can best support you in this endeavour. Whichever tractor or implements you decide on, you can always count on proven quality, excellent performance, and co-ordinated features. In short: intelligent and reliable technology that gets you a decisive step closer to your goal.

Control

You want full control over what you are doing. Kubota provides you with perfectly integrated systems to help you achieve that. From machine optimisation to implement monitoring, you can control the tractor and resources easily from a single terminal. This not only provides you with a better overview of all work processes, but also allows you to work without stress.

Optimisation

You know exactly how you want to get your work done: efficiently, precisely, and most comfortably. Kubota gives you everything you need to obtain optimal results while remaining at ease. With our ISOBUS technology, precision farming solutions, and automatic steering system, you can apply seeds, fertilisers, and pesticides with extreme precision. This lowers your costs and reduces your workload.

Value protection

You know what it takes to be commercially successful: top performance with every task and top conditions over many years. Once again, Kubota offers solutions that fulfil what they promise. Our parts are manufactured to the same high standards and strict specifications as the Kubota machines.

Finance management

You want to improve your productivity, but not at any cost. With Kubota Finance, you can make your planned investment with ease, convenience, and safety. Whether financing or leasing, you benefit from professional advice and attractive conditions. All you need in order to gain the advantages of a technology that drives your success forward. Whether you need machines or services, you have full control of the costs.

Perfection.

Technical data

Model Interbody clearance cm Headstock Type of beam Working width cm Underbeam clearance cm No. of furrows

Kubota RM4005V 85/100 Nº 200 Autom. 30-50/35-55 80 3-5

Kubota RM6005V 85/100 Nº 300 Autom. 30-50/35-55 80 4-6

Kubota RM6105V 85/100 Nº 300 Autom. 30-50/35-55 80 5-7 (6+1)/5-6

Kubota RS7005V 100 Autom. 35-55 80 6-8 Kubota RS7005V 115 Autom. 35-55 80 5-7

Model Weight (kg) Lift requirements (kg) 3 4 5 6 7 8 3 4 5 6 7 8

Kubota RM4005V 1180 1470 1630 - - - 3100 4300 5100 - - -

Kubota RM6005V - 1700 2000 2300 - - - 4900 6300 8200 -Kubota RM6105V - - 2200 2400 2680 - - - 7000 8500 9000 -

Model Weight (kg) Horse power requirements (hp) 3 4 5 6 7 8 3 4 5 6 7 8

Kubota RS7005V (100) - - - 3340 3720 4100 - - - 180 210 240 Kubota RS7005V (115) - - 3060 3430 3820 - - - 150 180 210 240

Most mounted reversible models can be extended by one body. All weights are given without optional equipment (net weights).

The lift-requirements are given with the following equipment: depth wheel, one coulter and skimmers for all furrows. Weights and lifting requirements are given for ploughs with 85 cm ‘interbody clearance’.

For ploughs with 100 cm clearance, please adjust according to the following: Weight + 15 kg/body, lifting requirement + 50 kg/body.

Most ploughs with stepless ploughing width and interbody clearance of 85 cm have a working width between 30-45 cm, while ploughs with 100 cm have a working width between 35-50 cm.

* for 100 cm interbody clearance only ** only 85 cm Interbody clearance

https://www.kubota-eu.com/en/ag

This publication may not be reproduced in whole or in part in any form without the prior written consent of KUBOTA. It corresponds to the status at the time of going to press. The manufacturer reserves the right to change technical specifications without notice. Some of the parts shown in the publication are optional and are not part of the standard equipment. Information on warranty and safety as well as further product information can be obtained from the responsible KUBOTA authorized dealer.