The Port of Opportunities

The Port of HaminaKotka is a versatile Finnish seaport serving trade and industry. The biggest universal port in Finland is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

Dear Readers,

When dispatching the ‘Season’s Greetings’ e-newsletter last year, we did not wish you for 2022 to return to some pre-corona “normal,” realising that times are – and will continue to be – hard. We were, unfortunately, prophetic, as just two months into the year, a barbaric war was set in motion just around the Baltic Sea region’s corner. I would like to take this opportunity and wish our neighbours in Ukraine freedom, peace & swift recovery. Many worldwide – and from our corner of the globe, too – had, are, and will support your efforts. I tip my hat to their generosity, but, most of all, salute you for your bravery and fortitude. Our Dear Readers, around this special time of the year as well as in the coming months, please remember about & aid those most in need. I am acutely aware of the biting inflation; yet, there are things, there are important things, and there are also Important Things. A Big Thank You in advance!

Other than that, this is your latest & greatest instalment of our journal, as always packed to the brim with stellar reads. Traditionally, the year’s last issue hosts an analysis of Baltic and European shipyards’ performance. Because we also publish the updated version of the New Silk Road Map by year-end, the Report section features a China-focused article, this time from the Mercator Institute for China Studies, on what we can expect from Xi’s third tenure. There is also a follow-up piece to the ‘gender’ article from BTJ 5/22, with another round-up of why the maritime industry keeps women at bay – for all the wrong reasons. The sector’s reluctance to let more female seafarers in and provide them with better working conditions is nothing more than an exercise in futility.

Other splendid reads also put the finger on the industry’s pain points, including the rough sea towards climate neutrality. Bureau Veritas highlights why we need to start measuring greenhouse gas emissions on a well-to-wake basis to move the sustainability needle. Another class, the American Bureau of Shipping, takes us closer to why carbon capture & storage on board ships can make a big difference. Regarding future marine fuels, SEA-LNG nuances the bunker discussion by getting into the nitty-gritty of CO2 reductions of the different forms liquefied natural gas can come in. In turn, Ballard Power Systems makes a case for hydrogen fuel cells and their role in making the transport sector greener. Speaking of greening the industry, one can make art of it as well, as detailed in an article by Hasenkamp, a specialist in art and other cultural & historical heritage logistics.

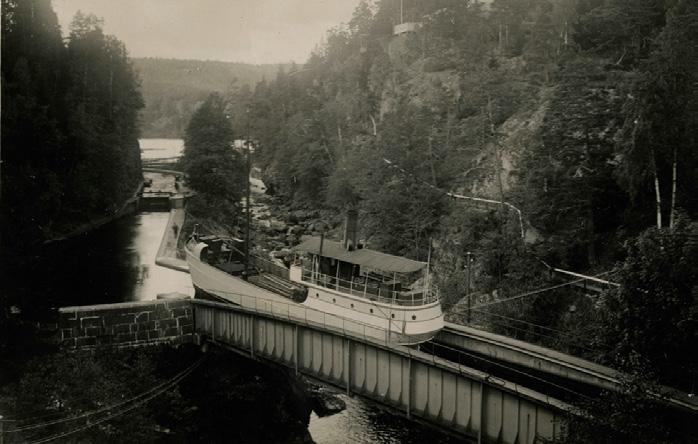

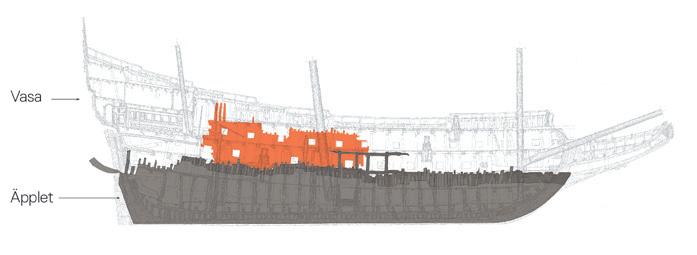

As for the Heritage corner, it, like the 5/22 edition, does proud an anniversary, this time the 190 th birthday of the Göta Canal that crisscrosses Sweden. In this Transport miscellany, we hope to give birth to a new custom, namely writing about alcohol that, this way or another, is linked to transport & logistics. Moreover, this issue’s entry on the subject ties to our other practice: reporting on the alternative uses of shipping containers.

I wish you nothing but a merry (pun intended) read!

Przemysław MyszkaBaltic Transport Journal

Publisher

BALTIC PRESS SP. Z O.O. Address: ul. Pułaskiego 8 81-368 Gdynia, Poland office@baltictransportjournal.com www.baltictransportjournal.com www.europeantransportmaps.com

Board Member

BEATA MIŁOWSKA

Managing Director

PRZEMYSŁAW OPŁOCKI

Editor-in-Chief PRZEMYSŁAW MYSZKA przemek@baltictransportjournal.com

Roving Editor MAREK BŁUŚ marek@baltictransportjournal.com

Proofreading Editor EWA KOCHAŃSKA

Contributing Writers

JARLE COLL BLOMHOFF, FRANÇOIS CHIMITS, PAUL DELOUCHE, STEVE ESAU, JACOB GUNTER, NIKOLAY GEORGIEV NIHRIZOV, ANTONIS NIKITAKIS, BEN PALMER, THOMAS THERKILD PETERSEN, GEORGIOS PLEVRAKIS, FITZWILLIAM SCOTT, GREGOR SEBASTIAN, JOHN SOUTHAM, ANDRZEJ URBAŚ, ROMAN WISST, MAX J. ZENGLEIN

Art Director/DTP DANUTA SAWICKA

Head of Marketing & Sales PRZEMYSŁAW OPŁOCKI po@baltictransportjournal.com If

LINER

EUROPE GREAT LAKES

1,600 tonnes on the move.

GreenTech for Ports and Terminals Conference , 22/02/23, DE/Hamburg, greentech.ptievents.com

GreenTech will be joining our calendar of dedicated events for C-level port & terminal representatives as our first and long-awaited live edition for sustainable, smart ports. With nearly a decade of experience hosting flagship events for Ports and Terminals, PTI is pleased to launch this platform for our community to collaborate and share knowledge which will empower ports & terminals to decarbonise and strive for net zero status in the coming decades.

Transport Week 2023, 14-15/03/23, PL/Gdynia, www.transportweek.eu

Expert speakers and a fantastic audience will once again tackle topics that shape the current face of the transport sector, from geopolitics, through market analysis to infrastructure development. Transport Week 2023 will feature the first edition of the Baltic Ports for Climate conference, organized in cooperation with the Baltic Ports Organization. The event will focus on an in-depth analysis of the progression of climate change in the Baltic Sea region, as well as showcase various climate-related projects currently underway in Baltic ports.

Container Terminal Automation Conference, 4-15/03/23, DE/Hamburg, ctac.ptievents.com

CTAC 2022 returned for its 6th edition in 2022, marking a comeback to live events for the container terminal industry. The event provided the best forum for networking, learning and knowledge sharing. CTAC will be back again in 2023, so register your interest to secure a super early bird discount before it’s too late!

Intermodal Freight Forum Europe , 11/04/23, intermodal.ptievents.com

In February 2022, PTI’s Intermodal Freight Forum Europe covered the pressing challenges and trends in intermodal freight transport – from data standardisation, to addressing the lack of capacity in ports and rail, as well as digitalisation and interconnectivity in the supply chain.

transport logistic , 9-12/05/23, DE/Munich, www.transportlogistic.de/en

The world’s leading trade fair for logistics, mobility, IT, and supply chain management has been taking place in Munich since 1978. The trade fair, accompanied by a conference programme, presents the optimal solutions for every requirement, combining innovative products, technologies, and systems with pooled expertise and a strong sales focus.

Smart Digital Ports of the Future , 16-17/05/23, NL/Rotterdam, sdp.ptievents.com

For the first time since 2019, Smart Digital Ports of the Future returned to a live, in-person event in May 2022 in Rotterdam. The event was attended by the industry’s leading innovators and representatives from the world’s smartest ports. In 2023, Smart Digital Ports of the Future will return to Rotterdam even bigger and better. Register your interest to cut a hefty discount off the event tickets when they go live.

TOC Europe 2023, 13-15/06/23, NL/Rotterdam, tocevents-europe.com/en/home

i t ’ s o u t ! i t ’ s o u t !

preview preview i

t

i t

s o u t

s o u t

’

The Port of Szczecin-Świnoujście: 26.66mt handled in I-IX 2022 (+7.5% yoy)

Tonnage-wise, the handling of liquefied natural gas (LNG) rose the most – by 885kt to 3.01mt (an increase of 41.5% year-on-year).

The Port of Szczecin-Świnoujście’s volumes [thousand tonnes]

I-IX 2022 yoy

General cargo (excl. timber), of which Wheeled (ferry) cargo 13,391.7 10,950.3 -2.0% -1.3%

Liquid bulk, of which LNG 5,015.6 3,015.2 +31.5% +41.5%

Coal 2,608.6 +21.9%

Other dry bulk 2,331.0 +4.6%

Iron ore 1,888.4 +29.9%

Grains 1,262.7 -8.7%

Timber 165.5 +53.2%

Total 26,663.5 +7.5%

Container traffic

TEUs 54,140 -15.4%

The Port of Klaipėda: 767,365 TEUs handled in I-IX 2022 (+60.7% yoy)

General cargo turnover, in total, amounted to 13.57mt, noting a yearon-year increase of 13.9%. Liquid bulk throughput also rose – by 14% yoy to 5.88mt. On the other hand, the handling of dry bulk contracted by 53.5% yoy, down to 7.67mt. Klaipėda’s January-September 2022 cargo traffic totted up to 27.13mt (-19.3% yoy).

The Port of Turku: 2.31m passengers served in I-X 2022 (+109% yoy)

On the freight side, the Finnish seaport handled 1.78mt over 2022’s ten months, down 12.5% year-on-year. International cargo traffic contracted by 11.6% yoy to 1.72mt, while cabotage by 33.5% yoy to 53.9kt. Some 88.8k trucks & trailers went through Turku’s quays (-14.7% yoy). The port also took care of 2,221 TEUs (-16.7% yoy).

The Port of HaminaKotka: 11.93mt handled in international & domestic traffic in I-IX 2022 (+8.8% yoy)

Exports totalled 8.11mt (-1.9% year-on-year), imports – 3.27mt (+24.7% yoy), while cabotage added the remaining 545kt (+601% yoy). The Finnish seaports also took care of more containers, up 2.1% yoy to 462,952 TEUs.

Finnlines: 572k ro-ro cargo units carried in I-IX 2022 (-1.9% yoy)

The Port of Liepāja: 5.65mt handled in I-IX 2022 (+11.6% yoy)

Dry bulk, the Latvian seaport’s leading trade, advanced by 10.8% yearon-year to 3.69mt. General cargo turnover came in second with 1.69mt (+29.4% yoy), followed by 236.6kt of liquid bulk (-37.4% yoy). Some 52.9k trucks & trailers went through Liepāja’s quays (+25.9% yoy) – counting 22t per one ro-ro cargo unit (the country’s average for 2021 wheeled traffic) – and 10,847 TEUs (+25.2% yoy). The Latvian seaport also served 71,512 passengers over 2022’s first three quarters (+118.2% yoy).

The company’s fleet also transported 1,084kt non-unitised freight, an increase of 4.1% year-on-year. Fewer vehicles (excluding passenger cars) were carried, down 20.2% yoy to 99k. More passengers travelled with Finnlines in January-September 2022, up 17.1% on the corresponding period last year.

The Port of Riga: 17.31mt handled in I-IX 2022 (+13.3% yoy)

Dry bulk handling rose the most – by 27.6% year-on-year to 10.41mt, followed by general cargo, which advanced by 5.5% yoy to 5.76mt. On the other hand, liquid bulk contracted by 31.6% yoy to 1.14mt. Riga’s container terminals took care of 350,093 TEUs (+13.8% yoy). The Latvian seaport welcomed 73.3k cruise travellers (vs 2,005 in I-IX 2021).

The Port of Gothenburg: 655k TEUs handled in I-IX 2022 (+6.3% yoy)

The Swedish seaport’s rail container traffic advanced even faster – by 13.2% year-on-year to 385k TEUs. At the same time, 426k ro-ro cargo units and 155k vehicles went through Gothenburg’s quays, up by 1.4% yoy and down by 18.4% yoy, respectively. Bulk turnover totted 16.68mt (+12.1% yoy), of which liquid amounted to 16.4mt (+11.6% yoy) and dry – 284kt (+55.2% yoy). Some 1.2m ferry & cruise passengers were served in the reported period (+121% yoy).

HHLA’s sea container terminals: 4,869k TEUs handled in I-IX 2022 (-5.7% yoy)

The company’s three facilities in the Port of Hamburg took care of 4,605k TEUs (-2.3% year-on-year), while the three outside Germany – the remaining 264k TEUs (-41.7% yoy). On the other hand, HHLA’s intermodal division transported more containers January-throughSeptember 2022, up 0.9% yoy to 1,266k TEUs. Rail accounted for 1,054k (+3.3% yoy) and road for 211k (-9.4% yoy).

The Port of Helsinki: 11.42mt handled in I-IX 2022 (+7.6% yoy)

The Finnish seaport’s leading trade, unitised freight, advanced by 6.2% year-on-year to 9.6mt, including 6.71mt of wheeled cargo (+8.3% yoy) and 2.9mt of containerised goods (+1.5% yoy). Helsinki also took care of 1.02mt of dry bulk (+8.7% yoy) and 702.5kt of break-bulk (+32.5% yoy). The port’s international cargo traffic totted up 11.34mt (+7.3% yoy), of which exports – 5.94mt (+3.3% yoy) and imports – 5.41mt (+12.1% yoy). Cabotage added 79.6kt (+75.6% yoy). A total of 530,499 trucks & trailers went through Helsinki’s quays (+8.3% yoy). At the same time, the port handled 365,144 TEUs (+2% yoy). Helsinki’s ferry passenger traffic amounted to 6,005,676 travellers (+156% yoy): 4,771,081 to & from Tallinn (+131% yoy), 1,050,131 – Stockholm (+741% yoy), 122,247 – Travemünde (+56.2% yoy), 32,459 – Mariehamn (-50.5% yoy), and 29,758 classified as “others” (+90% yoy). Ferries serving Helsinki’s traffic also transported 1,088,540 private vehicles (+64.9% yoy). The port welcomed 160,030 cruise guests (+2,360% yoy).

Advertisement

BTJ’s on issuu.

C L I C K H E R E T O S T A R T F L I P P I N G T H E P A G E SPhoto: Thies Rätzke /HHLA

Port Canaveral goes for a second LHM 600

Liebherr Maritime Cranes will supply the Florida seaport with a brand-new mobile harbour crane in December 2023, featuring a few tweaks relative to the one delivered in 2019. The latest addition will have a lifting capacity of 154t and a jib length of 61 metres (three more than Canaveral’s first LHM 600). Its 20-container reach will accommodate boxes stacked nine-high on the deck. The updated LHM 600 will have a redesigned cab, including a coupling of joystick and armrest to help make crane control more precise & safer as well as increase operator comfort. In addition, the manufacturer will put in place a revised air-conditioning concept to account for Florida’s hot & humid climate that can cause window fogging. “The second LHM 600 purchased by Port Canaveral is built for the future. It boasts a contemporary exterior design and is more digitally advanced and efficient. Assistance and partial automation systems are made possible by a sophisticated crane control system, evolved sensor integration, and digital information transfer,” Liebherr highlighted in a press release. Captain John Murray, CEO of Port Canaveral, commented, “We’re pleased to add this major acquisition to our port to better meet the demands of an expanding portfolio of diverse cargo. We’re projecting the pace of growth in cargo handling to be very significant over the coming year. This crane will provide greater lift capability that will also meet the needs of the developing commercial space enterprise in our region [the port’s first LHM 600 lifted a record number of boosters for space projects in the fiscal year of 2020].”

Ventplac and HHLA TK Estonia’s new Mantsinens

First, the dry bulk & break-bulk terminal operating in the Latvian Port of Ventspils has taken hold of a Mantsinen 120 mobile harbour crane. The machinery offers 92 feet of outreach and a capacity to handle up to 800t/hr (Ventplac’s leading trade is forest products such as roundwood and different grades of woodchips and pellets, as well as loose bulk goods like aggregate). Next, HHLA TK Estonia’s new gear of the 120 DER model is equipped with a diesel engine as well as electric motors. The machinery can handle up to 620t/hr of bulk goods. HHLA TK Estonia says it procures certified renewable electricity only, underlining that its new Mantsinen 120 DER is emission-free while in electric mode. “The equipment proved its high quality and operational reliability at the first use. Two ships were already serviced and loaded with 30,000 tonnes of Estonian grain and pellets each,” Riia Sillave, HHLA TK Estonia’s CEO, highlighted. She furthered, “Our new crane serves our customers faster, and with plugging it onto the shore power grid, it is the next step in our sustainability path.”

Molslinjen on the go: buys another line and battery systems

EQT Infrastructure, the Stockholm-based owner of the Danish ferry line since 2021, has entered into a definitive takeover agreement with Igneo Infrastructure Partners, who own ForSea. The transaction is subject to the approval of the Swedish and Danish competition authorities and is expected to close in early 2023. The parties have agreed not to disclose the sale price. ForSea operates on the Helsingør-Helsingborg service with five ferries (including two already and one soon-to-be electric), carrying about 6.0m passengers, 1.0m of their cars, and 450k trucks per year. “We are incredibly proud of what ForSea has become and achieved under our eight-year ownership. A global sector leader within decarbonisation, a strong and resilient business able to withstand pandemics, and a modern and reliable infrastructure operator. ForSea has a great future ahead of it,” Hamish Lea-Wilson, Partner at Igneo Infrastructure Partners, commented. Meanwhile, Molslinjen has chosen the Swedish Echandia to supply its two fully electric ferries, scheduled to enter into service in 2024, with almost 7.0MWh of battery power. “The total cost of ownership, combined with the products’ high level of safety and low weight were key factors in selecting Echandia as a battery supplier. In addition, choosing a system with a longer lifetime makes perfect sense from a sustainability perspective,” Ole Berg-Hansen, Molslinjen’s Chief Engineer, highlighted. The 116.8 m long ferries will offer room for 600 passengers and space for 188 cars. Their 3.1MWh and 3.8MWh battery systems will be charged in 20-25 minutes, respectively, with green energy. Additionally, the two will be autonomous sailing-ready, including automatic docking and charging at the quay. OSK-ShipTech has designed the newbuildings, with Cemre Shipyard putting them together. The new ferries will serve Molslinjen’s brands’ routes: Samsølinjen’s Kalundborg-Ballen and Alslinjen’s Bøjden-Fynshav.

GMP buys another batch of Kalmar machinery

The Finnish manufacturer will supply Générale de Manutention Portuaire (GMP) from the Port of Le Havre with 12 hybrid straddle carriers. The cargo handling equipment is scheduled for delivery by the end of Q3 2023, increasing GMP’s Kalmar fleet to over 50, of which 24 are hybrid straddle carriers. The order also includes a preventive maintenance contract. “Kalmar has been a trusted partner of ours for decades already, and their proven technology and commitment to developing eco-efficient solutions are a perfect fit to our sustainability targets. The hybrid straddle carrier solution will support our terminals in achieving their environmental goals while also boosting the efficiency of container moves at the same time,” Louis Jonquière, CEO of GMP Le Havre, commented. Mikko Mononen, VP of Sales, Kalmar, also said, “We are delighted to further strengthen our already excellent relationship with GMP and continue our shared journey on the road towards a more sustainable future for cargo handling operations. We are investing continuously in R&D efforts to develop more eco-efficient solutions, and we are pleased to see that our customers share the same priorities. We are also very proud that with this order, we have sold over 500 Kalmar hybrid straddle carriers globally since their introduction to the market in 2013.”

Konecranes to supply London Gateway Terminal with ASCs

The Finnish manufacturer will deliver 18 automated stacking cranes (ASCs), the first eight by Q3 2023 and the remaining ones in H1 2024. The new machinery will join London Gateway Terminal’s fleet of 60 non-Konecranes ASCs. The integration will involve replacing the existing remote operating stations and installing a new fleet management system with performance monitoring tools. “The new fleet of Konecranes ASCs will be equipped with Konecranes’ in-house automation technology across the board. This will include automated handling of road trucks. This is based on Konecranes’ routine calibration-free solution, which enables steady hit rates over time, reducing the number of exceptions that the remote operator must handle,” Mattias Karlsson, Konecranes’ Sales Director of Port Solutions, said. He added, “The new fleet management system will be implemented for both the non-Konecranes and the Konecranes ASCs, harmonising remote operation across the ASC fleet.”

Gävle to grow with a cement terminal

SCHWENK Sverige, the Swedish company of the German SCHWENK Building Materials Group, has signed a 25-year lease agreement with the Port of Gävle. Following the deal, SCHWENK Sverige will set up a 90kt/year capacity terminal on Quay 1. Construction works should start in Q1 2023, with the first cement shipment arriving by year-end.

Färjerederiet’s biggest investment ever – inked

The Swedish Transport Administration’s ferry company has commissioned the Holland Shipyards Group to construct four hybrid ships. The 86 by 14.2 m domestic traffic ferries, which will serve Stockholm’s archipelago, will be delivered starting from summer 2024 one piece a year. The newbuilds, usually running on electricity, will also feature backup HVO diesel engines. The entire investment (totalling SEK1.0b) will also cover eight automooring installations, four charging stations, a simulation centre likewise one for

operations automatically (autonomy

for vehicle load- and unloading. The

help realise Färjerederiet’s

V E R Y B O D Y D E S E R V E S A T R E A T ! E V E R Y B O D Y D E S E R V E S A T R E A T ! E N D / S T A R T T H E Y E A R E N D / S T A R T T H E Y E A R

I T H Y O U R V E R Y O W N X L M A P ! W I T H Y O U R V E R Y O W N X L M A P !

Auto Achieve reaches the Baltic

UECC’s latest hybrid gas-run car carrier has berthed at the Port of Gothenburg, where she received her name and joined the weekly service that links the Swedish seaport with Zeebrugge, Drammen and Esbjerg. The 169 by 28 m ship can carry up to 3,580 vehicles across ten decks. Auto Achieve joins her sister ships, Auto Advance and Auto Aspire, constructed by Jiangnan Shipyard and christened in Zeebrugge in October 2022. The company says that the trio exceeds the International Maritime Organization’s (IMO) requirement for a 40% reduction in carbon intensity by 2030. “With new IMO carbon intensity regulations just around the corner and the looming prospect of higher costs for using conventional marine fuel, we are convinced that our timely investments in these newbuilds will make a real difference for the environment and for business. That is called sustainability progress,” Glenn Edvardsen, UECC’s CEO, commented.

LTG Cargo tests a new north-south rail corridor

The Lithuanian rail freight haulier is trialling the feasibility of connecting the country with northern Italy via Duisburg. The test run saw trailers sent from Kaunas to Cervignano near Trieste through the German dry port. Once regular, the service will run twice a week.

Color Line’s two vessels on sale

The Norwegian shipping line removed the Color Viking ferry from the Sandefjord-Strömstad service and the Color Carrier ro-ro from the Kiel-Oslo one, putting them up for sale. The company says that high energy prices, macroeconomic uncertainty, and worsened framework conditions had led to the decision. Color Line adds that other factors came into play, too: halving the tobacco quota for residents of Norway as well as reducing the allowance scheme for Norwegian seafarers in the country’s budget for 2023. Color Carrier embarked on her last journey in Color Line’s livery on 14 November 2022, while Color Viking – six days later. The Color Hybrid ferry continues to serve the Sandefjord-Strömstad crossing.

Viking Line buys into Eckerö

The Ålandic company has purchased 17.1% of shares, for nearly €10.3m, of the Finnish holding also located in Mariehamn on the Åland Islands. Viking Line has carried out the transaction with its own funds. Commenting to Ålands Sjöfart, Viking Line’s CEO Jan Hanses did not reveal whether the two companies will merge. He underlined that the share buy was done to keep Eckerö’s stock on Åland. The Eckerö Group comprises a few shipping lines that operate in the Baltic, including the Helsinki-Tallinn, Vuosaari-Muuga, and Eckerö-Grissleham ro-pax services. The Group’s Eckerö Shipping disposes of a fleet of three ro-ros. Eckerö also holds the Birka Cruises brand, the operations of which were terminated in 2020 due to the coronavirus pandemic (the company’s Birka Stockholm has been laid up since that time and is up for sale).

TSG takes in another container ship

Thor Svecon Group (TSG) chartered the 1995-built, 133 by 19 m, 660 TEUs capacity Perseus, which the company deployed on the NorvikRotterdam-Hull service on 8 November 2022. “We have seen the need for a fourth vessel for some time, and now that time has come. Starting from Sweden’s newest port, Stockholm/Norvik, feels like a natural step and completely in line with our goal to strengthen our position in east coast shipping,” Eric Hjalmarsson, TSG’s CEO, said. Lawrence Yam, Hutchison Ports Stockholm’s CEO, added, “The extended connectivity from Stockholm/Norvik to Rotterdam is going to provide our customer more options and even more flexible and faster transit to the major hub port in Europe. A direct linkage to Rotterdam would enable connectivity to new services and to different parts of the world. We are very happy to see that SUN Line [TSG’s brand] is seeing the benefits of starting up a new service that will give their customers the fastest transit to the Greater Stockholm Area.” TSG also runs the Mälar-Benelux & Hull network, connecting the ports of Västerås, Södertälje, Oxelösund, Antwerp, Hull, and Amsterdam. Three vessels serve it: Alrek (360 TEUs), Frej (304), and Odin (304).

New intra-Germany intermodal service

Hector Rail and Samskip have launched the thrice-a-week Duisburg-Rostock connection for containers and trailers (including non-cranable). The 700 m long trains link Duisburg Hohenbudberg and Rostock Trimodal. Arrivals at the latter are synchronised with Hansa Destinations’ ro-ro service between the German seaport and the Swedish Nynäshamn. “There has been a clear need to increase capacity between Germany and Scandinavia based on growing trade volumes and new requests, but high diesel prices and continuing driver shortages are also steering more cargo away from the road,” Gert-Jan Meijer, Head of Trade, Sweden, Samskip, said. He furthered, “Offering an additional high-frequency service option consolidates the competitive edge that multimodal has over

chain.” Meijer also underlined, “Our larger customers want to do more using

door, and it’s fair to say that there is a general mood in Germany

New sea container service between the Baltic and North seas

Containerships has launched a weekly loop that links the ports of Bremerhaven, Gdynia, Gävle, Klaipėda, and Wilhelmshaven. The new service will also take care of 45’ containers. From Gävle, Containerships offers intra-Sweden haulage by road and rail.

EBRD-COM circumventing Russia rail study

The European Commission (COM) is funding an analysis carried out by the European Bank for Reconstruction and Development (EBRD) on identifying the most sustainable transport connections between Central Asian economies and the extended Trans-European Transport Network (TEN-T) of the EU. The study, set for completion by the summer of 2023, will also include action proposals, such as where infrastructure investments should go. The study aims to enable the Middle Corridor to take over the volumes thus far transported through Russia and Belarus along the Northern Corridor of the New Silk Road. EBRD estimates that some 80k TEUs will follow the Middle Corridor this year, close to its max capacity of 100-120k. In contrast, the Northern Corridor saw 1.5m 20’s between Far East Asia and Europe in 2021. “A diversion of transit cargo exceeding 10 per cent of the Northern Corridor’s tonnage will require large investment across the entire corridor, and its economic efficiency is yet to be assessed. The EBRD estimates immediate investment needs for Middle Corridor infrastructure upgrades to be in the region of €3.5 billion,” the organisation said in a press release. The initial findings point to several key challenges standing in the way, including high tariffs, insufficient sea shipping capacity and irregular shipping networks, port performance inefficiencies, lack of international agreements, shortage of European contacts in Central Asia, non-electrified railroads, rolling stock in need of modernisation, and the Caspian Sea being not always navigable. “Eventually, the success of the Middle Corridor will depend on the ability of all countries along the route, including Kazakhstan, to work seamlessly, eliminate trade barriers and set up regular and reliable freight schedules. If the Middle Corridor is to become a viable transportation alternative, it must offer a predictable and reliable environment for all parties involved,” EBRD summed up.

New China-Poland e-commerce & postal rail service

Xi’an Free Trade Port Construction and Operation has linked Xi’an and Małaszewicze with a 12-day transit time service that carries e-commerce parcels & international letters. In Poland, the shipment is taken over by Polish Post for onward distribution throughout Europe.

Third rail terminal between China and Kazakhstan

Shahrat Nureshev, the Kazakh Ambassador to China, has revealed that a third rail border crossing will be added to handle containerised freight passing between the two economies as well as in transit to and from Europe. The new facility will be in Tacheng in the Ili Kazakh Autonomous Prefecture. However, no more details were presented. The Tacheng terminal will join Alashankou and Khorgos, which handle 90% of China-Kazakh rail cargo.

COSCO drops its DGT shares

The Chinese have sold their 30% stake in Duisburg Gateway Terminal (DGT) to duisport, the dry port’s authority. The deal was already cut in June 2022, but the news bit kept hidden until late October. The €100m-worth DGT is an investment launched in 2019 by duisport and COSCO (each holding 30% of the project’s shares), with the help of HTS and Hupac (the remaining 40% split in half). The brownfield multimodal project, to be erected on Duisburg’s coal island, will span 235k m2 and comprise 12 rail tracks (730 m long), three barge berths, and 60k m2 of container depot plus a further 20k m2 reserved for warehouses. The facility’s handling capacity is estimated at 800-850k TEUs/year, taken care of by six gantries. DGT is scheduled to come online in mid-2023. Construction works kicked off this March.

New China-Italy rail service

Before November 2022’s end, Hupac had started connecting Xi’an and Milan. Transit time amounts to 25-28 days. The service’s trains cross the Chinese border in Manzhouli, running on their way to Italy via Russia, Belarus, Poland, Germany, and Austria.

The 2022 CEF Transport Call

A total of €5.12 billion has been made available under the newest Connecting Europe Facility (CEF) call for proposals. The single-stage deadline is set for 18 January 2023. The envelope includes €1.62b (general) and €2.0b (cohesion) for TEN-T Core Network projects, €250 & €350m for projects on the TEN-T Comprehensive Network, €400m and €150m for smart and interoperable mobility, €1.2b and €375m for alternative fuels infrastructure, €100m for sustainable and multimodal mobility, €100m and €150m for safe and secure mobility, and €330m for adopting the TEN-T to civilian-defence dual use (the MilMob call, launched on 12 May 2022, has received 63 projects requesting over €1.3b; their evaluation process is expected to be concluded by the end-December 2022).

EMSA reports on alternative fuels

The European Maritime Safety Agency (EMSA) has updated its report on the potential of biofuels in shipping and released its analysis of ammonia as marine fuel. These reports aim to support the European Commission in the ongoing work on the Fit for 55 package, particularly on the FuelEU Maritime proposal. “As a ‘drop-in’ fuel which could replace conventional fossil fuels without substantial engine modification, biofuels can offer an immediate alternative for the existing fleet. The report finds that many of the existing maritime regulations can be transferred from fossil fuels to biofuels, and the safety risks are broadly similar. However, the research notes that the future availability of sustainable biofuels may be in question, given the size of any potential demand from the maritime sector,” says EMSA. On the latter, the organisation commented, “Based on the growing interest for ammonia-fuelled vessels and in projects to produce green ammonia, the report concludes that ammonia is likely to transition to a marine fuel which could enter the market quickly and offer a zero or near-zero carbon solution. However, despite the maritime sector’s extensive experience in handling ammonia as cargo, there is currently little accumulated industry knowledge in its use as a fuel, indicating a need for further understanding of the potential safety-related risks and other challenges it poses. In addition, the study has identified a number of barriers to the widespread deployment of ammonia, including access to renewable electricity for its green production, and technology and regulatory gaps which could prevent its immediate application.” Maja Markovčić Kostelac, EMSA’s Executive Director, summed up, “The reports [...] are just a first step in our research into the potential of different alternative fuels and power solutions, and form part of the support we provide at this critical moment in the maritime sector’s voyage towards decarbonisation. Throughout our work, we keep the safety aspect of alternative fuels firmly in our focus, as the transition to true maritime sustainability can never be complete without the safety dimension.”

Pre-combustion carbon capture

The American Bureau of Shipping (ABS) has issued a new technology qualification for a pre-combustion carbon capture system (based on the thermocatalytic decomposition, TDC, process) developed by the Norway-based hydrogen company Rotoboost. The company’s TCD allows for continuous hydrogen production and carbon capture onboard marine vessels by converting natural gas into hydrogen and solid carbon with a liquid catalyst. The resulting gas can be used for fuel cells or as a blend-in fuel for combustion engines or gas-fired boilers. The process can reduce overall carbon emissions by up to 100%, depending on the heating method. In addition, the two say, using hydrogen as a blend-in fuel promises to significantly reduce the methane slip from combustion engines and reduce particulate matter emissions by capturing carbon in solid form before combustion. “Decomposing methane into hydrogen and solid carbon is an intelligent way to implement a carbon capture and storage solution onboard gas-fuelled ships. This method reduces the storage need onboard, and the solid carbon can be used in the production of fuel cells and batteries and can be recycled again and again. This technology is one that promises to accelerate the energy transition, supporting global decarbonization goals,” Georgios Plevrakis, VP of Global Sustainability, ABS, highlighted. Kaisa Nikulainen, Rotoboost’s CEO, added, “The system can be scaled up modularly step-by-step to meet progressing emission regulations while being cost-effective for shipowners compared to green fuels or conventional carbon capture systems.”

The Green Shipping Challenge

Responding to the Green Shipping Challenge formulated by Norway and the US in May 2022, several Norwegian organisations from across shipping, business, class, and finance have teamed up to make the maritime sector zero-emission. Participants in the Norwegian collaboration will strive towards halving shipping’s footprint by 2030, in line with Norway’s climate goals. Alongside efforts to improve existing vessels’ energy efficiency, the partners undertake to develop, design and build future eco-friendly ships. According to them, achieving the 2030 national climate target will require 700 lowand 400 zero-emission ships in Norway alone. The partnership involves GCE Blue Maritime, NCE Maritime CleanTech, the Confederation of Norwegian Enterprise, the Federation of Norwegian Industries, the Norwegian Shipowners Association, Norwegian Coastal Shipowners, Maritimt Forum, Havila Voyages, Hurtigruten, Kongsberg, and DNV. Norwegian financial partners with maritime patronage will utilise capital instruments to support green measures and projects by providing risk capital and financial advisory services in line with regulatory requirements and expectations. “Norwegian government support for green initiatives and infrastructure development for fossil-free energy sources will also play a key role,” the parties have said in a press release.

OFFSHORE HYBRID ENERGY PARK

• The Dutch-Norwegian company SolarDuck will erect a 5.0MW offshore floating solar farm as part of RWE’s 760+MW Hollandse Kust West (HKW) VII offshore wind energy investment. The project will become operational in 2026. In mid-July 2022, RWE and SolarDuck signed a collaboration agreement to develop floating solar parks. Specifically, to accelerate the learnings on SolarDuck’s floating solar technology, RWE agreed to invest in the first offshore pilot in the North Sea. “This is a flagship project for SolarDuck and an important milestone for the wider OFS [offshore floating solar] industry. SolarDuck, being the first to build a hybrid project

at this scale, will demonstrate the robustness of our solution, prove the important role of system integration in building future-fit energy systems, and enable the scaling of the technology to accelerate its adoption,” Koen Burgers, SolarDuck’s CEO, commented. In October 2022, SolarDuck announced it would partake in a joint industry project (24 partners, five observers) to standardise and develop regulations and guidelines for offshore floating solar energy. The HKW VII site is located in the North Sea, about 53 kilometres off the Netherlands’ coast. Once up & running, the farm will produce enough energy to supply almost one million Dutch homes. •

SAMSKIP TO CONTINUE SAILING ON BIOFUELS

• The shipping line has extended its agreement with GoodFuels, committing its four container vessels to carry on running on the latter’s MDF1-100 biofuel. Samskip’s Endeavour, Innovator, Hofell, and Skatafell will sail on the biofuel formulated from sustainable waste streams (from the EU’s Renewable Energy Directive list; the product also holds the International Sustainability and Carbon Certification). According to Samskip, sailing on GoodFuels’ MDF1-100 will result in 45kt CO2 savings by 2022-end. “Sustainable marine biofuels offer a viable way for Samskip to cut CO2 emissions by 90% so that our ships and freight customers reduce their carbon footprint in the interests of the planet. It would take the equivalent of 1.7 million trees to offset this amount of CO2 emissions,” Erik Hofmeester, Samskip’s Head of Vessel Management, said. He furthered, “As part of Samskip’s relationship with GoodFuels, freight owners also become part of a scheme where the lower ocean carbon footprint is auditable as carbon credits in the supply chain.” Following biofuel trials in 2019, Samskip began routinely running main engines on board the 800-TEU Samskip Endeavour as part of services between the Netherlands and Ireland. The company included

Innovator on the Netherlands-UK service last year before adding Hoffell and Skatafell on the Iceland-UK-Netherlands route in 2022. Bunkering for all four ships takes place in Rotterdam. “Initially using a biofuel blend which achieved a 30% CO2-reduction, more competitive pricing enabled Samskip to integrate a 100% biofuel from 2021 and achieve the 90%-reduction,” said the company in a press release. Max Verloop, Marketing Lead at GoodFuels, also shared, “Verifiable performance is proving to be a key advantage for sustainable marine biofuels as a drop-in replacement for conventional oils. Clearly, several solutions are required to decarbonize shipping overall, but biofuels are proving their case on scalability – one of the key challenges facing any low carbon fuel alternative.” The two parties also underlined in a joint statement, “In June, IMO’s Marine Environment Protection Committee published a new ‘Unified Interpretation’ which makes the first explicit acknowledgement that marine biofuels satisfy the requirements of MARPOL (The International Convention on Marine Pollution).” Negotiations are already underway covering a 2023 supply contract, with one scenario on the table extending the agreement to chartered vessels. •

HHLA HANDLES AMMONIA

• The first test shipment of ammonia was brought in a tank container on board one of Hapag-Lloyd’s vessels to HHLA’s Container Terminal Altenwerder (CTA) in Hamburg. The delivery results from the March 2022-signed agreement between HHLA and Abu Dhabi National Oil Company, wanting to test the hydrogen supply chain from the United Arab Emirates to Germany. The ammonia will be used by the Hamburgbased company Aurubis for test runs for the climate-neutral conversion of gas-intensive copper wire production. More ammonia deliveries will be shipped to other customers in Germany in the coming months.

“We at HHLA are very proud to be part of the joint, successful development of a secure supply chain for hydrogen carriers from the United Arab Emirates to Germany. In order to use hydrogen and its derivatives as an energy carrier on a large scale in the future, we need a reliable, climate-neutral and efficient transport chain from the producing countries such as the United Arab Emirates to the German and European customers,” Torben Seebold, Member of HHLA’s Executive Board, commented. HHLA says its CTA is climate-neutral, meaning that this part of the ammonia supply chain adds no emissions. •

CIRCLE K’S E-TRUCK CHARGING STATION OPENS IN GOTHENBURG

• The facility offers six public charging points for heavy-duty lorries, with each bay providing up to 360kW of power. There is room for adding more bays (even 1.0MW). Apart from the bays, the facility offers a fenced, CCTV parking lot for about 40 trucks. The station also comprises amenities (showers, toilets, and food & drinks). Within one year, it will be possible to tank hydrogen at the station (720 kg of capacity, one bay, 15 trucks/day). “The station’s opening at exactly the right place, in terms of both timing and location. Serial production of electric heavy goods vehicles is up and running, and vehicles have been ordered by actors with a lot of traffic at the port. By the end of the year, electric heavy trucks will be a common sight in the port, and it will just keep on growing from there. So, this

station comes at just the right time – the transition is taking place here and now, and as far as the port is concerned we’re delighted to be able to work with Circle K to provide the necessary infrastructure,” Elvir Dzanic, the Gothenburg Port Authority’s CEO, commented. Lennart Olsson, Senior Manager Pricing at Circle K Sweden, also said, “The station is a magnificent flagship and a real milestone along the way to a future of greener transport operations. We’re incredibly happy and proud to be leading the way on this journey and of what we’ve achieved, such as the collaboration with the port. The station’s strategic location and smart structure mean that we’re well-prepared for the market’s future needs for different fuels. This station has the potential to become an important hub in the transition.” •

European

A big (cruise) fish in a small pond

by Marek BłuśIf 2020-end left Baltic shipyards with any dreams of blossoming, the beginning of this century’s third decade buried all hope of turning the region into a multi-yard cruise ship construction hub. Whereas the 2021 production measured in gross tonnage (GT) grew by about 10%, two other crucial figures did not change much: handed over vessels and shipyards counting new deliveries – 24 and 11, respectively (read: stagnation). As usual, some names disappeared from the shipbuilding list: Flensburger Schiffbau-Gesellschaft (FSG), Pella and Yantar, while others joined the rooster: Admiralty and Safe (both back after four years of absence) as well as MV Werften, which was our greatest hope but proved to be nothing more than a flash in the pan.

and Baltic shipyards’ performance in 2021 Baltic

Tab. 1. Vessels GT 100 and above built by Baltic shipyards in 2021 – in gross tonnage order

Name Flag GT Shipyard Type

Costa Toscana Italy 186,364 Meyer Turku Pax (cruise)

Sibir Russia 28,494 Baltic Icebreaker

Aurora Botnia Finland 24,036 RMC Ro-pax

Crystal Endeavour1 Bahamas 20,449 MV Werften Pax (cruise)

SH Minerva Malta 10,617 Helsinki

Salish Heron Canada 8,728 Remontowa Ferry2

Gali

For the second time in a row – and the third time in Baltic shipbuilding history – a single delivery accounted for over half (56%) of the annual production. We are witnessing the birth of a new custom: the same phenomenon occurred in 2022 and is expected to hold in the coming years. The Finnish subsidiary of the German Meyer Werft advances by leaps and bounds – from GT 100k in 2019 to over GT 180k last year, dominating the regional output with one hand tied behind its back. The yard’s position will only solidify in the near future: Royal Caribbean International’s (RCI) order of the Icon of the Seas will get Turku’s production over GT 200k in 2023, up to more than GT 300k in 2024 thanks to two deliveries for RCI and TUI. Turku’s Costa Toscana was also the biggest ship built in Europe last year, ahead of another of Meyer’s GT 180k+ ‘sailing hotels,’ AidaCosma.

And here is where the good news from the cruise sector ends. MV Werften delivered its first – and last – GT 20k cruiser (called a “megayacht”), leaving the bankruptcy trustee with a single unfinished hull of GT 200k (the ship will be completed for Disney Cruise Line, probably in 2025). Although Helsinki Shipyard (former Arctech) wrapped up two expedition cruisers year after year, the company found itself in trouble following contract cancellation for a third and final cruiser in the series, and, additionally, because of the export licence withdrawal for an icebreaker ordered by the Russian company Norilsk Nickel.

The pure freight sector reached its historical bottom in 2021 by delivering two small general cargo ships constituting 2.8% (GT 9.5k) of the whole Baltic output. If the delivery of Tennor Ocean by FSG is postponed – a round zero will be floated out in 2022. FSG, the leading European maker of ro-ro ships, disappeared from the 2021 delivery list due to its insolvency and restructuring.

On the other hand, there is nothing fishy about the part of the shipbuilding industry that offers solid hope, namely fishing. The sector is dominated by a single builder: Karstensen. Among the 24 deliveries in 2021, ten were fishing vessels, with Karstensen putting together eight. The company from Skagen has 16 ships in its order book. The yard’s ‘hull factory’ (Karstensen Poland) will move in 2023 from Gdynia, located there since 2018, to the historic site of the former Stocznia Gdańska (lately Nauta) – to the area used in the 19 th century by Schichau-Werke from Elbląg to erect its second plant.

Tab. 2. Vessels GT 100 and above built by Baltic shipyards in 2022 – in gross tonnage order (provisional)

Name Flag GT Shipyard Type

Carnival Celebration Panama 183,521 Meyer Turku Pax (cruise)

MyStar1 Estonia 50,629 RMC Ro-pax Tennor Ocean1 Malta 32,770 FSG Ro-ro Ural1 Russia 28,476 Baltic Icebreaker

SH Vega Panama 10,617 Helsinki2 Pax (cruise)

Severniy Polus Russia 9,843 Admiralty Research Kapitan Vdovichenko 9,055 Fishing Astrid Denmark 4,697 Karstensen Artemis UK 3,215 Altera Finland 1,399 CRIST Ferry Myggenes Denmark 600 Karstensen Fishing Monsun Norway 498 Strażak-28 Poland 368 Remontowa Firefighting

Total 335,688

1 Delivery expected in December 2022

2 Former Arctech

Tables 1 and 5 can raise doubts because of two seemingly lacking deliveries – the Russian sister ro-paxes Marshal Rokossovky (GT 20,661) and General Chernyakhovsky (GT 20,724). Nevsky Shipyard was indeed their contracting firm. Still, both were built by the Turkish Kuzey Star and travelled to St. Petersburg without tug assistance. It means that the two were outfitted

and equipped with all the viable systems in the South. At their homeport, a brass plate with the shipyard’s name should only be attached to the front of the bridge, plus some minor jobs carried out. As such, our lists assign the ships to the yard that completed the drive and other systems required by regulations for safe, independent navigation.

Europe

Cruise ships, totting up to 65% of the GT delivered from the Baltic in 2021, were even more important for Europe’s shipbuilding: 17 vessels in total, +23% in GT to 70% of the continent’s output (vs 13 cruisers and 68% of market share in 2020). In Italy, cruisers constituted 93% (!) of all GT, Germany – 99% (!!), France – 97% (!!!), Finland – 89%, and Norway – a “mere” 51%. Production was concentrated in two industrial groups: Fincantieri delivered GT 544k from its Italian and Norwegian (the Vard brand) yards, and Meyer made GT 538k from its German and Finnish plants.

Italian production was complemented, so to say, by the ro-pax GNV Bridge (GT 32,581) from Visentini Shipyard. Although a domestic service ferry, it would rank as Europe’s 10th biggest in 2021. Other notable mentions include three non-cargo carrying vessels: the cable-layer Leonardo da Vinci (GT 27,937) from Vard, the polar icebreaking research and supply ship Nuyina (GT 22,867) built by the Dutch conglomerate Damen for Australia, and the mining vessel Benguela Gem (GT 20,503) – also from Damen but for the diamond industry in Namibia.

Even as European deliveries grew by 19% in 2021, the output was still below the two million GT mark, accounting for some 3% of global completions. Where are deglobalisation and homeshoring when Europe’s shipbuilding industry needs them?

Tab. 3. European shipbuilding countries’ performance in 2020-2021 (thousand gross tonnage)1

No Country 2021 2020 yoy 2021 order book 2

1 Italy 501 518 -3.3% 3,100 2 Germany 374 309 +21.0% 1,623 3 Finland 221 182 +21.4% 1,100 4 France 188 138 +36.2% 1,060 5 Norway 175 102 +71.6% 70 6 Netherlands 125 121 +3.3% 200 7 Russia3 107 131 -18.3% 150 8 Spain 71 46 +54.3% 300

9 Romania 44 – – 200

10 Poland 24 13 +84.6% 160 11 Croatia 23 15 +53.3% 200

12 Denmark 21 9.0 +133% 32 13 UK 18 7.0 +157% 15 14 Portugal 10 10 +/-0% 50 15 Greece 4.0 1.0 +300% 4.0 16 Bulgaria – 3.0 -100% 6.0

Total 1,906 1,605 +18.8% 8,270

1 Statistic based on the location of the contracting/outfitting shipyards 2 At the end of the year 3 Shipyards in the European part of the country only Sources for Tabs. 3 and 5: national and associations’ statistics corrected by own research

Tab. 4. Cruise vessels built by European shipyards in 2021 – in gross tonnage order

Name GT Shipyard Owner/operator

Costa Toscana 186,364 Meyer Turku Costa Crociere

AidaCosma 183,774 Meyer Werft Aida Cruises

MSC Virtuosa 181,541 Chantiers de l’Atlantique MSC Cruises

MSC Seashore 170,412 Fincantieri

Odyssey of the Seas 167,704 Meyer Werft Royal Caribbean

Tab. 5. Top 10 shipbuilding countries in the world in 2019-2020 (million gross tonnage)

No Country 2021 2020 yoy 2021 order book1

1 China 26.91 23.25 +15.7% 77.00

2 South Korea 19.70 18.48 +6.6% 57.00

3 Japan 10.70 12.94 -17.3% 19.50

4 Philippines 0.63 0.61 +3.3% 1.64

5 Italy 0.50 0.52 -3.8% 3.10

6 Germany 0.37 0.31 +19.4% 1.62

Valiant Lady 108,192 Fincantieri

Virgin Voyages

Rotterdam 99,935 HAL

Viking Venus 47,842

Viking Ocean

Silver Dawn 40,855 Silversea

Le Commandant Charcot 31,283 Vard Ponant

Viking Octantis 30,114 Viking Ocean

Crystal Endeavour 20,044 MV Werften Silversea

Hanseatic Spirit 15,651 Vard TUI Cruises

Ultramarine 13,827 Brodosplit V Ships Leisure

National Geographic Resolution 12,786 Ulstein Lindblad Expeditions

SH Minerva 10,617 Helsinki1 GTLK Europe

Golden Horizon 8,784 Brodosplit Brodosplit-Plovidba

Total 1,330,130

1 Former Arctech

7 Vietnam 0.37 0.58 -36.2% 0.97

8 Finland 0.22 0.18 +22.2% 1.10

9 Taiwan 0.20 0.32 -37.5% 0.22

10 France 0.19 0.14 +35.7% 1.06

Total Top 10 59.79 57.33 +4.3% 163.21

Total world 60.60 57.80 +4.8% 172.37

1 At the end of the year

A dinosaur industry not willing to bend – for all the wrong reasons

Like it or not

by Ewa KochańskaStatistics from western countries, and recently also globally, highlight that female students regularly outnumber their male counterparts in higher education institutions. Women are progressively making their way into industries previously viewed as ‘male-only,’ taking over positions that men are increasingly not qualified to fulfil. However, despite growing opportunities for females in the maritime industry, the sector still has one of the least gender-diverse workforces in the world. The second instalment of the Gender Diversity Booklet. Heading towards an inclusive work culture – prepared by Anglo-Eastern Maritime Training Centre in cooperation with Women’s International Shipping & Trading Association, the International Seafarers’ Welfare and Assistance Network, and the International Chamber of Shipping – dives into the reasons why women still struggle to establish themselves on the seas. The findings are based on data gathered via an online survey of active female seafarers who gave their opinions on attitudes, discrimination, and harassment in the maritime industry.

The survey for the latest Gender Diversity Booklet included female maritime workers from 78 countries, 90% of whom worked on cruise ships, with the remaining employed on various freighters (such as tankers, container, off-shore supply vessels, and other general cargo). The 1,128 respondents gave examples of their experiences of sexual misconduct, bullying and gender stereotyping, as well as undesirable working conditions and poor access to female-specific healthcare.

Because I’m a female

According to research, a diverse workforce leads to better problem-solving and decision-making by bringing in various viewpoints, abilities, and experiences. Such an environment leads to higher worker engagement and reduced employee

turnover, improving the company’s reputation as well as its productivity and profitability.

However, a study by Harvard Professor Letian (LT) Zhang of leading companies from 24 industries in 35 countries shows that gender diversity makes companies more productive only as long as there is a “widespread cultural belief” that gender diversity is important. This is why the maritime industry must take steps as a sector to diversify its workforce and change its culture to start reaping full benefits from female engagement at all levels.

The Gender Diversity Booklet survey results show that the main challenges female maritime workers face include discrimination, harassment, bullying, isolation, and a fixed mindset. For women, discrimination is frequently their first experience in maritime during the

recruiting process. Females reported being scrutinised for their perceived physical inaptness, lack of leadership experience, or for having to balance family and work life.

Further, many responses highlighted mental harassment cases. Examples given by female seafarers working on non-cruise ships included being told not to leave their rooms after 9 pm or to wear only “certain type of clothing” around their male counterparts. They are also being given cutesy nicknames or called “dear” and “honey” (while male officers go by their actual names). A second officer on board a bulk carrier recalled: “I can’t socialise with the crew without facing a mixture of harassment. Males assume that I’m sleeping with someone I have good conversations with. This creates friction on board and constant harassment. If I make any mistake, everyone assumes it’s because I’m a female.”

A third engineer on board a chemical tanker : “Although I have experienced this in my early sailing period when I was junior, the machinery overhaul jobs and tasks were not given to me. I was told to stay in the engine room, fill the engine room log book and check the parameters. Seniors were not very confident of my ability and they used to accompany me every time to see whether I could complete the task. I was asked to arrange the control room as they assumed being a girl I know how to keep things tidy and neat. I was asked to make coffee for seniors all the time in the breaks. Chief Engineer, in fact, called me once to his cabin and asked for a cup of coffee which I declined saying that I was doing some work in the engine room.”

companies continuing to hesitate to hire and promote women is directly related to their fixed mindsets about gender roles; jobs such as sailing, particularly on non-cruise vessels, are still considered an occupation reserved

All of these issues experienced by female seafarers can lead to “anxiety, poor sleep, depression, loss of appetite, headaches, exhaustion or nausea. Victims feel humiliation, mistrust, anger, fear and sadness,” states the Gender Diversity Booklet

have to deal with poorly fitting personal protective equipment, possibly causing severe injury. This situation also conveys that women’s safety and well-being are unimportant to the company.

Similarly, working conditions on board ships leave women seafarers lacking. In particular, the Gender Diversity Booklet highlighted the need for separate toilets for women near the work area, which are clean and well-lit, with locks and proper waste bins. A female seafarer on a cruise ship described having only one bathroom for women near the crew mess but far from the working area, while her male co-workers had several bathrooms nearby.

Access to personal hygiene products, as well as disposal bins for sanitary waste, can also be an issue on ships. A third officer on board a gas tanker described: “I ended up doing a longer trip, and I asked if they would supply sanitary products to female seafarers unable to disembark due to COVID-19.

cal form) is also a major issue for women seafarers. One example cited in the survey results was from a third officer on board a tanker: “I have been told that women are only meant for bed, bearing children and not fit to work on ships. I have faced many situations where my opinion wasn’t taken. I have been policed for talking or being ‘extra friendly’ with people who were batchmates or just workmates.”

Bullying and cyberbullying can be problems as well, showing up as repeated harassment in the form of hostile or vindictive behaviour, in person or online, causing the victim to feel threatened or intimidated.

Additionally, the feeling of isolation in the maritime sector is a critical factor that works against women. While many maritime organisations have aggressive recruiting programmes for female seafarers, the survey respondents said that, especially when starting, they felt ignored, their capabilities were constantly questioned, and they had to work extra hard to prove themselves.

Nevertheless, the survey respondents stated that in many instances, with time, their male colleagues started accepting and appreciating them. The challenges women in the maritime sector face often involve a fixed mindset of people in charge, not those they interact with daily. While acceptance of women in maritime is on the rise, “research shows that there is a reluctance to promote women to senior positions,” showing stereotypical thinking from the senior-level leadership. The issue of shipping

Women often try to alter their own behaviour to avoid, for example, harassment and bullying, while the harassers continue with their everyday routines. Discrimination causes stress and low self-esteem, which can lead to depression and a nervous breakdown. Harassment and bullying on the ship can quickly result in victim withdrawal and loss of commitment to their job and ship.

Considering these situations’ mental and physical load, female seafarers are at a higher risk of physical accidents. Another serious consequence of working in such a male-dominated and stressful environment is that some women in the maritime industry showed their own unconscious bias, believing that some jobs were better suited for men than females due to these genderrelated abuses.

Unprepared

The challenges of working in a male-dominated industry such as maritime are not only psychological. Often these sectors are ill-prepared in terms of equipment to accommodate women. For example, females at sea

The male office staff asked me to repeat my question as this

A second engineer on board a bulk carrier: “On my first ship the Chief Engineer came down during the night rounds with the 2/E, drunk, as usual and tried to hold me by the waist while I was filling the log book.”

Poorly Fitting Personal Protective Equipment

issue obviously hadn’t occurred to anyone. Whilst they said they would look into it, sanitary products never arrived.”

Access to healthcare providers able to handle female medical issues has also been a challenge. The Gender Diversity Booklet advises that a medical officer trained to address female health challenges is a must on board ships. The employer also needs to provide medical confidentiality, easy access to a shore specialist for a second opinion, and job security in assuring that even if on medical leave, the seafarer will be rehired once the issue is resolved.

This leads straight into a discussion about maternity constraints, a loaded topic in almost every industry. One of the main reasons why women do not consider a career as a seafarer is balancing career and motherhood. Allowing for shorter contracts and having a clear maternity leave policy could alleviate some concerns. “Paid maternity leave is a core element of the health and economic protection of women workers and their children over the perinatal period. A vast majority of countries have adopted statutory provisions for paid maternity leave. This entitlement is associated with positive health outcomes for women and their children (ILO, 2012b).”

Leveraging the strengths of all talents

The second edition of the Gender Diversity Booklet underscores that

diversity and inclusion training can make a company more productive. They encourage employees to open their minds to new perspectives and eliminate biases and stereotypes, improving, at the same time, productivity and communication within the company, employee cooperation, creativity, and out-of-the-box thinking.

On the other hand, a lack of psychological safety can have far-reaching repercussions. Seafarers who are afraid or uncomfortable to speak up, and do not feel appreciated by their company, may not point out or admit to errors and lack the motivation to take the initiative to fix or stop mistakes. If workers are not fully committed, the company is unable to “leverage the strengths of all its talent,” and productivity suffers.

The survey also asked respondents for their suggestions on how to address the issues brought up in the questionnaire. The responses included, among others, creating an environment of trust and respect; providing equal opportunities, equal pay, and fair treatment; encouraging more women to work at sea, to be present on the board and in leadership positions; creating an environment where women feel comfortable reporting issues and complaints; bringing about transparency in hiring procedures; providing training on gender sensitisation and eliminating unconscious bias and discrimination; and making fair evaluations based on work performance alone.

The Gender Diversity Booklet also pre sented some steps encouraging psychological safety at the workplace, founded on cultural awareness, anti-harassment and anti-bullying policies. An all-inclusive workforce must include diverse teams drafting company policies which must have “buy-in at all levels” to ensure commitments to policy implementation even at the highest levels. The policies must include an action plan “with clear and measurable time-bound targets to support the implementation of the policy.”

For a company to thrive, it is crucial to develop and implement unbiased recruitment processes, cultural awareness, and prevention of harassment and bullying. The hiring process must be gender-blind with a focus on skills and experience. The interviewing panels must be diverse, job descriptions need to be gender-inclusive, and hiring procedures should be reviewed continuously. There must be no bias against any gender, race, religion (or the absence thereof), or nationality in the hiring process, as well as in the workplace itself; the working environment must be rooted in mutual respect among all employees, free of harassment and discrimination.

One of the most effective ways to prevent harassment and bullying is to investigate all complaints immediately while taking prompt action to rectify the situation. This sends a clear message of what type of behaviour will not be tolerated at the company. “Strict disciplinary action

A deck cadet on board a container: “female sized coveralls!! We are not shaped like boxes!!!! Also, on my ship we never had size ‘small’ of anything! Let alone an XS!”

must be taken against offenders, and assistance should be provided in reporting to authorities/criminal justice system.”

Also, all the workers must take action to prevent harassment and report it if it occurs. It is imperative to protect those who file complaints against victimisation. It is equally important to clarify that “malicious complaint and false/forged evidence may result in legal and/or disciplinary procedures.”

A necessity

Gender diversity is only possible if it is a company-wide effort; therefore, it needs to be visible, particularly in the organisation’s senior positions. For example, senior personnel should be transparent about company diversity challenges or complaints and address them instantly. The efforts to strengthen gender diversity should include setting diversity goals, encouraging referral programmes, and consciously hiring more women.

for promotion and, if possible, year-round employment to sustain women in the maritime. Further, it is vital to provide women seafarers with mentoring programmes where females in higher positions offer support and guidance to new hires. This can be initiated by giving a conference guidance call from female senior employees for women cadets just joining the ship for the first time. A 24/7 hotline for women seafarers should also be available.

recognising and nominating women role models within the organisation.

A lack of psychological safety at work has major repercussions. When people don’t feel comfortable there seems to be dangerous silence. The seafarers may feel uncomfortable talking about the possible errors in the system and may lack initiatives. When people are not fully committed, the organisation has lost an opportunity to leverage the strengths of all its talent. When

It is essential to track the progress of female hires and provide opportunities

The Gender Diversity Booklet also advises that gender sensitisation should be included in the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers. The process of gender sensitisation targets societal stereotypes about men and women as “unequal entities” and the misconception about their roles. Since in the maritime there still is a mindset that females are not capable of doing certain tasks, it is essential for employers to empower women by offering company initiatives, rewarding achievements of female employees, and

The survey results of the second edition of the Gender Diversity Booklet underscore that to benefit from all that a diverse workplace offers, the maritime sector-wide must become more welcoming to women seafarers. Research shows that workplace diversity is something top candidates desire when searching for work, which means that attracting top talent to an organisation depends on it. A diversified workforce also signals to investors that the company is wellmanaged and engages in commonly-recognised best practices (studies even show an increase in stock prices after a company wins a diversity-related award ).

But perhaps most convincingly, statistics from educational organisations and workplaces across the globe show that women are coming into the maritime. Enabling them to join the ranks trouble-free is not only the right thing to do; it’s not even what will ultimately pay off. It is a necessity – whether one likes it or not.

that happens, productivity suffers.

employees feel psychologically safe at work, they feel comfortable being themselves and are likely to:

Try new things

Ask for assistance

Express ideas and opinions

Appreciate and respect others

Show empathy and concern

in resolving conflicts

How will bio-LNG stack against other marine fuels in shipping’s race towards sustainability

Hit the (bio)gas

by Steve Esau, COO, SEA-LNGThe bio-version of liquefied natural gas (bio-LNG) can meet a significant proportion of future shipping demand and will be among the cheapest sustainable alternative marine fuels. In its pure form, bio-LNG could cover up to 3% of the total energy demand for shipping fuels in 2030 and 13% two decades later. As a drop-in fuel blended (20%) with fossil LNG, it could cover up to 16% and 63% of the total energy demand in 2030 and 2050, respectively.

That is one of the key predictions made in a new independent report conducted by Nanyang Technological University’s Maritime Energy and Sustainable Development Centre of Excellence. The report also forecasts that the average cost for delivered bio-LNG will fall by 30% by midcentury vs today’s values, mainly driven by the reduced expense of producing biomethane in large-scale anaerobic digestion plants. This makes bio-LNG one of the cheapest sustainable alternative marine fuels, compared to biomethanol and electro-fuels, including e-ammonia and e-methanol.

The study, commissioned by SEA-LNG, confirms that bio-LNG has considerable potential as a solution for the decarbonisation of the shipping sector thanks to the mature and commercially available technologies for fuel production and use onboard, existing delivery infrastructure, plus its competitive cost compared to other sustainable biofuels and electro-fuels.

Growing demand – and supply

The LNG-fuelled fleet is growing rapidly, with vessels propelled by dual-fuel engines representing some 38% of all tonnage on order. Owners and operators of gas-fuelled ships worldwide (such as CMA CGM, Furetank, Baleària, TT-Line, UECC, Tote, and Harvey Gulf International) have all used bio-LNG bunkers in response to upcoming regulation and customer demand.

We are already seeing a growing number of strategic collaborations driving the development of bio-LNG production forward: Scandinavian Biogas, for example, has just signed a multi-year agreement worth approximately three hundred million Swedish crowns for the supply of liquid biogas to the transport sector in the Nordic region. Energy company St1 has made an investment decision to construct a biogas upgrading & liquefaction refinery in Sweden after securing long-term offtake contracts, while Latvia’s Agrofirma Tervete to supply equipment for a bio-LNG production plant in the Latvian Tervete.

Meanwhile, Gasum’s network already counts 17 biogas plants across Finland and Sweden, with the company regularly supplying bio-LNG bunker to regional players.

Sustainable sources

Bio-LNG is derived from the liquefaction of biomethane. This gas is produced from the degradation of second-generation biomass, including non-food energy crops, agricultural residues, manure, biowaste, and wood and forestry waste. As a second-generation fuel – unlike most biodiesel – its production will not interfere with food, fodder or fibre supply chains, and its production avoids land use changes.

Importantly, when manure is used as a feedstock, biomethane production avoids releasing methane emissions into the atmosphere. Current management practices involve using manure as a fertiliser on crop fields, where it decomposes, venting methane into the atmosphere.

In general, bio-LNG can reduce greenhouse gas emissions by up to 80% vs marine diesel – if methane leakage in the production process and onboard methane slip are minimised. In the case of bioLNG produced from anaerobic digestion of manure, if avoided emissions are considered, then bio-LNG can achieve negative emissions ranging from -121% to -188% compared with diesel.

Cost comparison

Although the cost of bunker bio-LNG is relatively high compared to fossil fuels, it is cheaper than most other alternative fuels. In the best-case scenarios, where biomethane is produced from manure and agricultural residues in Asia and delivered to major eastern ports, the cost of bio-LNG could fall to $20/GJ by 2030 and $15/GJ by 2050.

Sustainable biofuels such as UCOME made from waste cooking oil are generally cheaper. Still, feedstock availability is low.

Biomethanol and bio-LNG have similar costs per unit of energy, with the former being slightly more expensive due to the gasification technology required in its production.

Electro-fuels will be significantly more expensive than biomass-derived fuels. Among these e-fuels, liquid e-hydrogen has the lowest production costs; however, its high transport and delivery costs make it the most expensive bunker fuel. The production costs of e-methanol and e-LNG are similar and have comparable costs for transport and bunkering per unit of energy. It should also be remembered that while a gallon of methanol is cheaper to store and transport compared to an equivalent volume of LNG, it carries far less energy due to its lower energy density.

E- ammonia is generally cheaper to produce as, unlike e-methanol and e-LNG, its production does not require CO2 . That said, there are major uncertainties about fuel handling systems and engine technologies, which are only at the research or pilot stage. Further data on onboard conversion system costs and efficiency are needed before e-ammonia’s cost competitiveness can be determined.

Future availability

The adoption of bio-LNG in shipping will be linked to the widespread use of biomethane across other sectors to grow the overall supply pool. It will require regulation in two key areas. Firstly, national and international standards for biomethane injection into gas grids. Secondly, a commonly accepted, preferably legally binding, certificate of origin scheme to facilitate efficient trading in biomethane in its gaseous and liquefied forms and reduce transportation costs.

Logistics considerations

The upstream production costs of biomethane can be reduced by optimising the size and location of future biomethane plants by reducing the cost of biomass collection and transport. The best-case scenario is represented by medium-sized plants close to farms and biomass waste collection points, such as cities for food waste and slurry, animal farms for manure, and agricultural sites for residues.

Fig. 1. Potential availability of bio-LNG for the shipping sector in 2030 and 2050 over total shipping energy demand, with different blending rates with fossil LNG

Fig. 2. Scheme for the evaluation of bio-LNG availability for shipping

Source for all figs.: SEA-LNG

Fig. 3. Bio-LNG from anaerobic digestion total cost range in 2020, 2030 and 2050, compared with fossil LNG bunker price

Fig. 4. Alternative fuels energy cost comparison (per unit of output energy from the engine)1, 2, 3

Dedicated supply chains for shipping involving on-site liquefaction and transport of bioLNG by trucks and bulk carriers are appropriate for demonstration purposes. Still, they do not make economic sense for large-scale implementation due to very high infrastructure costs. Utilising existing LNG infrastructure and logistics should therefore be incentivised.

The lowest costs are achieved when biomethane is injected into the gas grid and virtually transported to liquefaction plants and LNG terminals using existing infrastructure and instruments such as Green Gas Certificates and Biomethane Guarantees of Origin for trading. This would require

1 Including transport & bunkering costs (bio-LNG and e-LNG transport cost is based on fossil LNG, thus implying the use of existing infrastructure)

2 Assumed engine conversion efficiency: 45% (50% for liquid hydrogen used in a fuel cell)

3 The higher and lower ends of the spectrum represent 2030 and 2050 costs, respectively

an appropriate regulatory framework like that already in place for green electricity in some regions of the world, including Europe.

Part of the mix

The global shipping industry faces unprecedented challenges as the pressure to meet climate targets grows. Over the next

couple of decades, alternative fuels and propulsion systems may emerge. However, LNG is, for the moment, the only commercially viable and scalable alternative marine fuel, offering the shipping industry a low-risk and incremental pathway to decarbonisation, starting now and continuing through bio- and e-LNG into the future.

Founded in 2016, with numerous high-profile members including shipping companies, ports, LNG suppliers, bunkering companies, infrastructure providers, original equipment manufacturers, classification societies, banks, and brokers, SEA-LNG is a multi-sector industry coalition whose members work together to demonstrate the benefits of LNG and its variations as a marine fuel throughout the entire value chain. Head to sea-lng.org for more info.

The risks of unconventional cargo carriage

A bad idea?

by John Southam, Loss Prevention Executive, and David Richards, Director Claims, North P&I ClubAmid a shortage of container ship capacity and soaring rates for transporting containerised freight, carriers are increasingly exploring alternatives, including the potential for getting bags, flexible intermediate bulk containers or intermediate bulk containers on board dry bulkers. While more and more bulk carrier operators are considering carrying cargoes that would usually be containerised, not all goods are suited to this shipping method. Those still willing to explore the opportunity should be aware of the associated risks.