Traditional hash has been made and smoked for thousands of years. Unlike hash rosin, the trichome heads are not de-waxed by pressing the rosin through 25-micron bags. Instead the trichomes (kief) are worked into a malleable resin that is combusted in joints, pipes or mixed with tobacco and rolled into spliffs. Traditional hash is typically in the 30-60% THC range, while hash rosin usually tests at 60-80% THC.

I have many friends that don’t like cannabis but enjoy hashish. They attribute this to the fact that hashish does not get them “too high” or “anxious” as cannabis can sometimes do to infrequent users. Traditional hash aficionados look for a product that does not have a weed like smell, but rather smells like “hash”. The Trichome Research Initiative has postulated that this characteristic hash smell is caused by the degradation of the terpene myrcene. Whatever the cause traditional hash requires a long curing time (6-12 months) to allow the flavours to fully develop and amalgamate. This is in contrast to hash rosin which is typically best after a quick 1-2 week cure.

For growers and extractors having a “traditional hash” in the product catalogue is a no brainer. It is a low cost product which retailers are more inclined to keep in stock, and if the Canadian market is any indication for how new markets will develop it is a product that sells extremely well.

The late Frenchy Cannolli infamously used wine bottles filled with hot water to press his hash into a resin. The process below uses a stainless steel meat ginder to press and work the bubble hash/dry sift into a resin. There are many different ways to do this but at scale meat grinders work well. The idea is you use heat and pressure to partially decarboxylate the hash, which facilitates its transformation into a resin.

Although you can make traditional hash using ice water extracted bubble, it is much more cost effective to use dry sift from a Cannabis Tumbler for this process. The Hashtek made cannabis tumblers are perfect for this application at scale. You can sift flower or trim to get dry sift, with the trim obviously being the more economical option. It always surprises me how many growers throw away their trim or sell it for pennies on the dollar.

Items Needed:

- Keif (extracted with Cannabis Tumbler)

- SS Meat Grinder

- Pre Press

- Turkey Bags

Process Overview

- Sift Trim/Flower into Kief

- Run Kief through meat grinder

- Press into bricks

- Cut up the hash and package

Start with your Kief that you have collected from the Hashtek Cannabis Tumbler or by other means. Kief should be processed immediately after sifting to reduce oxidation and terpene loss. If there is a time delay between sifting and processing the kief should be frozen or refrigerated.

Kief is the only input material so any COA’s from your input material should be a good indication of your final potency.

A coarse 3/8″ plate is what you want to use when making hash with a meat grinder. Anything smaller like the 1/8″ plate below will clog too easily.

The kief will need to be run through the grinder 2-10 times to get the desired consistency. Colour of the hash is the best indication of how much you need to work it. As shown in the pictures below the pellets comings out of the grinder will begin to darken and turn brown. When it becomes sticky and malleable your hash is ready to load into the pre-press.

The fresher your material, the less it will need to be worked. When it starts to looks and feel like play-doh you are getting to the right consistency.

The pellets picture below in the middle are ready to be pressed. The ones on the right need to be fed through the meat grinder a few more times to darken up.

The Pure Pressure ‘long peak’ press pictured below is not my favourite press to use, especially for this application. The plates do not open far enough to allow a fully loaded press to be fit inside. I would recommend investing in a Sasquatch press if you don’t have one already.

The press below is a 2×9″ pre-press and holds about 100g of hash. Press time and temperature will vary depending on your material. I typically press pretty hot (180-220C) as the pre-press is usually quite thick and acts as a thermal barrier.

If your hash begins to ooze out of the press you need to turn the temperature and pressure down.

If the hash does not press into a clean brick you need to turn the temperature up.

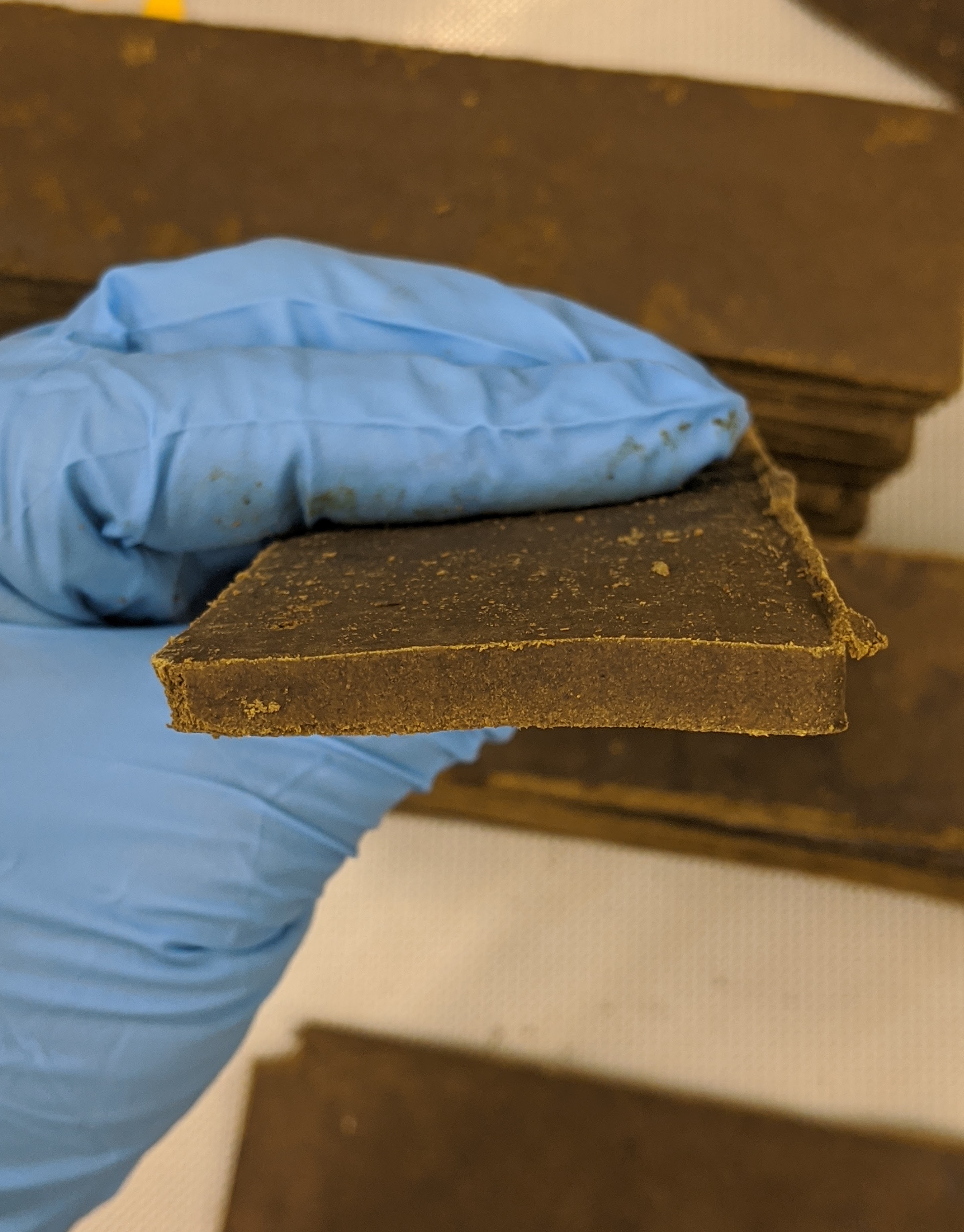

The result should be something as shown below.

When running higher quality material (closer to full melt) only one pass through the meat grinder is required. As shown in the video below the hash comes out almost like warm nutella that solidifies when it cools. Best stored wrapped tightly in cellophane or turkey oven bag plastic and then stored in a secondary air tight container.

Happy hash making!