Laminated solenoid armature for an electromagnetic activation device and injection valve for metering a fluid

An electromagnetic actuation, layered technology, applied in the direction of electromagnets, magnets, valve devices, etc., can solve the problems of cumbersome device manufacturing and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

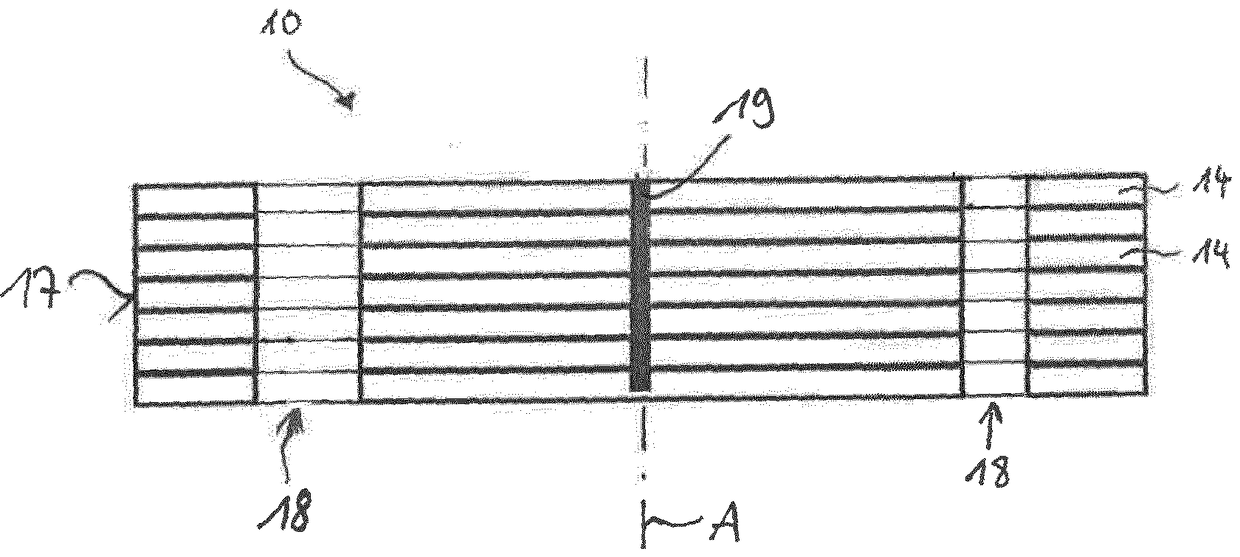

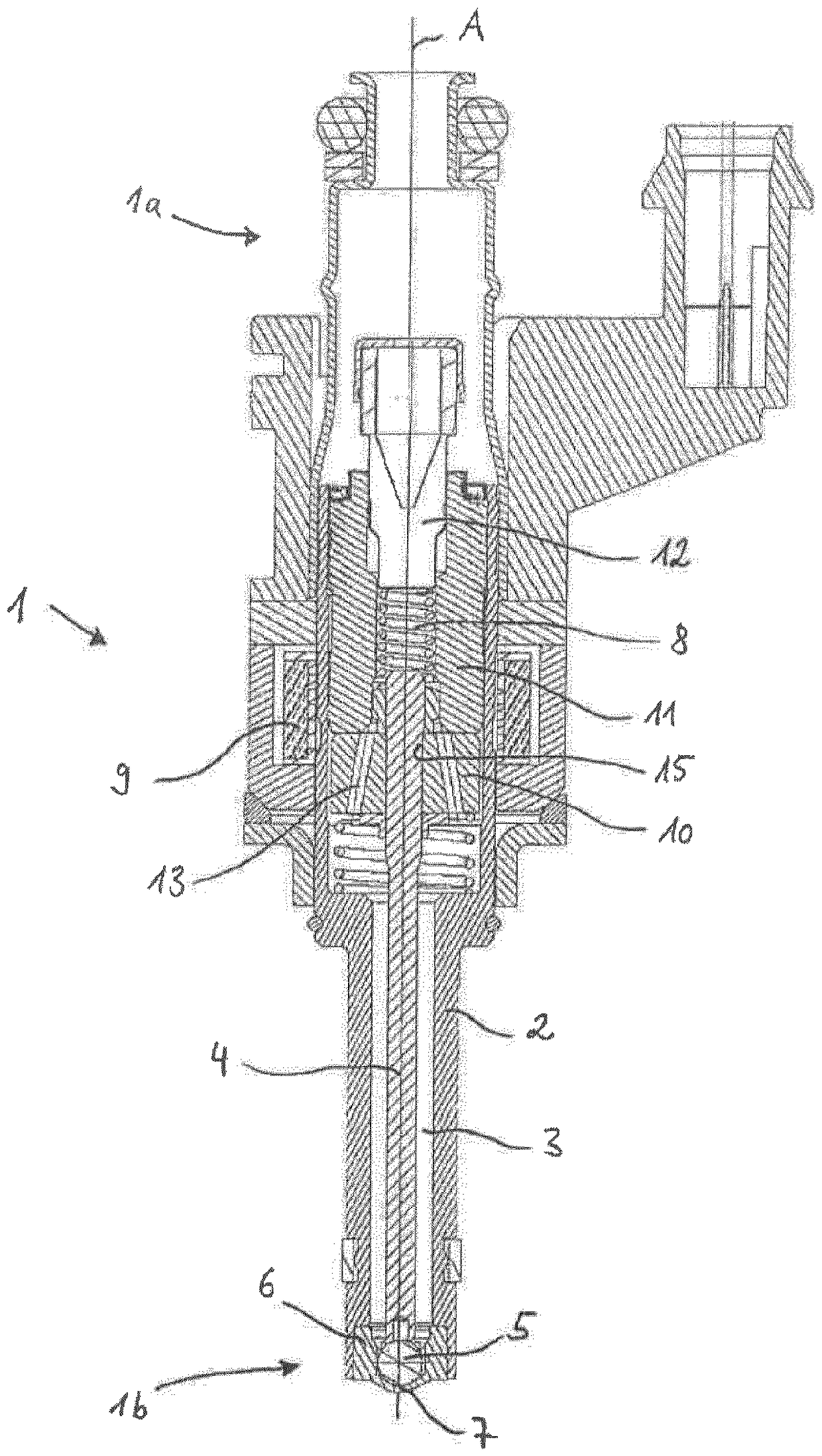

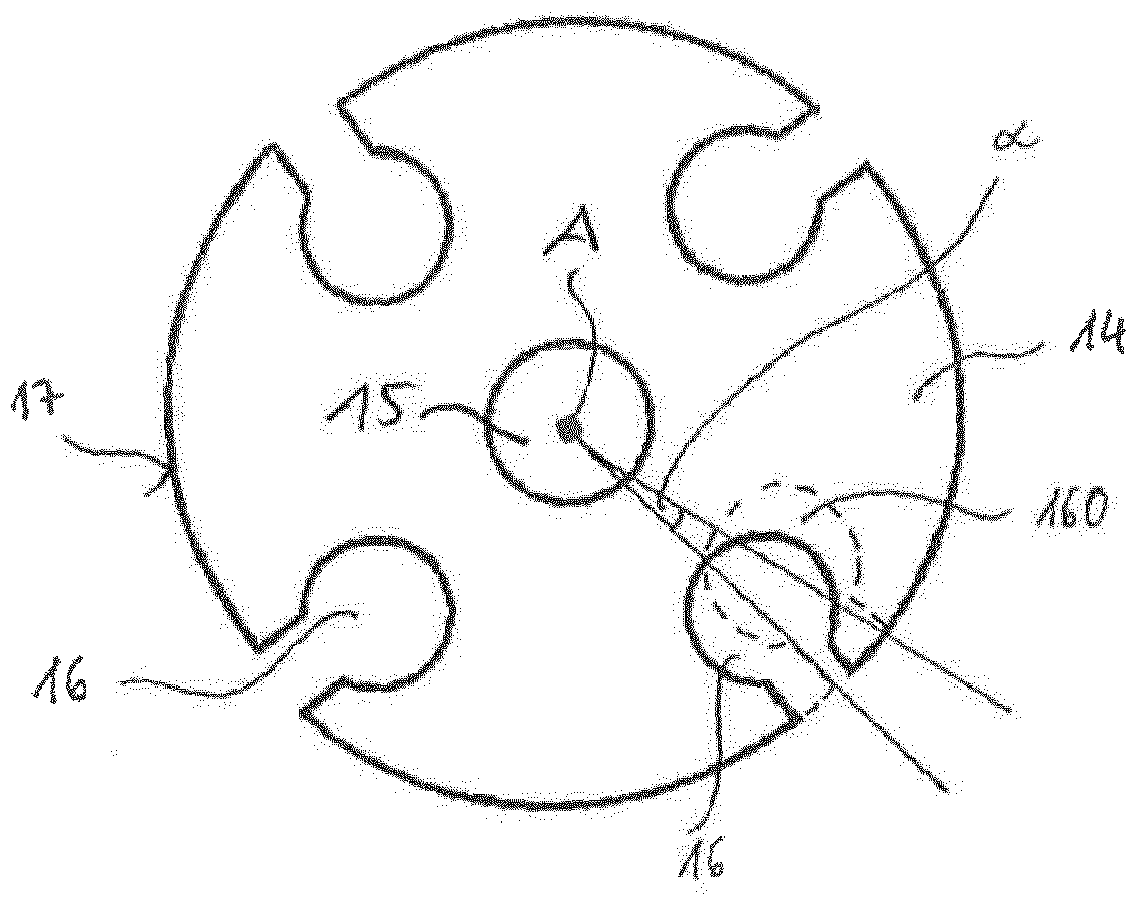

[0029] figure 1 Shown is an injection valve 1 known from the prior art, such as, for example, an injection valve for injecting fuel into an intake port or a combustion chamber of an internal combustion engine.

[0030] Injection valve 1 has a fluid inlet port 1 a and a fluid outlet port 1 b and comprises a valve housing 2 surrounding a cavity 3 . The valve needle 4 is arranged in the cavity 3 . The valve needle 4 is displaceable along the axis A relative to the valve housing 2 . On its end facing the fluid outlet port 1 b of the injection valve 1 , the valve needle 4 has a closing element 5 in the form of a ball, with which the valve needle 4 can be accommodated in a valve seat 6 . The valve seat 6 has an opening 7 which can be opened or closed by the closing element 5 of the valve needle 4 . If the valve needle 4 is moved into its position which opens the opening 7 , the fluid for metering can exit the injection valve 1 through the opening 7 . If valve needle 4 is in its ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap