ICCP or sacrificial anodes?

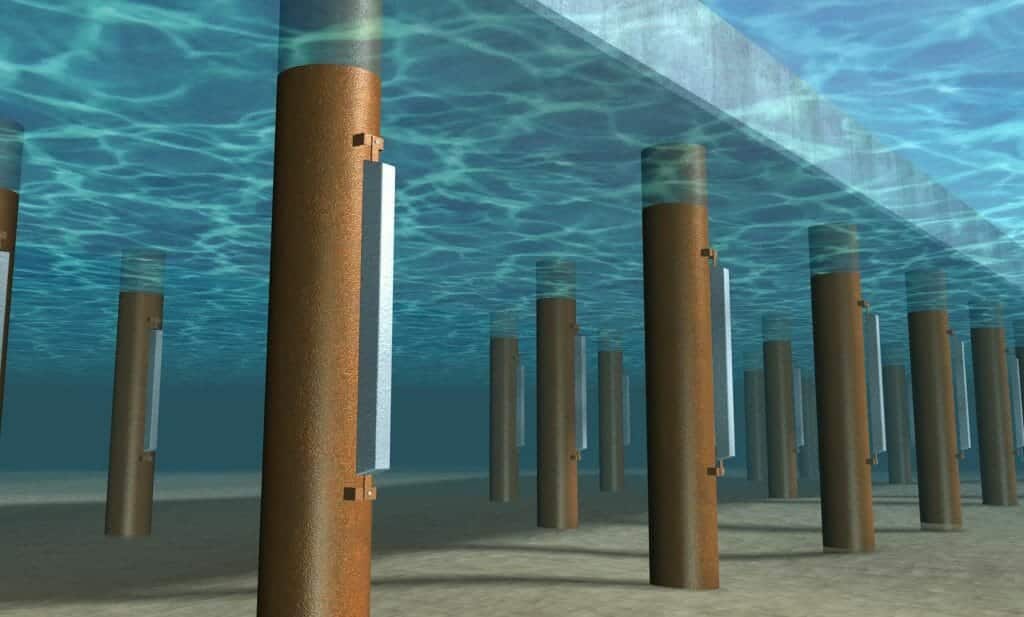

Submerged sheet pile walls and tubular support piles can be protected agains corrosion by either sacrificial anodes or impressed current cathodic protection (ICCP).

ICCP in brackish water

Compared with sacrificial anodes, ICCP anodes can provide signficantly more protective current at a higher driving voltage. This increased capacity is often a necessity to maintain protection (polarisation) in low conductivity conditions, such as in brackish water.

In seawater conditions with normal salinity, cathodic protection is mostly executed by means of sacrificial anodes.

You may also want to read about

Durability

Cathodic protection by ICCP includes several components, like control panel, submerged anodes, reference cells, junction boxes and cabling. Sacrificial anodes are basically rugged active metals welded or bolted directly on the steelworks below tide level.

You may also want to read about

As ICCP systems are more prone to component failure, a safety factor is generally required to maintain reliable operation, especially in exposed areas with ice, harsh weather conditions or propeller flow. Sacrificial anodes are more robust and resistant to such mechanical exposure.

Anode capacity

ICCP anodes are either inert (no inherent power) like the mixed-metal-oxide (MMO) coated titanium rods, or they are semi-intert like the silicon/chromium/iron (FeSiCr) rods. MMO coated anodes have a capacity typically between 50 and 100 A each, whilst the FeSiCr anodes generally have less than 30 A capacity each.

CathSense® ICCP system for corrosion protection of harbours.

Aluminium anode alloy has an electrochemical capacity of about 2500 Ah/kg, depending on the compositon and production method. Current output capacity for harbour anodes is typically between 2 and 3 A each, with a driving voltage in the range 0.25 to 0.3 V.

Capacity of aluminium anodes from Cathwell.

You may also want to see

Remote anode sleds

The use of anode sleds has proved to be a cost-effective alternative to adjacent anodes for harbour projects. It greatly reduces the installation time and facilitates a safer installation process, at a significantly reduced investment cost. Remote anode sleds provides also the best distribution of protective current.

Anode sleds are, however, more challenging when it comes to interference. For ports with frequent ship calls, remotely arranged anodes are not recommended due to possible detrimental interference.

Sacrificial anodes have limited or no interference effect on ships or neighbouring structures.

Installation

Sacrificial anodes can either be welded directly on the steelworks or mounted on special brackets to allow for future exchange. Sacrificial anode bracket can be pre-welded prior driving down the sheet piles.

You may also want to see

Installation of ICCP requires assistance from divers, electricians and civil contractor.

Cathwell will generally provide installation drawings and recommendations in connection with provision of cathodic protection for harbour projects.

You may also want to see

Operation and maintenance

A sacrificial anode system is basically self-adjusted and maintenance free. However, periodic reference potential surveys should be undertaken to verify the level of protection.

An ICCP system can be set up with automatic protection adjustement. Regular maintenance is, however still required. A maintenance survey would include reference potential measurement, component testing and adjustments.

Lifespan and replacement

Alltough sacrificial anodes can basically be designed to last as long as desired, the design lifetime for harbours structures is usually between 10 and 30 years.

A reasonable design lifetime of ICCP systems is 20 years.

You may also see